High-water-resistance thermal paper and preparation method thereof

A technology of thermal paper and performance, applied in the field of papermaking, can solve the problems affecting the use of paper, and achieve the effect of excellent water resistance and high preservation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0043] Example 1

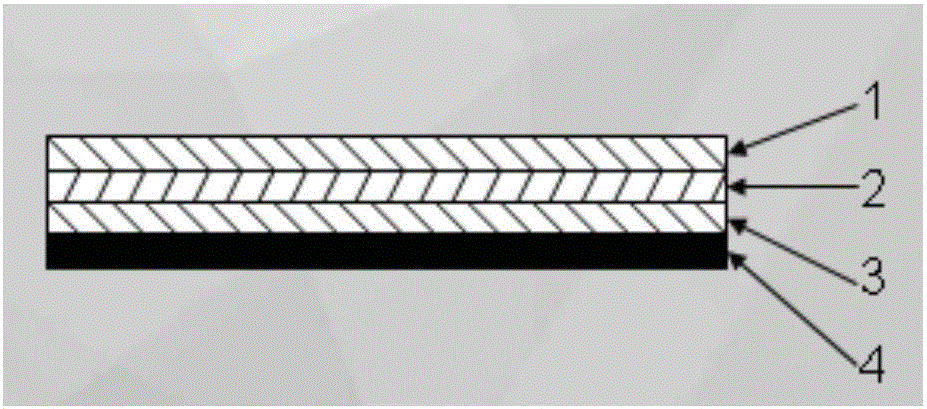

[0044] A thermal paper with high water resistance, including a base paper layer, a primer layer, a thermal layer, and a protective layer;

[0045] The base coat is: 100 parts of filler, 15 parts of adhesive, 50 parts of plastic pigment;

[0046] Heat-sensitive layer: 100 parts of filler, 150 parts of color developer dispersion, 100 parts of sensitizer dispersion, 25 parts of new adhesive, 50 parts of crosslinking agent, 20 parts of lubricant, 30 parts of dye dispersion;

[0047] Protective layer: 100 parts of filler, 100 parts of adhesive, 30 parts of cross-linking agent.

[0048] The new adhesive in the heat-sensitive layer is modified polyvinyl alcohol.

[0049] The grinding conditions for the color developer dispersion of the thermal layer are: 40 parts of color developer and 3 parts of polyvinyl alcohol, mixed to prepare a color developer dispersion with a concentration of 40% to 50%, and grind to 0.3 to 0.3 in a wet grinder. 1.5 microns;

[0050] The grinding cond...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap