Circular stirrup cutting-aligning welding machine for modern fabricated architectural engineering reinforcement cage

A technology for construction engineering and reinforcement cages, which is applied in the field of cutting and alignment welding machines for round stirrups of reinforcement cages in modern prefabricated construction engineering, can solve the problems of low work efficiency, high labor intensity, and low efficiency, so as to improve processing efficiency, The effect of high degree of mechanization and reduction of labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

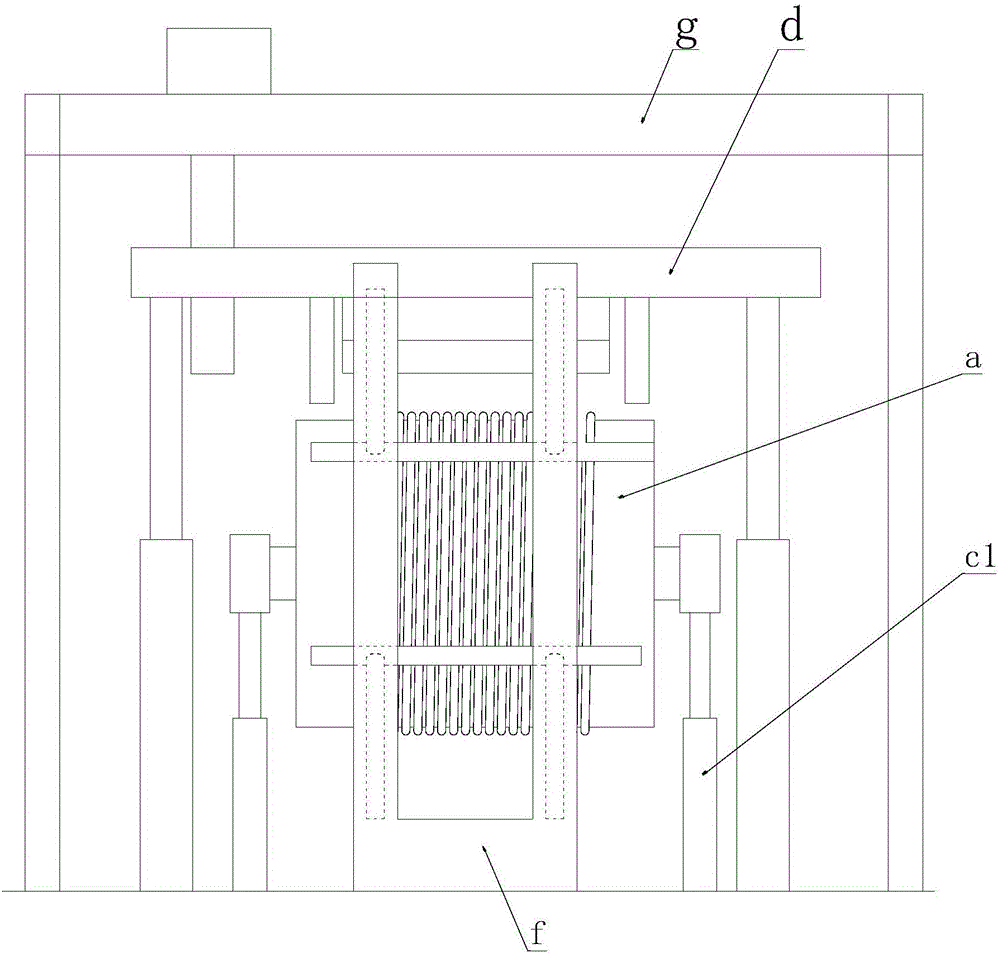

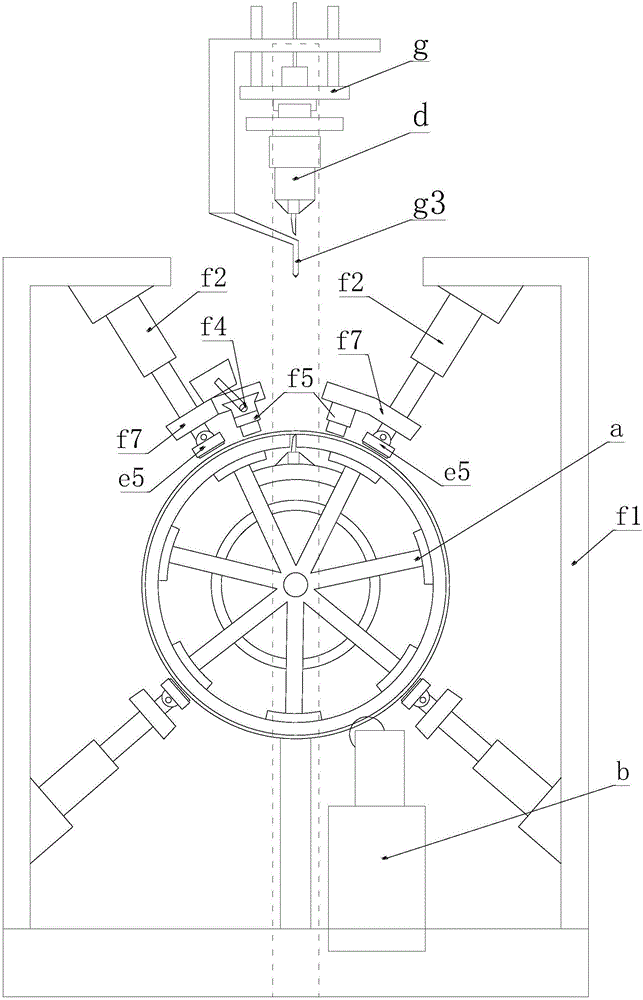

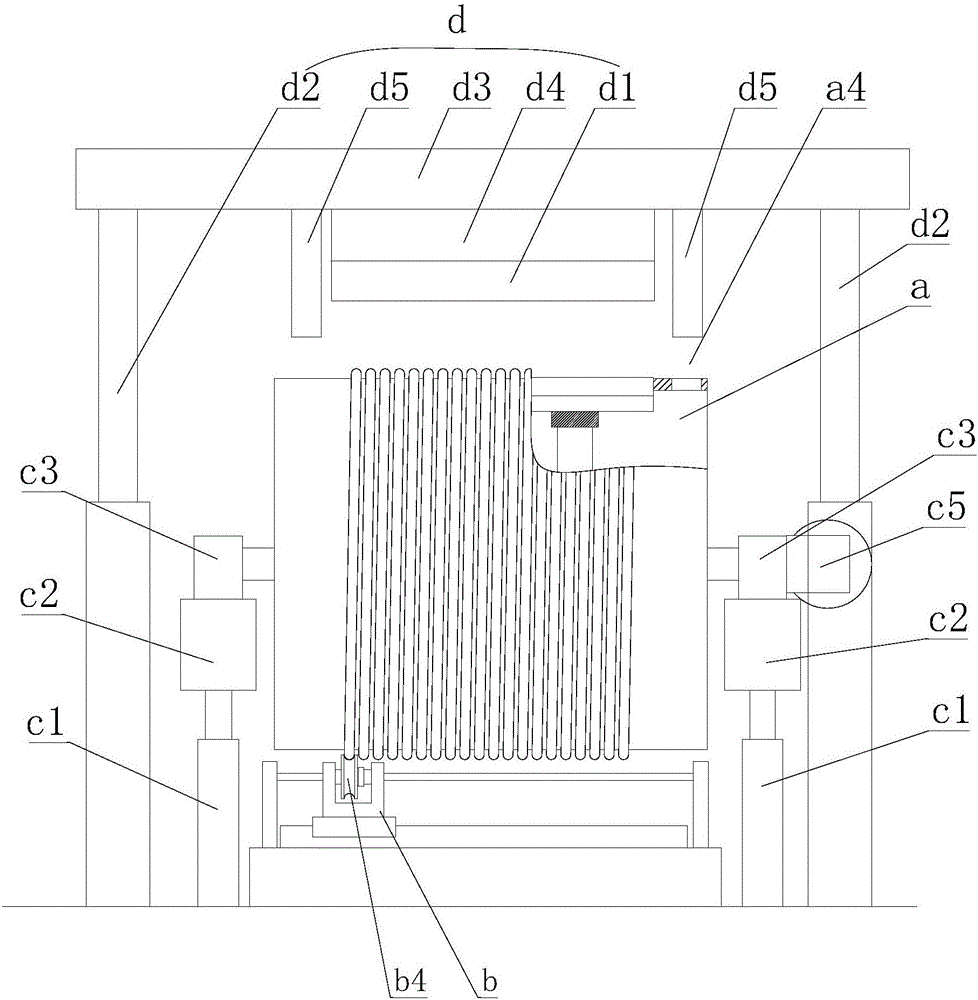

[0052] Such as Figure 1 to Figure 20 As shown in the figure, a cutting and aligning welding machine for round stirrups of a modern fabricated building engineering reinforcement cage includes a base on which a spiral reinforcement winding assembly a is provided, corresponding to the spiral reinforcement winding assembly a Spiral winding synchronizer b, outer cutting component d, stirrup clamping component f and end welding component g.

[0053] The spiral tendon winding assembly a includes two winding supports c1 facing each other. A winding tube is installed between the two winding supports c1. The winding tube includes a cylinder body a1. A cylinder rotating shaft a5 is pierced inside the a1, and the two ends of the cylinder rotating shaft a5 are respectively movably connected with the two winding supports c1;

[0054] The two ends close to the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com