A quick-change punch mechanism

A technology of punches and fixing mechanisms, which is applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of long maintenance time of punches, easy damage of punch parts, and easy falling off of gaskets, etc., and shorten the required time. time, improve production efficiency, and the gasket is firm and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

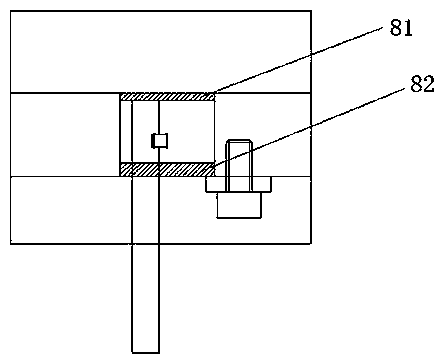

[0029] Example 1: image 3 It is a structural schematic diagram of the punch, the size of the upper gasket is preferably 1.0mm, and the size of the lower gasket is preferably 3.0mm; Embodiment 2: Figure 4 It is a structural schematic diagram of the punch, the size of the upper gasket is preferably 1.2mm, and the size of the lower gasket is preferably 2.8mm; Embodiment 3: Figure 5 It is a structural schematic diagram of the punch, the size of the upper gasket is preferably 1.4mm, and the size of the lower gasket is preferably 2.6mm; Embodiment 4: Image 6 It is a schematic diagram of the structure of the punch, the size of the upper gasket is preferably 3.0mm, and the size of the lower gasket is preferably 1.0mm;

[0030] The following table is the gasket adjustment corresponding table of this technical solution:

[0031]

[0032] Figure 7 It is a schematic structural diagram of the punch and the upper gasket. It can be seen from the figure that there is a punch hole on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com