A method and device for denitrification and refining of coker wax oil without waste discharge

A technology for coking wax oil and waste discharge, which is applied in the multi-stage series refining process treatment, petroleum industry, hydrocarbon oil treatment, etc. Flexibility, the effect of optimizing raw material and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

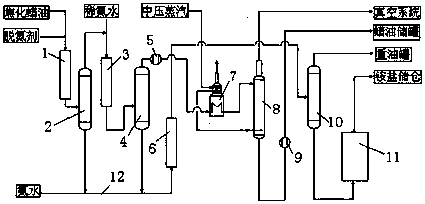

[0017] The present invention has no waste discharge coking wax oil denitrification and refining device, such as figure 1 As shown, including No. 1 static mixer 1, denitrification settling tank 2, No. 2 static mixer 3, No. 3 static mixer 6, ammonia washing settling tank 4, oil-water separation tank 10, concentrated crystallization unit 11, and No. 1 replacement Heater 5, heating furnace 7, No. 2 heat exchanger 9, stripper 8 and settling header 12. The inlet of No. 1 static mixer is respectively connected with the coker wax oil pipeline and denitrification agent tank of the delayed coking unit, and the outlet It is connected with the feed port of the denitrification settling tank. The upper outlet of the denitrification settling tank is connected to the feed port of the ammonia scrubbing settling tank through the No. 2 static mixer, and the dilute ammonia water pipeline is connected to the inlet of the No. 2 static mixer. The lower outlets of the denitrification settling tank a...

Embodiment 2

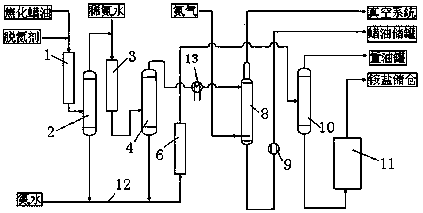

[0022] Another embodiment of the present invention is as figure 2 As shown, the heating device is a steam heater 13, and the top outlet of the ammonia wash settling tank is connected to the feed port of the stripper 3 through the steam heater. Ammonia is used as the stripping agent, and the ammonia pipeline is connected to the stripping agent inlet of the stripping tower. Other processes are the same as in Example 1.

[0023] The coking wax oil is continuously fed at a flow rate of 80.0kg / h, the temperature of the coking wax oil is controlled at 100-120°C, and the denitrification agent is added at a rate of 1.4kg / h. The coker wax oil enters the No. 1 static mixer together with the denitrification agent for mixing reaction, and then enters the denitrification settling tank for sedimentation and separation. The sedimentation residence time is 15 hours. The coker wax oil discharged from the top of the denitrification settling tank enters the No. 2 static mixer together with di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com