Rope ladder device for maintenance and using method thereof

A rope ladder and steel wire rope technology, applied in the field of rope ladder devices for maintenance, can solve problems such as narrow width and limited operating range of maintenance personnel, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

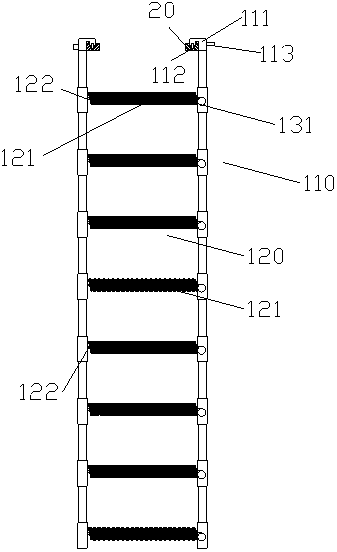

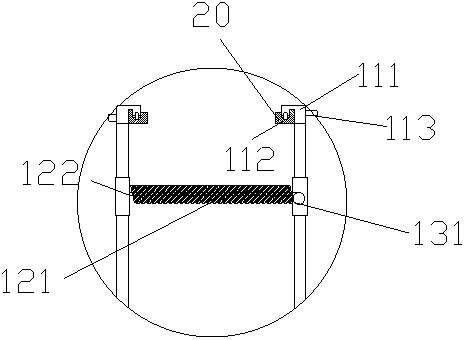

[0016] Such as Figure 1~2 As shown, a rope ladder device for maintenance includes a rope ladder and a guide rail 20 fixed on an inspection tower or a telephone pole. The rope ladder includes a pair of longitudinally arranged longitudinal portions 110 and a horizontal treading portion that connects the two longitudinal portions to form a whole 120. The transverse tread portion includes an outer spiral ferrule 121 and a steel wire 122 arranged in the ferrule 121, and the longitudinal portion 110 includes a longitudinally arranged soft rope and a plurality of longitudinally arranged sleeves fixed on the soft rope. The two ends of the spiral ferrule 121 are respectively fixedly connected to the sleeves on both sides of the longitudinal part. Each sleeve is correspondingly connected with a spiral ferrule 121, and each sleeve is provided with a closed box. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com