A Simulation Method of Special Oil-Water Emulsion Layer in Crude Oil Emulsion

An oil-water emulsification and emulsion technology, applied in chemical instruments and methods, mixing methods, chemical/physical processes, etc., to achieve the effect of flexible adjustment and simple and reliable simulation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

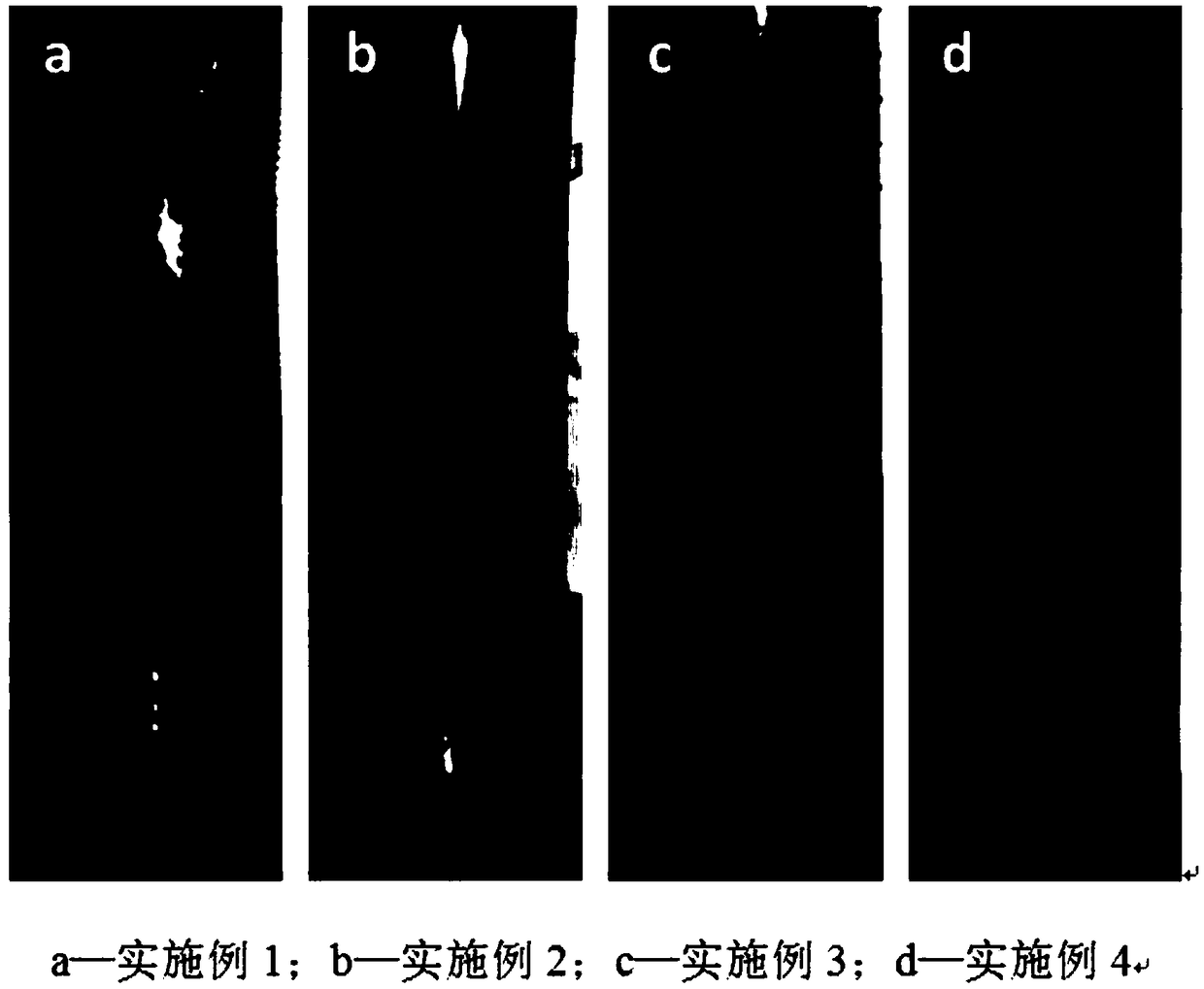

Image

Examples

Embodiment 1

[0033] (1) Heat the crude oil from oilfield A in a water bath at 45°C, take 10 mL of crude oil, add 300 mL of n-pentane to dilute, stir at a stirring rate of 200 rpm for 20 min, let it stand for 12 h, and then spin it in a centrifuge for 10 min to separate asphaltenes Add 100mL of acetone to the filtered n-pentane filtrate, stir for 15min at a stirring rate of 200rpm, let stand for 12h and then spin with a centrifuge for 15min to separate the colloidal component.

[0034] (2) Take 3mL of crude oil from oilfield A, 1mL of asphaltene component and 1mL of colloidal component, add it to 100mL of toluene, stir at a stirring rate of 500rpm for 40min, and obtain a toluene mixed solution.

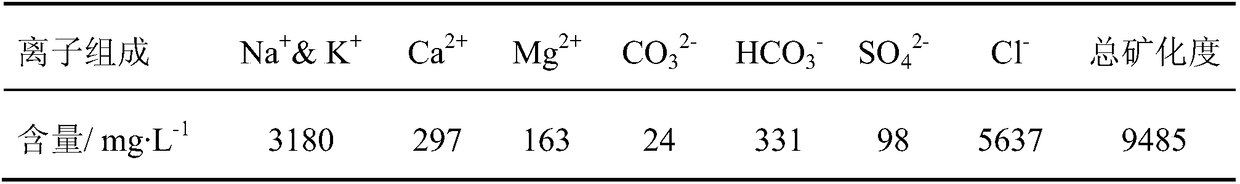

[0035] (3) According to the ionic composition of mineralized water in oilfield A (see Table 1), 5L of oilfield simulated mineralized water was prepared, 2g of hydrophobic association polyacrylamide was added, and heated in a water bath at 50°C to obtain a mass concentration of 400mg / L of polymer s...

Embodiment 2

[0038] (1) Heat the crude oil from oilfield A in a water bath at 45°C, take 10 mL of crude oil, add 500 mL of n-pentane to dilute, stir at a stirring rate of 300 rpm for 10 min, let stand for 12 h, and then spin in a centrifuge for 6 min to separate asphaltenes Add 100mL of acetone to the filtered n-pentane filtrate, stir for 10min at a stirring rate of 300rpm, let stand for 12h and then spin with a centrifuge for 10min to separate the colloidal components.

[0039](2) Take 3mL of crude oil from oilfield A, 2mL of asphaltene component and 1mL of colloidal component, add it to 200mL of toluene, stir at a stirring rate of 800rpm for 30min, and obtain a toluene mixed solution.

[0040] (3) According to the ionic composition of mineralized water in oilfield A (see Table 1), 5L of oilfield simulated mineralized water was prepared, 1g of hydrophobic association polyacrylamide was added, and heated in a water bath at 50°C to obtain a mass concentration of 200mg / L of polymer solution...

Embodiment 3

[0043] (1) Heat the crude oil from oil field B in a water bath at 60°C, take 10 mL of crude oil, add 300 mL of n-pentane for dilution, stir at a stirring rate of 400 rpm for 20 min, let it stand for 16 h, and then spin it in a centrifuge for 15 min to separate asphaltenes Add 100mL of acetone to the filtered n-pentane filtrate, stir for 25min at a stirring rate of 400rpm, let stand for 12h and then spin with a centrifuge for 10min to separate the colloidal components.

[0044] (2) Take 3mL of crude oil from oilfield B, 1mL of asphaltene component and 1mL of colloidal component, add it to 100mL of toluene, stir at a stirring rate of 400rpm for 60min, and obtain a toluene mixed solution.

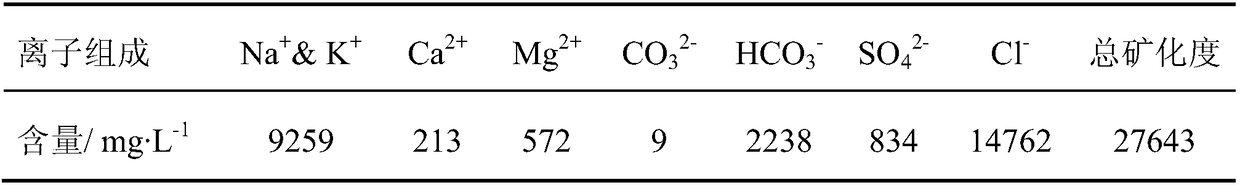

[0045] (3) According to the ion composition of mineralized water in oilfield B (see Table 2), 5L of oilfield simulated mineralized water was prepared, 2g of high molecular weight linear polyacrylamide was added, and heated in a water bath at 65°C to obtain a mass concentration of 400mg / L poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com