A vibration isolator zero adjustment method and inspection device

A technology of inspection device and vibration isolator, applied in the direction of measuring device, instrument, measuring angle, etc., to avoid the effect of pointing angle deviation exceeding the standard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

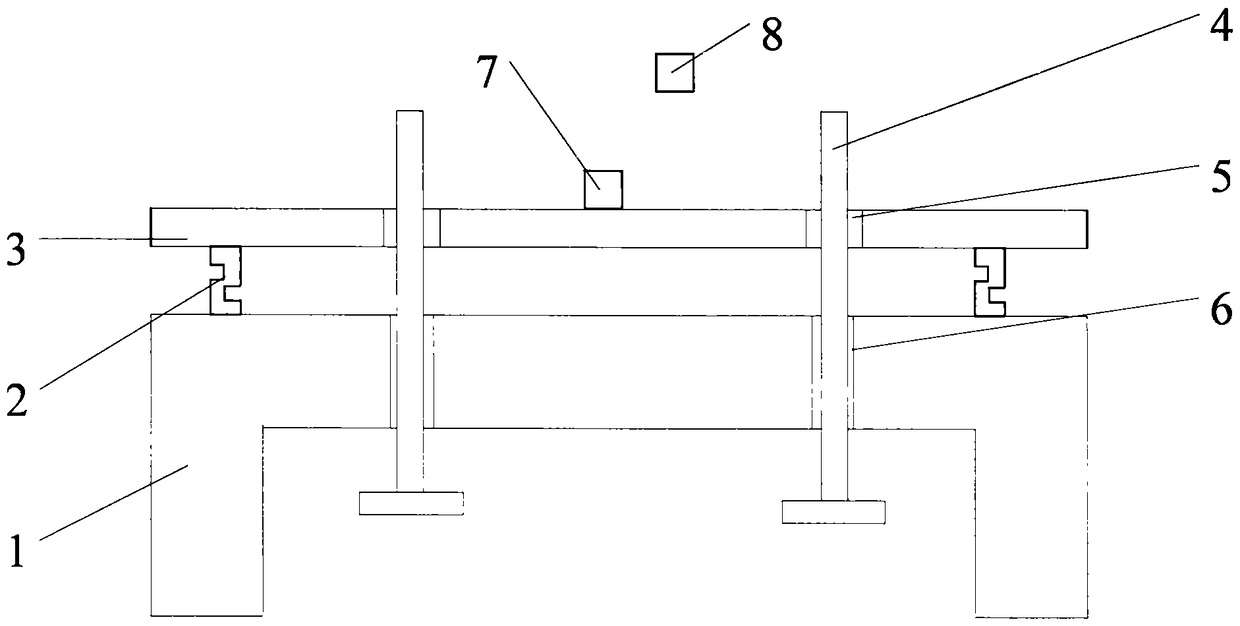

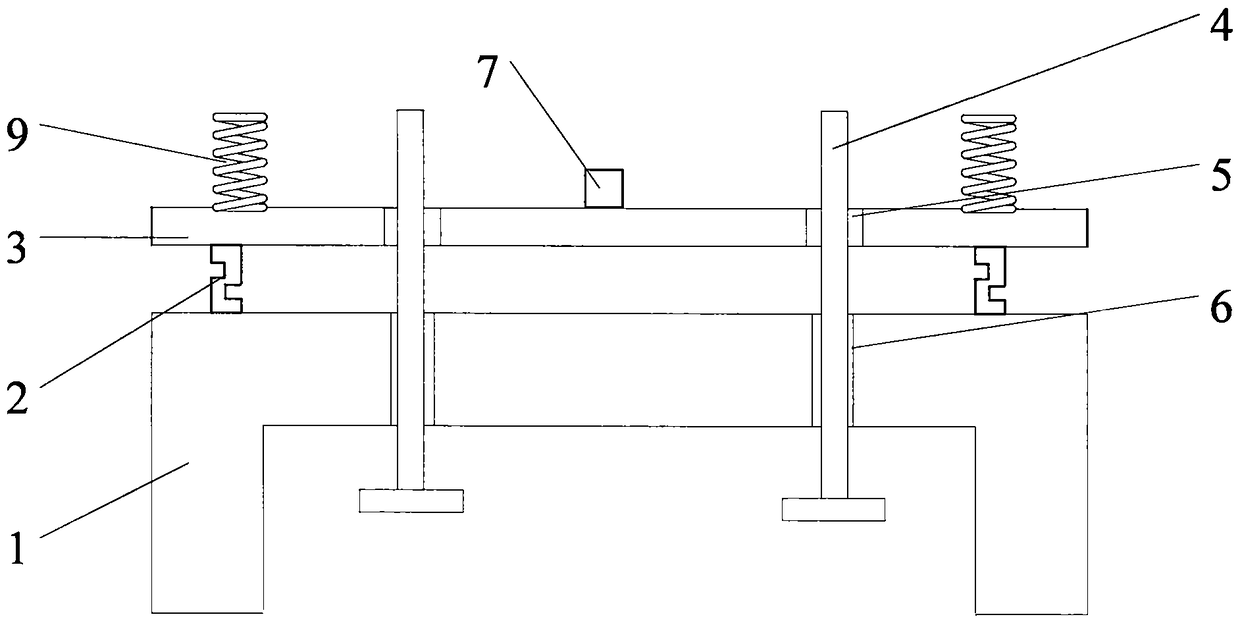

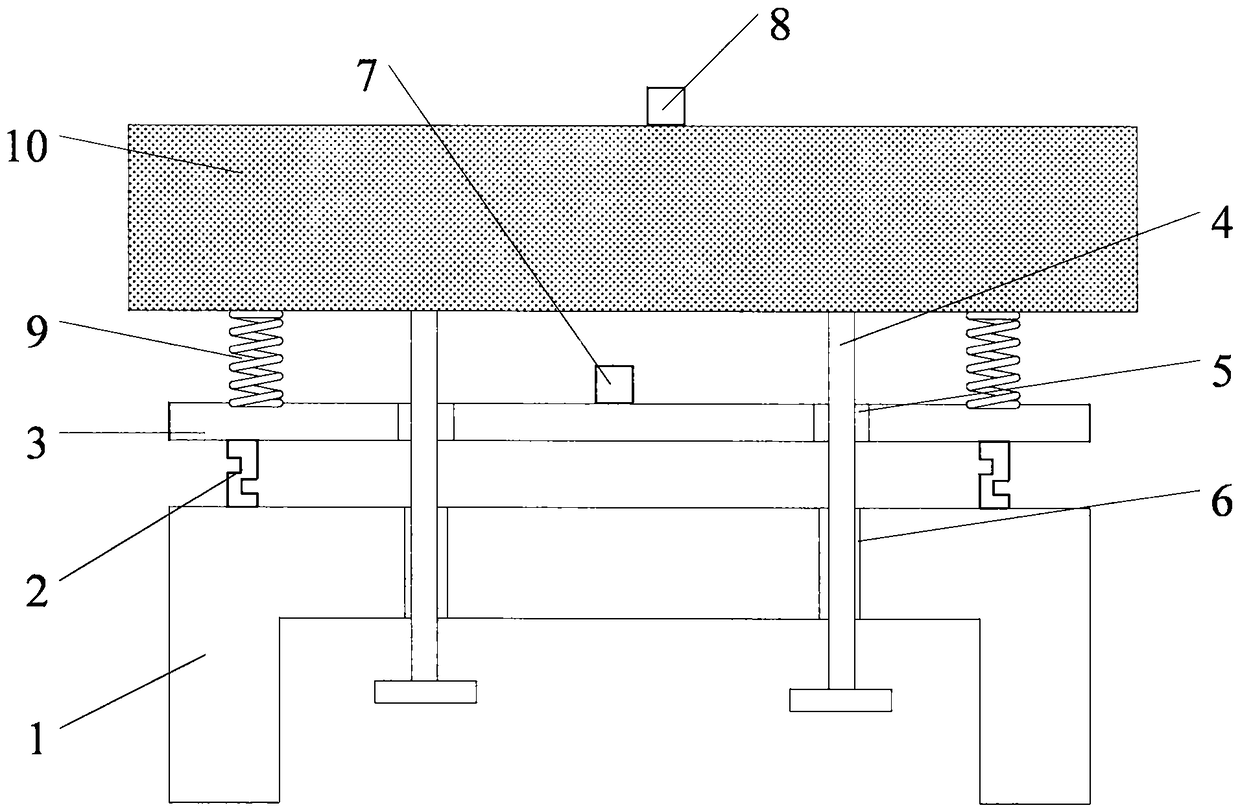

[0015] It should be understood that the vibration isolator zero adjustment method of the present invention can use the angle α between the vibration isolator precision measurement mirror and the reference precision measurement mirror in the gravity state, the vibration isolator precision measurement mirror and the reference precision measurement mirror in the gravity unloaded state. The angle β between the measuring mirrors and the theoretical value γ of the vibration isolator installation are used to obtain the commissioning value of the installation angle of the vibration isolator. The zero position commissioning method of the vibration isolator is realized by the zero position inspection device of the vibration isolator. The zero position inspection device of the vibration isolator is composed of a base, a force sensor, a test table, a self-locking screw, a via hole, a screw nut, a precise measuring mirror on the table and a fine measuring mirror of the vibration-isolated bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com