Pressure self-adaptive briquetting machine

A self-adaptive, ball-pressing technology, which is applied in the direction of presses, material forming presses, manufacturing tools, etc., can solve the problems of large pressing force, mechanical loss, and low pressing efficiency, so as to solve the problem of damage and prevent blockage The effect of material jam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0014] The specific embodiments are described below with reference to the drawings.

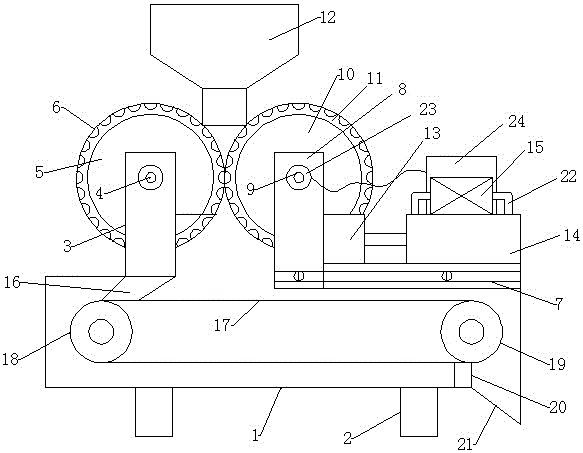

[0015] Such as figure 1 As shown, a pressure adaptive ball pressing machine includes a transmission frame 1, a pillar 2, a left column 3, a driving shaft 4, a driving wheel 5, a left wheel surface 6, a sliding track 7, a right column 8, a driven shaft 9, The driven wheel 10, the right wheel surface 11, the lower hopper 12, the connecting block 13, the pushing cylinder 14, the control hydraulic pump 15, the feeding baffle 16, the conveyor belt 17, the driving wheel 18, the driven wheel 19, and the discharging stop 20 , Discharge port 21, oil pipe 22, pressure sensor 23, controller 24.

[0016] The transmission frame 1 is welded by channel steel, and three or more pillars 2 are welded under the transmission frame 1. A left upright column 3 is installed on the upper left part of the transmission frame 1 by welding. The upper part of the left upright column 3 is installed with a driving shaft 4 thro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap