Nutritional agent for tobacco planting

A nutrient and tobacco leaf technology, which is applied in the field of tobacco leaf planting nutrient, can solve the problems of organic matter content decline, chemical fertilizer soil acidification, soil fertility reduction, etc., and achieve the effect of facilitating absorption, solving waste residue pollution, and increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The nutrient agent for planting tobacco leaves is obtained by the following preparation method:

[0026] ①Cleaning: Wash the discarded oyster shells with clean water to remove the silt and impurities on the surface of the oyster shells;

[0027] 2. drying: drying the oyster shells obtained in step 1, and pulverizing them with a ball mill to obtain 80 mesh oyster shell coarse powder;

[0028] ③Low temperature pulverization: The oyster shell coarse powder obtained in step ② is subjected to low temperature freezing at 0°C and low temperature sublimation drying in sequence, and then the liquid nitrogen is used as the grinding medium, and the ultra-low temperature pulverizer is used for low temperature pulverization at -80°C;

[0029] ④High-pressure micro-jet ultra-fine pulverization treatment, add the material obtained in step ③ to 5 times the weight of pure water and mix evenly, treat it with a high-speed shear emulsifier for 10 minutes, and then use high-pressure micro-je...

Embodiment 2

[0031] The nutrient agent for planting tobacco leaves is obtained by the following preparation method:

[0032] ①Cleaning: Wash the discarded oyster shells with clean water to remove the silt and impurities on the surface of the oyster shells;

[0033] 2. drying: drying the oyster shells obtained in step 1 and pulverizing them with a ball mill to obtain 100 mesh oyster shell coarse powder;

[0034] ③Low temperature pulverization: The coarse oyster shell powder obtained in step ② is subjected to low-temperature freezing at -10°C and low-temperature sublimation drying in sequence, and then liquid nitrogen is used as the grinding medium, and low-temperature pulverization is carried out at -100°C with an ultra-low temperature pulverizer;

[0035] ④High-pressure micro-jet ultra-fine pulverization treatment, add 6 times the weight of pure water to the material obtained in step ③ and mix evenly, treat it with a high-speed shear emulsifier for 5 minutes, and then use high-pressure mic...

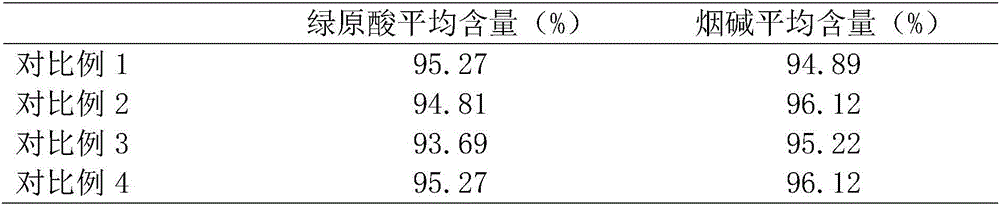

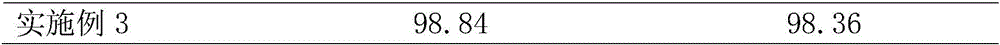

Embodiment 3

[0037] The nutrient agent for planting tobacco leaves is obtained by the following preparation method:

[0038] ①Cleaning: Wash the discarded oyster shells with clean water to remove the silt and impurities on the surface of the oyster shells;

[0039] 2. drying: drying the oyster shells obtained in step 1 and pulverizing them with a ball mill to obtain 100 mesh oyster shell coarse powder;

[0040] ③Low temperature pulverization: The coarse oyster shell powder obtained in step ② is subjected to low-temperature freezing at -18°C and low-temperature sublimation drying in sequence, and then liquid nitrogen is used as the grinding medium, and low-temperature pulverization is carried out at -120°C with an ultra-low temperature pulverizer;

[0041] ④High-pressure micro-jet ultra-fine pulverization treatment, add the material obtained in step ③ to 5 times the weight of pure water and mix evenly, treat it with a high-speed shear emulsifier for 10 minutes, and then use high-pressure mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com