Power Rotary Eccentric Tool Holder and Power Head Device

A technology of power rotation and tool seat, which is applied in the direction of driving devices, positioning devices, manufacturing tools, etc., can solve problems such as low efficiency, achieve great interchangeability, and reduce equipment investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

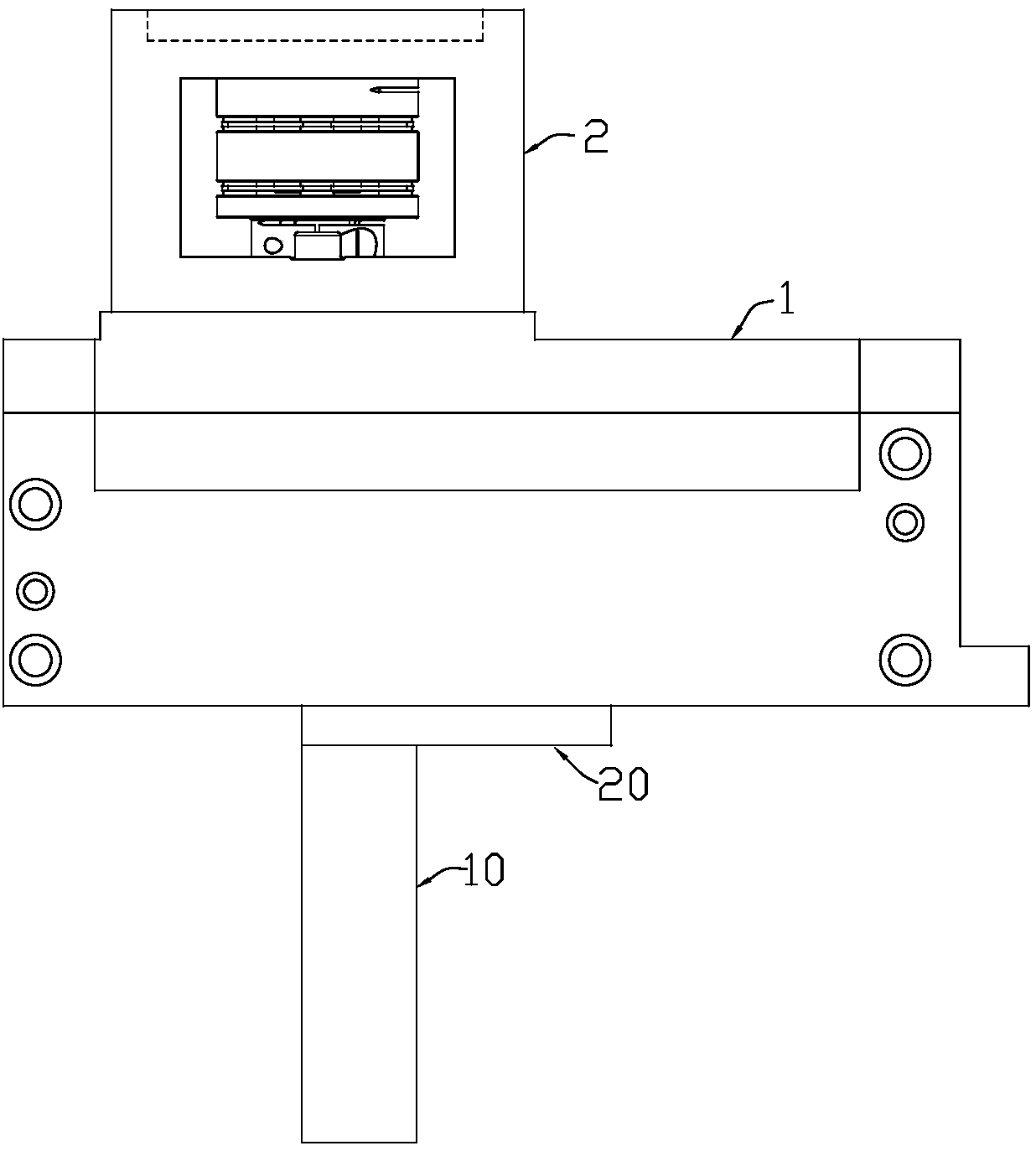

[0021] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

[0022] Such as figure 1 As shown, the power rotating eccentric tool seat of an embodiment of the present invention can be used for U-shaped bone nail processing, and it includes a seat body 10, a rotating disc 20 mounted on the seat body 10 rotatably relative to the seat body 10, and a rotating disk 20 installed on the seat body The transmission assembly 30 on 10, at least one ER chuck assembly 40 installed on the base 10. The transmission assembly 30 and the rotating disc 20 are located on the same end face of the base body 10 , and the ER chuck assembly 40 is located on the side surface of the base body 10 and is in transmission connection with the transmission assembly 30 .

[0023] The entire power rotating eccentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com