A plunger pump power end

A technology of power end and plunger pump, which is applied in the direction of piston pump, pump, pump element, etc., can solve the problem of high noise, hair pulling at the end of the slide hole of the fuselage, affecting the development of high efficiency, energy saving and lightweight of the reciprocating plunger pump. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

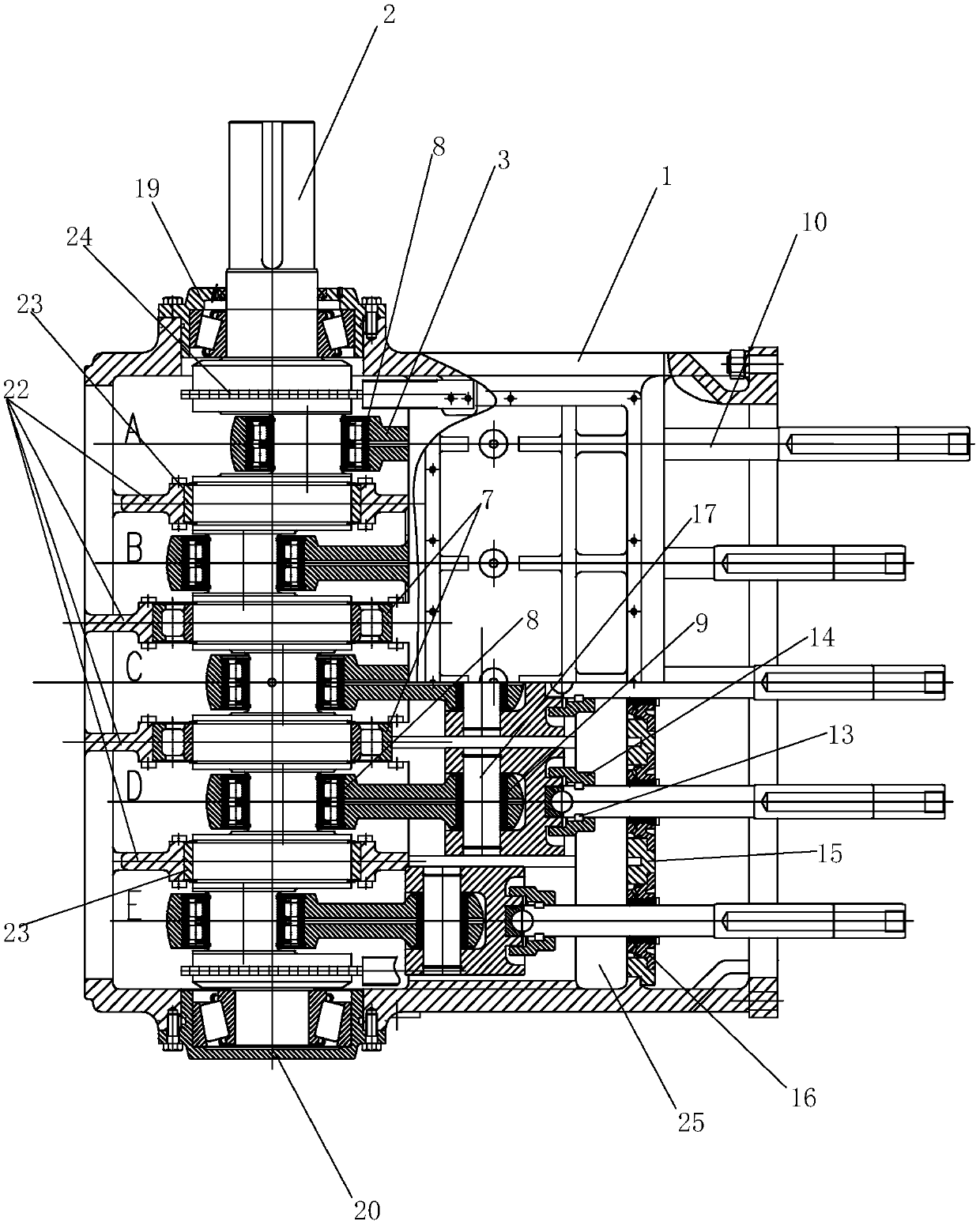

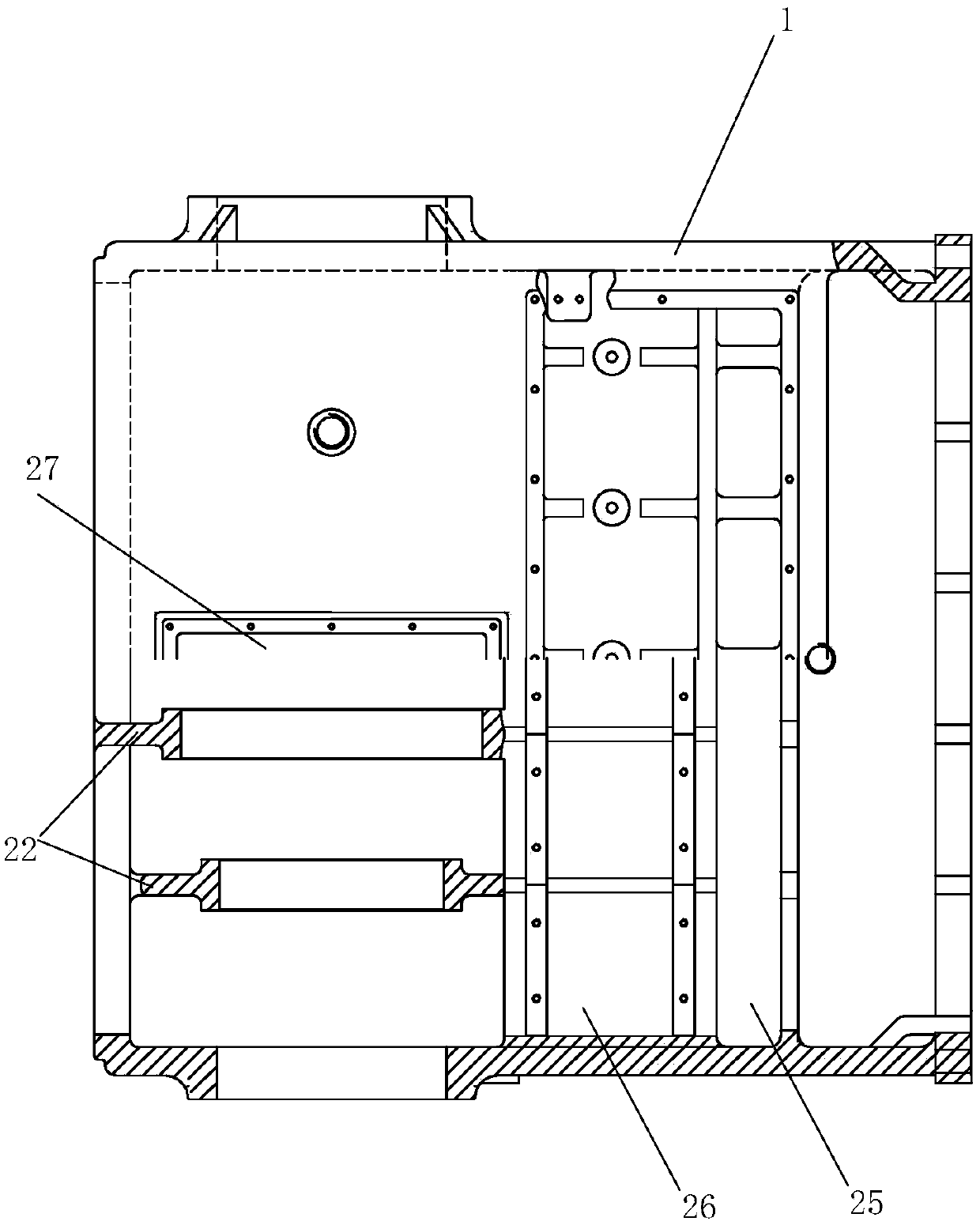

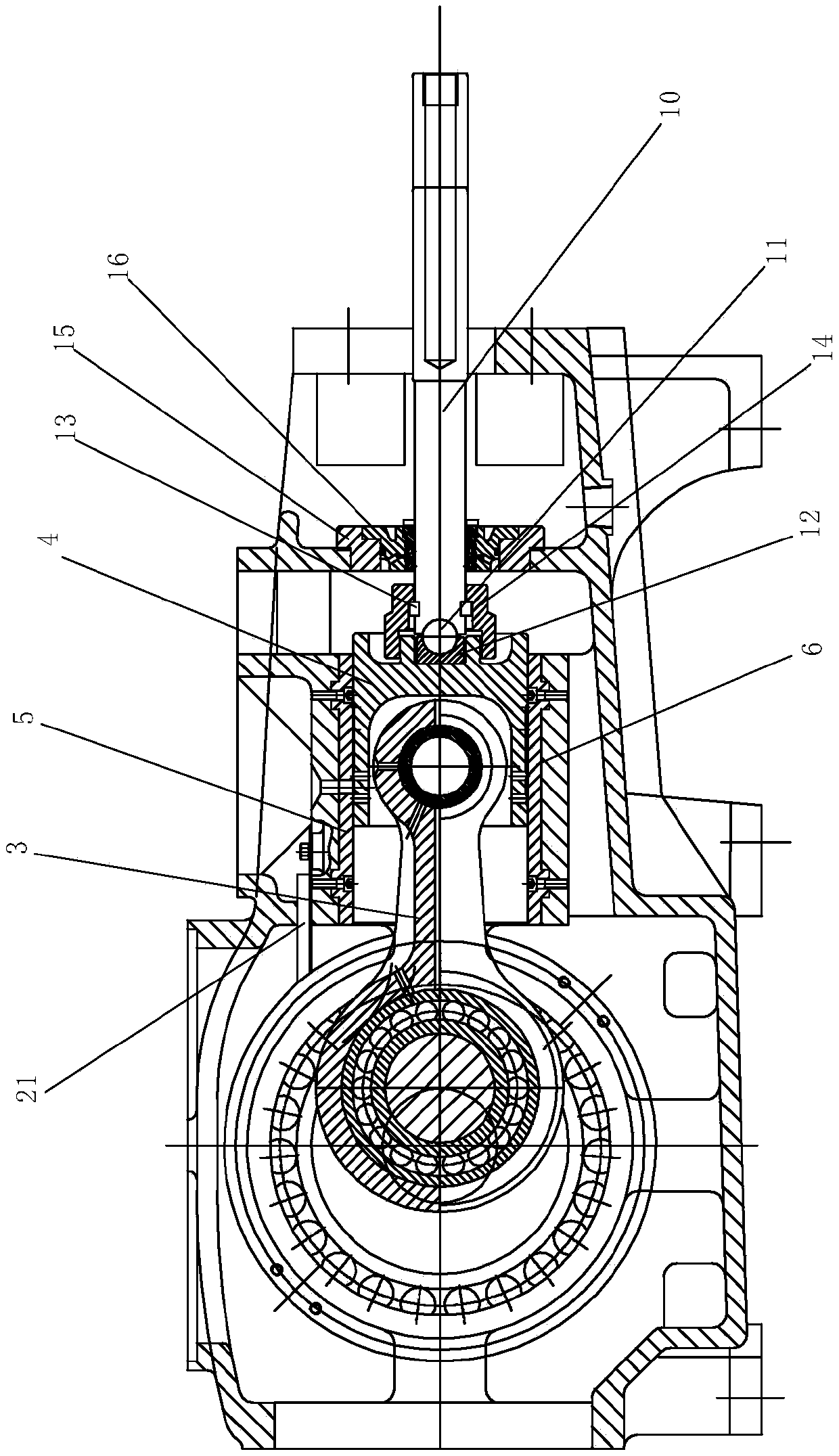

[0021] Such as Figure 1~4 The power end of the plunger pump shown includes a fuselage 1, a crankshaft 2 arranged in the fuselage 1, and N sets of transmission components driven by the crankshaft 2 to radially reciprocate. The N sets of transmission components are respectively connected to the N 10 plungers are connected, wherein N is a natural number; the two ends of the crankshaft 2 and the fuselage are respectively connected by bearings;

[0022] When N=1, there are two fulcrum connection structures between the crankshaft and the fuselage, and the two fulcrum connection structures are respectively: the bearing connection structure between the two ends of the crankshaft and the fuselage;

[0023] When N≥2, there are fixed support plates 22 greater than or equal to 1 and less than or equal to N-1 inside the fuselage, and each fixed support p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com