Potato washing machine with two-stage cleaning and water removal collection functions

A potato washing machine and wastewater collection technology, applied in cleaning methods and utensils, cleaning methods using liquids, solid separation, etc., can solve problems such as inconvenient maintenance, achieve low equipment production costs, reasonably control dehydration equipment costs, The effect of improving the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

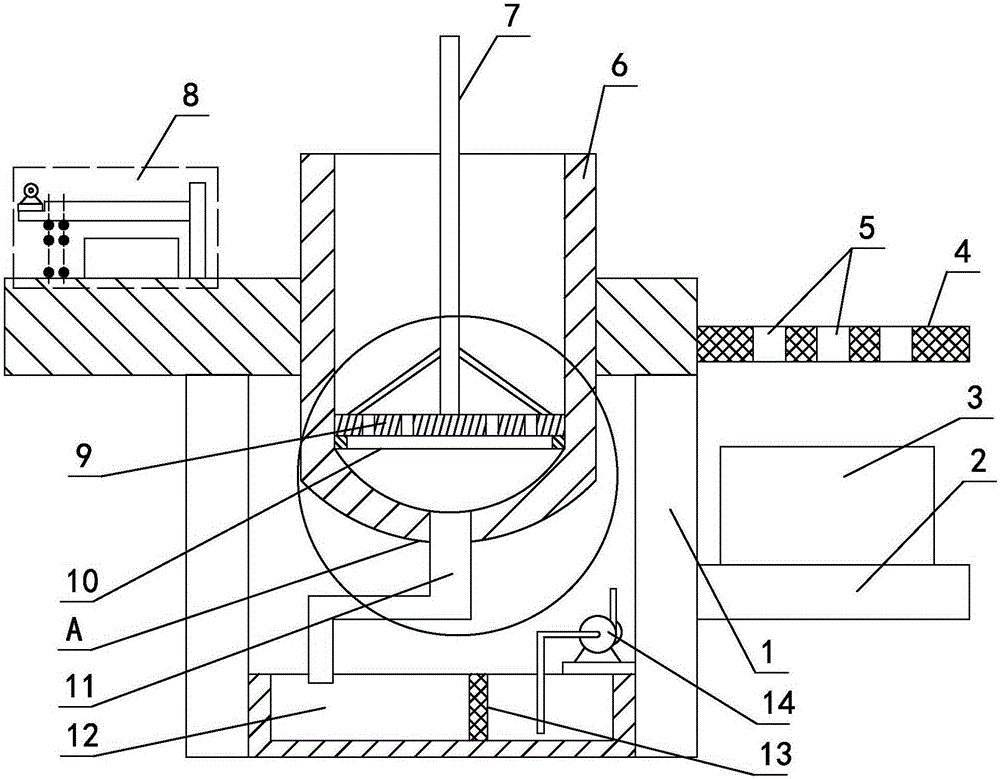

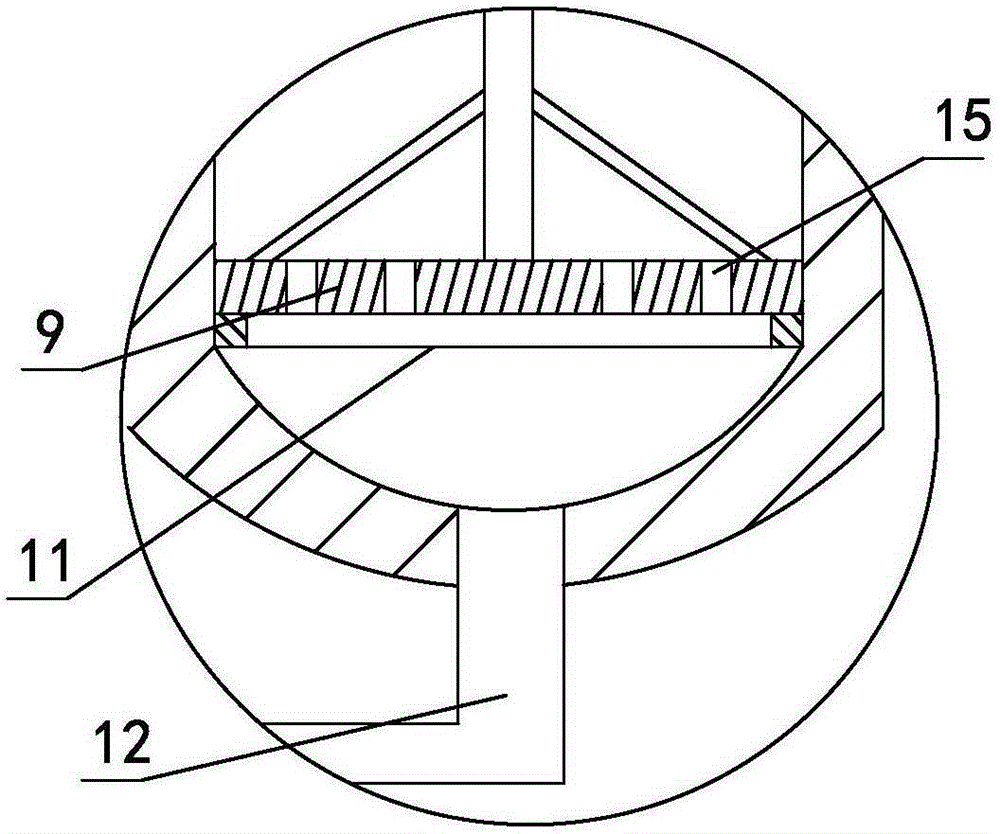

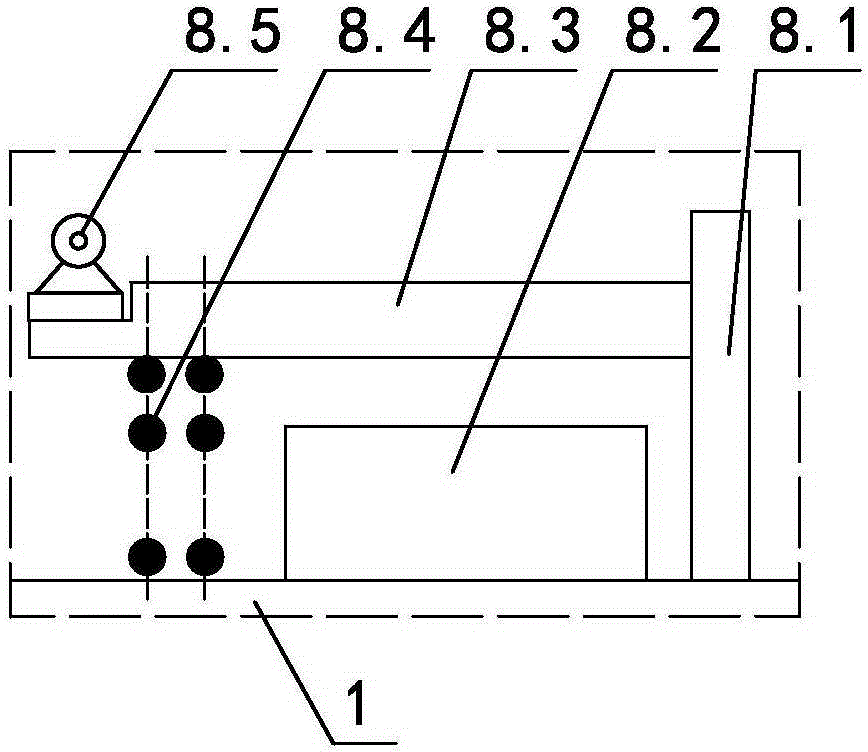

[0027] like figure 1 , figure 2 , image 3 As shown, the potato washing machine for two-stage cleaning and dehydration collection includes a workbench 1, and a cleaning bucket 6 is vertically installed on the workbench 1, and a drain line 11 is arranged at the bottom of the cleaning bucket 6. A lifting plate 9 that moves up and down is provided. The top of the lifting plate 9 is provided with a lifting rod 7 for moving the lifting plate 9 up and down. A number of drainage holes 15 are opened on the lifting plate 9. The drainage end of the drainage pipeline 11 is provided with waste water. The processing mechanism, on the workbench 1 on the left side of the cleaning bucket 6, is provided with a soil sorting mechanism 8 for removing soil for the first time, and a drying plate 4 is horizontally fixed on the right side of the workbench 1. The drying plate 4 is provided with a number of upper and lower connected A dehydration collection tank 3 is arranged directly under the dryi...

Embodiment 2

[0031] On the basis of the first embodiment, the gap between the lifting plate 9 and the cleaning bucket 6 is changed to 20mm; the diameter of the drainage hole 15 is changed to 30mm; the power mechanism includes a hoist, and the hoist is installed through a bracket Above the workbench 1, the rope of the hoist is connected to the lifting rod 7.

[0032] Others are the same as the first embodiment.

Embodiment 3

[0034] On the basis of the first embodiment, the gap between the lifting plate 9 and the cleaning bucket 6 is changed to 15 mm; the diameter of the drainage hole 15 is changed to 20 mm.

[0035] Others are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com