A kind of method for preparing Vinpocetine

A technology for vinpocetine and vincamine, which is applied in the field of compound preparation, can solve the problems of three wastes treatment, adverse effects of solvent residues, unsuitability for large-scale industrial production, environmental pollution, etc., and achieves good reproducibility of results, easy handling, and high purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

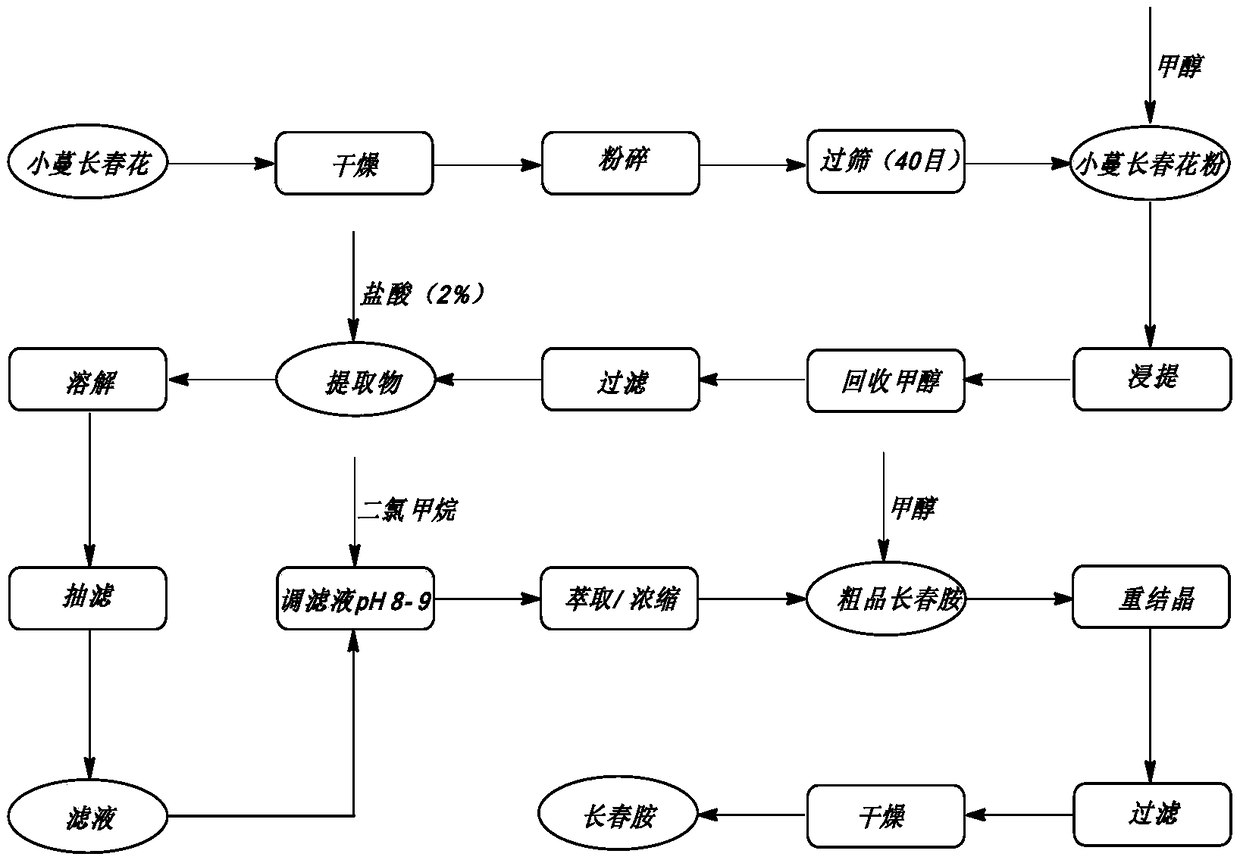

Method used

Image

Examples

Embodiment 1

[0098] This implementation takes vincamine as raw material, first prepares apovincamine, and then prepares vinpocetine with apovincamine as raw material.

[0099] The method that present embodiment prepares Vinpocetine comprises the steps:

[0100] 1) preparation of apovincamine

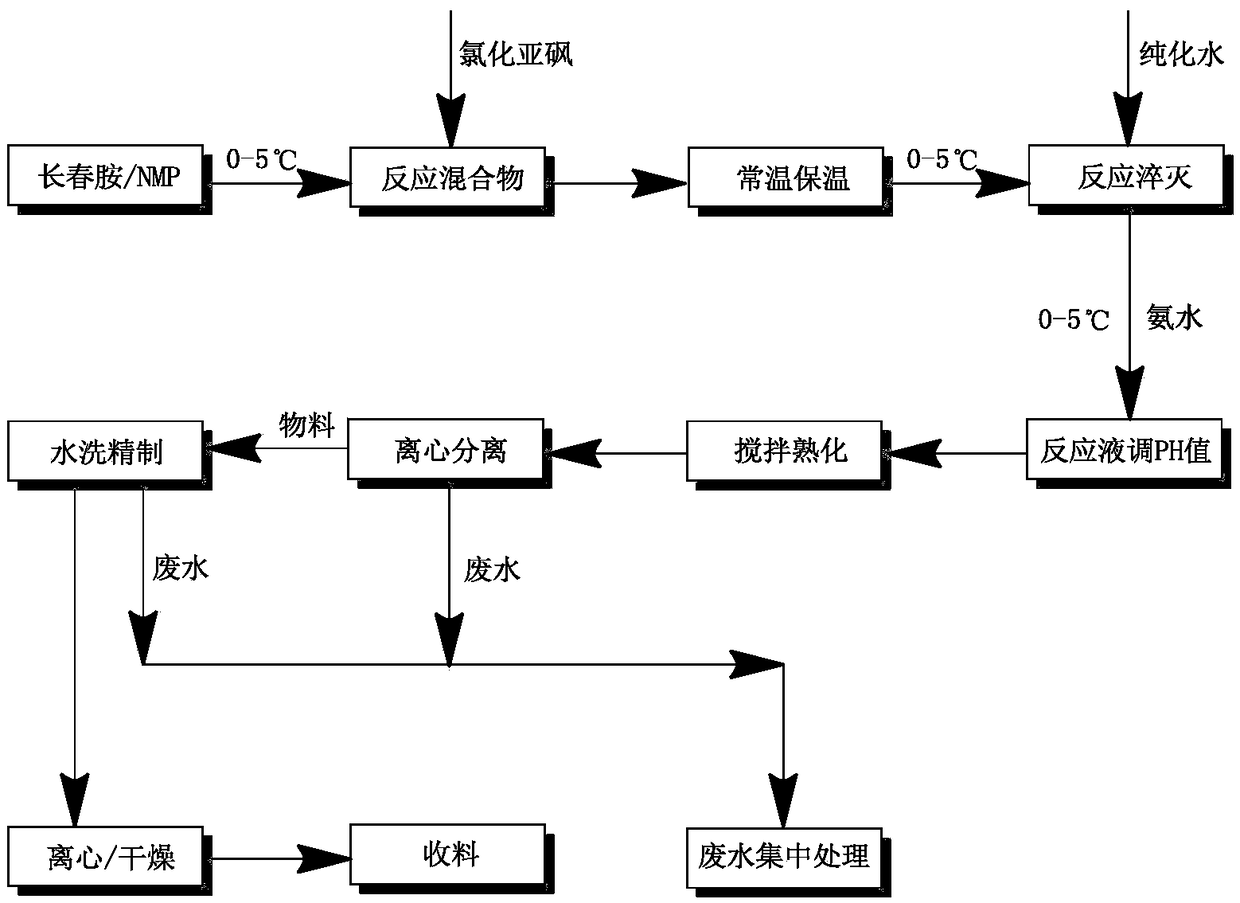

[0101] Put 15mL of NMP and 5g of vincamine into a 50mL dry and clean single-necked flask, stir for 5-10 minutes to obtain a homogeneous mixture, put an external ice-water bath to cool down to 0-5°C, add 1.62mL of thionyl chloride dropwise, and control the internal temperature. When the temperature exceeds 20°C, the dropwise addition is completed in half an hour. The ice bath was removed, and the temperature was raised to normal temperature (RT, 20-25° C.) in about 30 minutes, and the reaction was stirred for 30 minutes. The reaction was monitored by HPLC, and the reaction was terminated when the remaining amount of raw material vincamine was less than 1%. Then lower the temperature to 0-5°C, add 1...

Embodiment 2

[0108] The purity of vincamine in this embodiment is not less than 99.3%.

[0109] This implementation takes vincamine as raw material, first prepares apovincamine, and then prepares vinpocetine with apovincamine as raw material.

[0110] The method that present embodiment prepares Vinpocetine comprises the steps:

[0111] 1) preparation of apovincamine

[0112] Put 690mL of NMP and 230g of vincamine into a 2000mL dry and clean single-necked flask, stir for 5-10 minutes to obtain a uniform mixture, cool down to 0-5°C with an external ice-water bath, add 74.8mL of thionyl chloride dropwise, and control the internal temperature. More than 20 ℃, drop in about 1 hour. Remove the ice bath, stir for about half an hour and heat up to normal temperature (RT, 20-25°C), monitor the remaining amount of vincamine in the reaction with HPLC, end the reaction when the remaining amount is less than 1%, then cool down to 0-5°C, add dropwise Purified water 460mL, control the internal tempera...

Embodiment 3

[0120] The purity of vincamine in this embodiment is not less than 99.3%.

[0121] This implementation takes vincamine as raw material, first prepares apovincamine, and then prepares vinpocetine with apovincamine as raw material.

[0122] The method that present embodiment prepares Vinpocetine comprises the steps:

[0123] 1. Preparation of Apovincamine

[0124] Put 690mL of NMP and 230g of vincamine into a 2000mL dry and clean single-necked flask, stir for 5-10 minutes to obtain a uniform mixture, cool down to 0-5°C with an external ice-water bath, add 74.8mL of thionyl chloride dropwise, and control the internal temperature. More than 20 ℃, drop in about 1 hour. Remove the ice bath, stir for about half an hour and heat up to normal temperature (RT, 20-25°C), monitor the remaining amount of vincamine in the reaction with HPLC, end the reaction when the remaining amount is less than 1%, then cool down to 0-5°C, add dropwise Purified water 460mL, control the internal tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com