Opposed combustion boiler and flue gas recirculation combustion system using the boiler

A technology for hedging combustion and combustion systems, applied in the field of boilers, can solve the problems of thinning of water wall tubes, high temperature corrosion, hazards of safe and economical operation of boilers, etc., and achieve the effects of isolating contact, improving atmosphere, and preventing high temperature corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with specific examples, but the implementation of the present invention is not limited thereto.

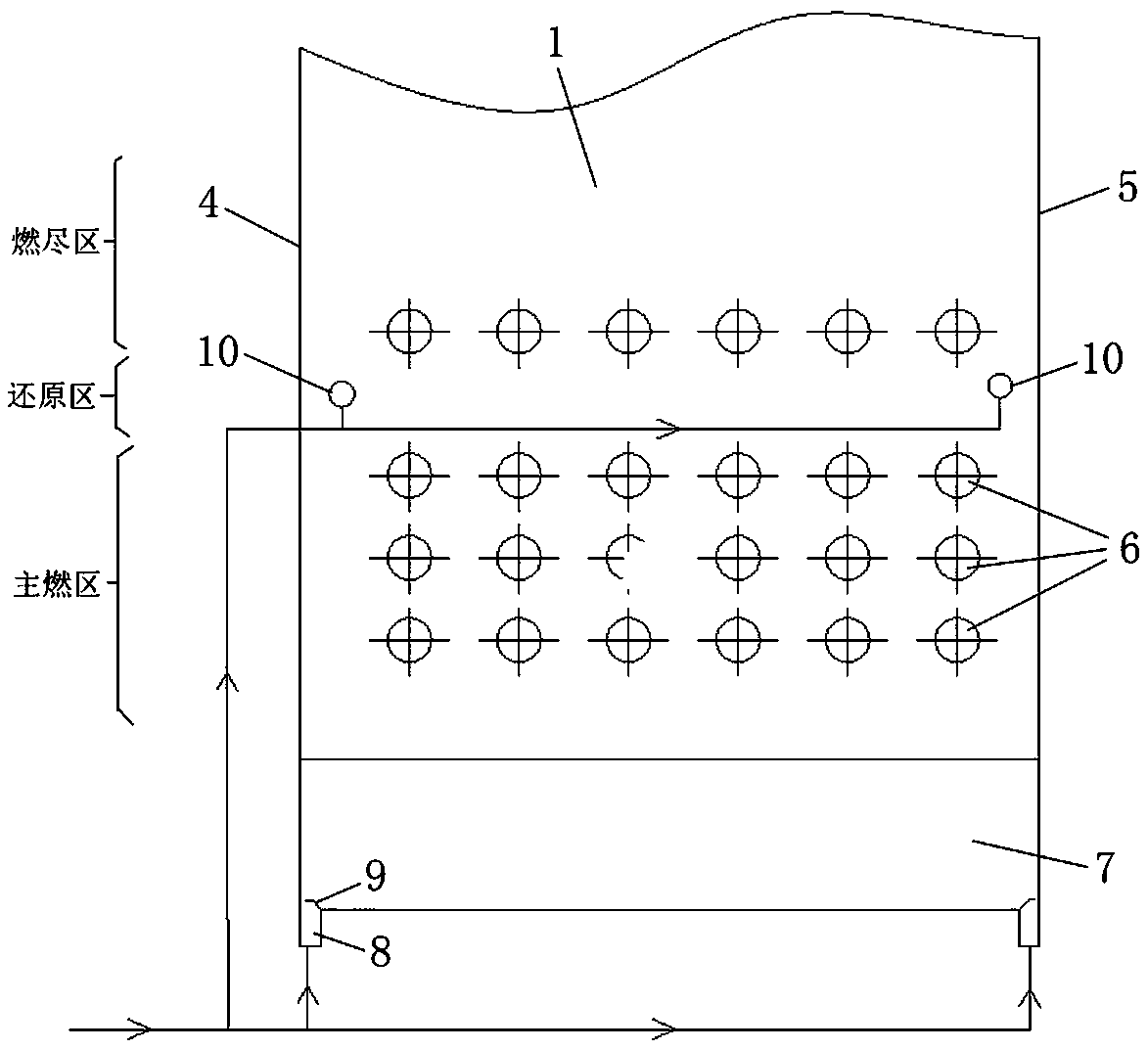

[0020] Such as figure 1 and figure 2 As shown, the opposed combustion boiler of the present invention includes a furnace 1, and the furnace 1 is surrounded by a front wall 2, a rear wall 3, a left wall 4 and a right wall 5. The furnace 1 includes a main combustion zone, a reduction zone and a burnout zone from low to high. Both the front wall 2 and the rear wall 3 are provided with burner nozzles 6 (located in the main combustion zone) and burnout air nozzles 14 (located in the burnout zone). The bottom of the furnace 1 has a cold ash hopper 7, and the bottom of the cold ash hopper 7 is provided with two flue gas inlets 8, which are respectively arranged on the bottom of the cold ash hopper 7 under the left wall 4 and the right side wall 5. The gas inlets 8 are respectively used to introduce ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com