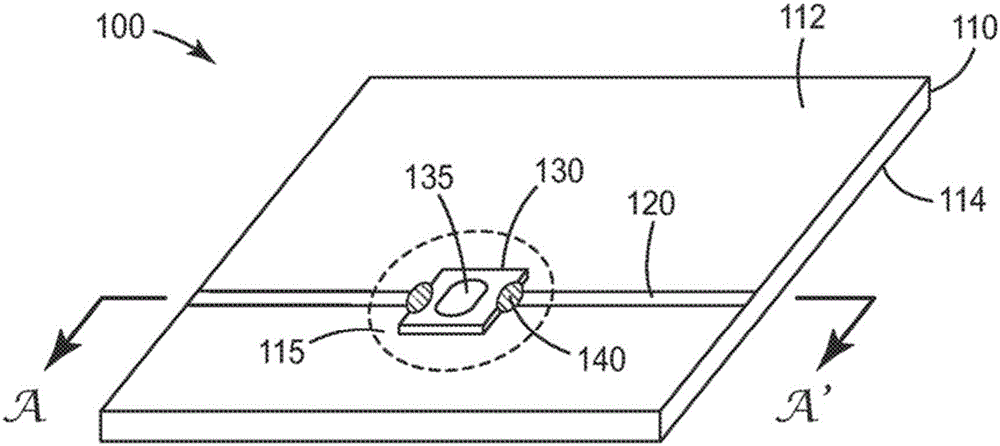

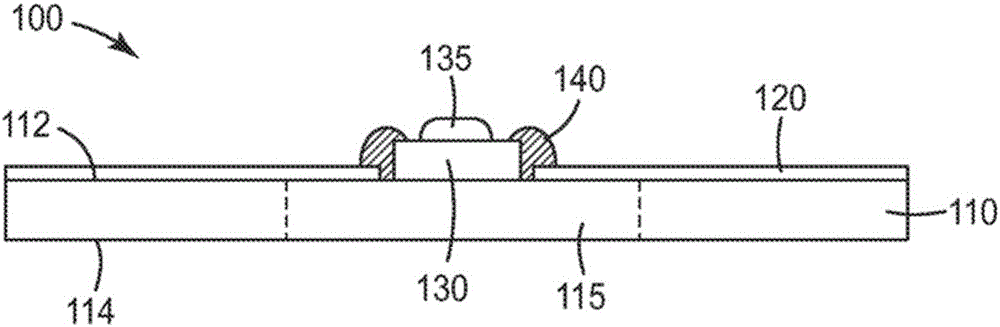

Flexible circuit on reflective substrate

A flexible circuit and reflective film technology, which is applied in the direction of circuits, electrical components, electric solid devices, etc., can solve problems such as short circuit of circuit board conductors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A silicone polyoxamide-based mirror having polyethylene terephthalate (PET) as a high Refractive index material and skin and polydiorganosiloxane-polyoxamide thermoplastic silicone elastomer as 275 alternating layers of low refractive index material. A "bond" layer of about 5 nm of chromium was deposited on the silicone polyoxamide-based mirror, and then a "seed" layer of about 250 nm of copper was deposited on the "bond" layer, both using a Batch coater. The copper is then plated using an electroplating process to a thickness of approximately 18 microns to 20 microns of copper. Pattern the LED circuit onto the copper surface and film. The circuit is approximately 230mm long with two power busses approximately 1mm wide and spaced approximately 10mm apart connecting the LED circuit running between the buses. Etching the film in a ferric chloride bath to remove unpatterned copper, and then etching the film in a mixture of potassium permanganate and potassium hydroxide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com