Plastic-dipped electrode product for electric-control solid propellant and preparation method thereof

A solid propellant and electrode technology, used in plastic/resin/wax insulators, anti-corrosion coatings, coatings, etc., can solve the problems of poor high temperature resistance, complex processing technology and weak wear resistance of the insulating layer, and achieve high insulation. Performance, simple preparation process, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

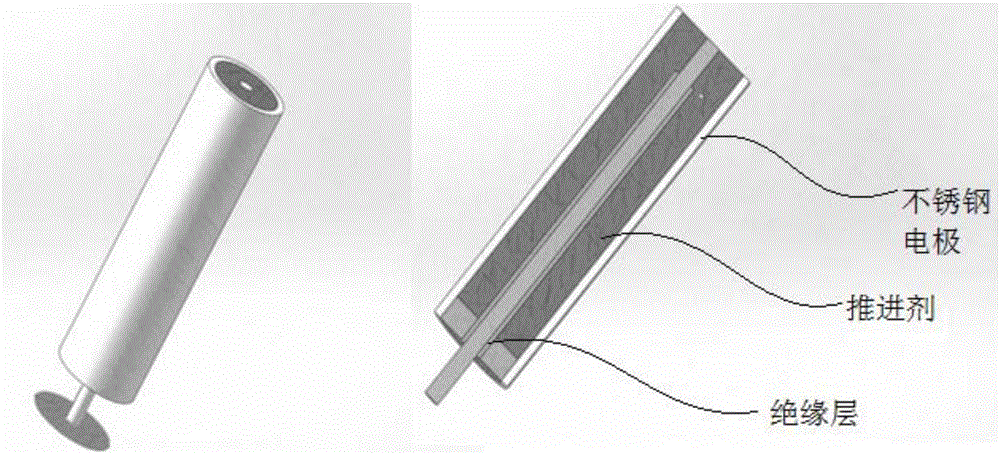

Image

Examples

Embodiment 1

[0040] An electronically controlled solid propellant electrode dip-molding product, characterized in that it includes the raw materials and parts by weight as shown in Table 1:

[0041] Table 1

[0042]

[0043]

[0044] A method for preparing an electronically controlled solid propellant electrode impregnated product, characterized in that it comprises the following steps:

[0045] 1) Pass the phenolic resin or the mixed system in the weighed raw materials through a 120 mesh sieve, disperse evenly, mix with inorganic fillers, plasticizers, and coupling agents to obtain mixture A;

[0046] 2) Add a mixed solvent into the mixture A, and stir under vacuum to obtain a uniformly stirred mixture B;

[0047] The stirring rate is 300r / min, and the stirring time is 60min;

[0048] 3) Add dispersant, defoamer, and leveling agent in sequence to mixture B, stir until mixed evenly, and obtain dipping liquid;

[0049] 4) Under normal temperature conditions, immerse the electrode s...

Embodiment 2

[0055] An electronically controlled solid propellant electrode dip-molding product, characterized in that it includes the raw materials and parts by weight as shown in Table 3:

[0056] table 3

[0057]

[0058] A method for preparing an electronically controlled solid propellant electrode impregnated product, characterized in that it comprises the following steps:

[0059] 1) Pass the phenolic resin or the mixed system in the weighed raw materials through a 120 mesh sieve, disperse evenly, mix with inorganic fillers, plasticizers, and coupling agents to obtain mixture A;

[0060] 2) Add a mixed solvent into the mixture A, and stir under vacuum to obtain a uniformly stirred mixture B;

[0061] The stirring rate is 350r / min, and the stirring time is 60min;

[0062] 3) Add dispersant, defoamer, and leveling agent in sequence to mixture B, stir until mixed evenly, and obtain dipping liquid;

[0063] 4) Under normal temperature conditions, immerse the electrode substrate in ...

Embodiment 3

[0069] An electronically controlled solid propellant electrode dip-molding product, characterized in that it includes the raw materials and parts by weight as shown in Table 5:

[0070] table 5

[0071]

[0072]

[0073] A method for preparing an electronically controlled solid propellant electrode impregnated product, characterized in that it comprises the following steps:

[0074] 1) Pass the phenolic resin or the mixed system in the weighed raw materials through a 120 mesh sieve, disperse evenly, mix with inorganic fillers, plasticizers, and coupling agents to obtain mixture A;

[0075] 2) Add a mixed solvent into the mixture A, and stir under vacuum to obtain a uniformly stirred mixture B;

[0076] The stirring rate is 400r / min, and the stirring time is 40min;

[0077] 3) Add dispersant, defoamer, and leveling agent in sequence to mixture B, stir until mixed evenly, and obtain dipping liquid;

[0078] 4) Under normal temperature conditions, immerse the electrode s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com