Automatic grinding method and device for tablet of music box

A sound chip and grinding technology, applied in the direction of grinding automatic control device, grinding frame, grinding bed, etc., can solve the problems of high labor intensity, large safety hazards, fixed electrolysis head, etc., and achieve improvement The effect of grinding precision, accurate adjustment and flexible adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

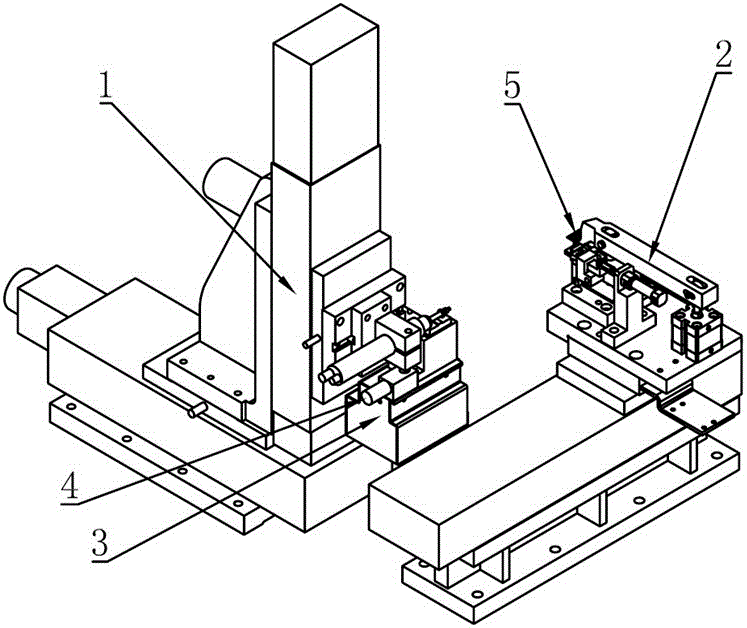

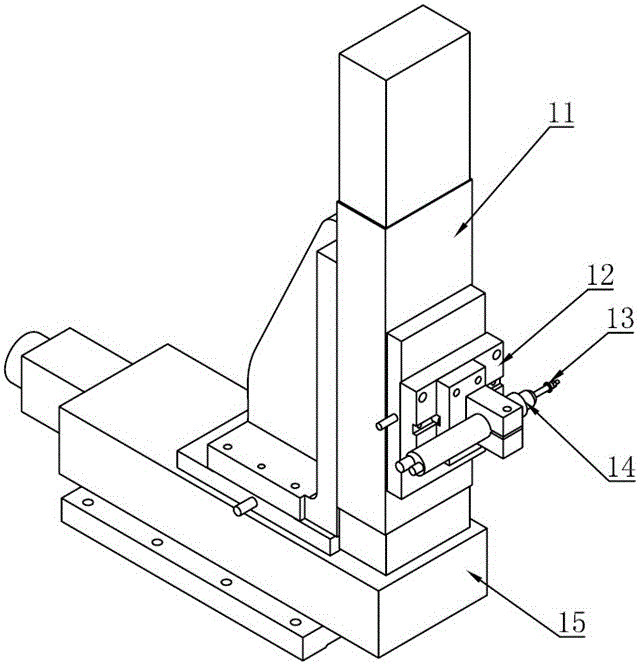

[0022] The present invention will be further described below in conjunction with accompanying drawings and embodiments.

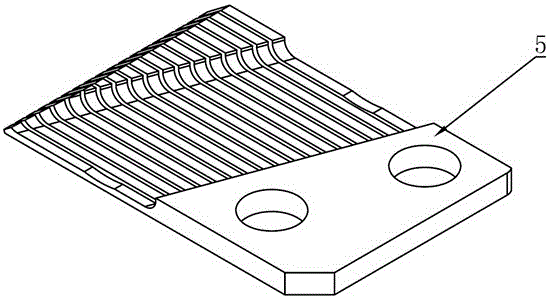

[0023] The structure of an octave sound piece is as follows figure 1 As shown, the head of sheet-like sound sheet 5 has multiple sound keys side by side. In order to adjust the frequency of the sound sheet's vibration, it is necessary to process the sound keys at the head of the sound sheet. The automatic grinding octave sound sheet method adopts the following steps:

[0024] Step 1, input the grinding amount of the sound piece into the controller, and input the control parameters of the grinding mechanism into the controller.

[0025] Step 2, the controller drives the grinding wheel driven by the grinding mechanism to approach the part of the sound piece that needs to be ground.

[0026] Step 3, using the sonar sensor connected to the controller to detect and determine whether the sound piece is in contact with the grinding wheel; if the sound piece is no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com