Collection tank and corresponding heat exchanger

A heat exchanger and collection box technology, applied in the direction of heat exchanger fixation, heat exchange equipment, heat exchanger shell, etc., can solve problems such as the difficulty of inserting heat exchange tubes into the head, and achieve the effect of reducing pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

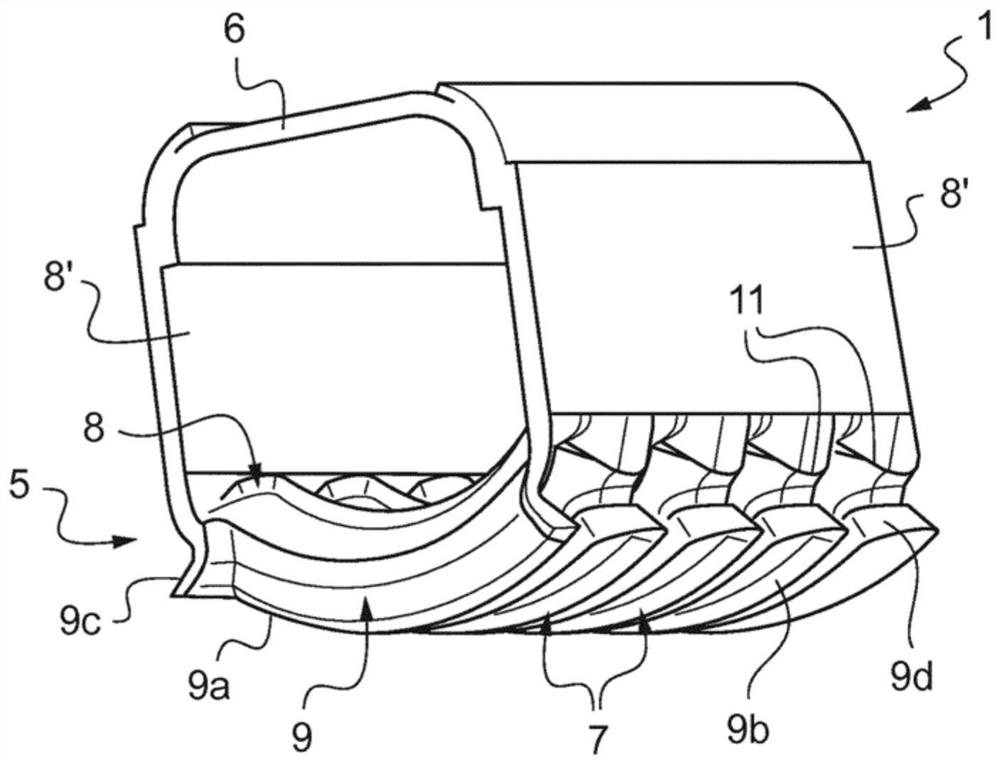

[0045] figure 1 is a simplified schematic diagram showing a fluid collection tank 1 for a heat exchanger (not shown), used in particular in the motor vehicle sector. The heat exchanger can be used in particular as a radiator or as a condenser of a motor vehicle.

[0046] In particular, the invention can be applied to brazed heat exchangers.

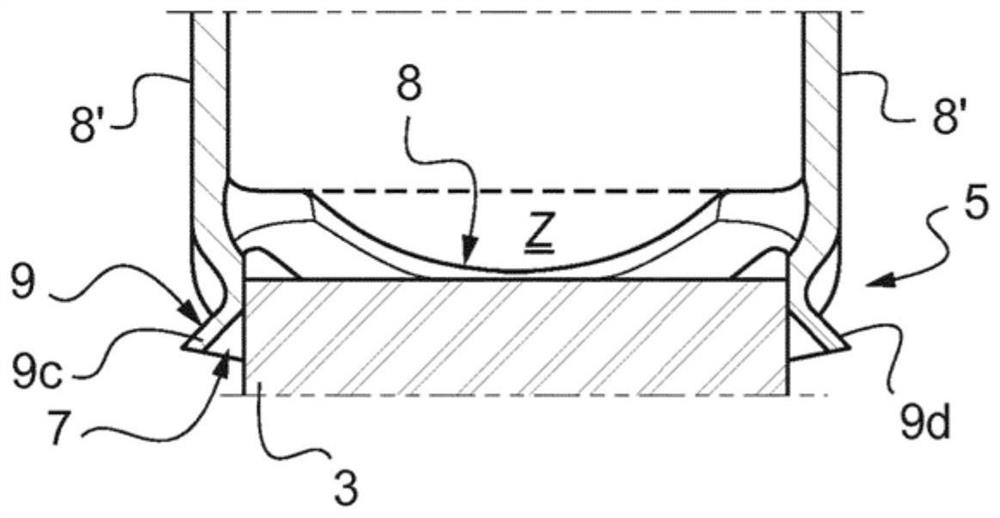

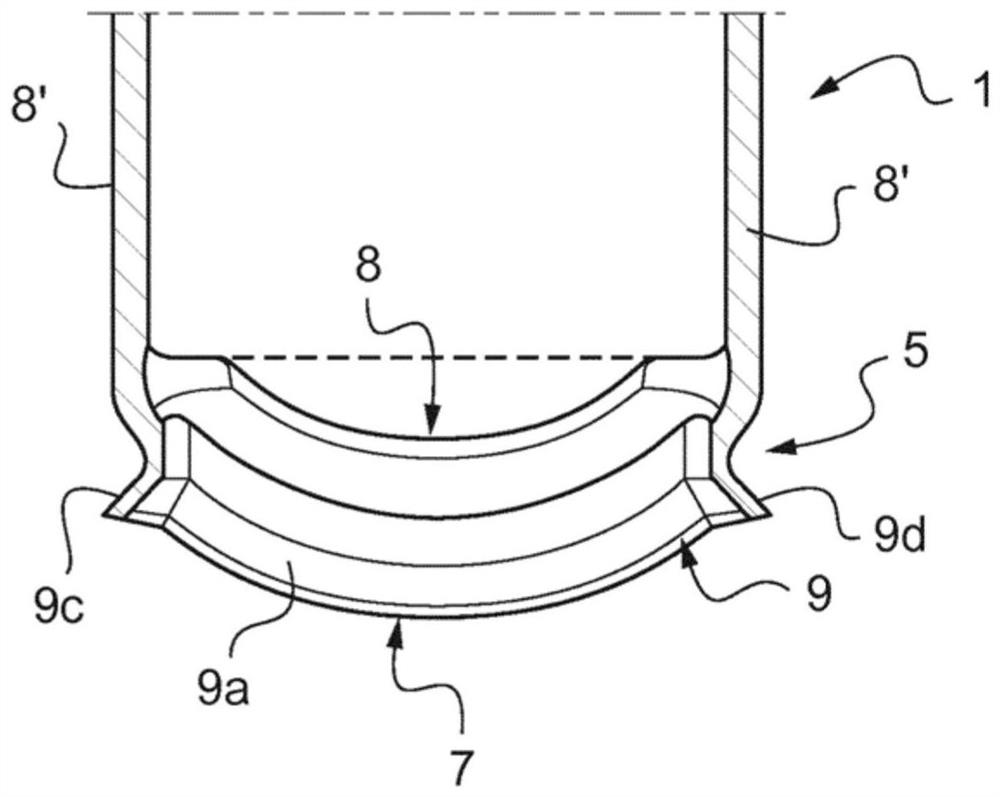

[0047] The heat exchanger comprises a core tube bundle 3 . exist figure 2 , only one end of one tube 3 is visible. The tube 3 is made, for example, of aluminum or an aluminum alloy. These are, for example, approximately flat tubes 3 .

[0048] The collecting tank 1 is configured to receive at least one end of a tube 3 of a heat exchanger, more specifically, the ends of a plurality of tubes 3 in a heat exchanger (not shown). exist figure 2 , only one end of one tube 3 is visible.

[0049] To this end, the collection box 1 comprises a head 5 . The collection box 1 additionally comprises a lid 6 secured to the head 5 to close the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com