A chemical fiber nylon filament fdy electrical control device

An electrical control device, nylon technology, applied in the direction of electrical program control, program control, general control system, etc., can solve the problems of reduced production capacity, waste of labor and property, etc., and achieve the effect of improving efficiency, convenience and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with the embodiment shown in the accompanying drawings, the present invention is described in detail as follows:

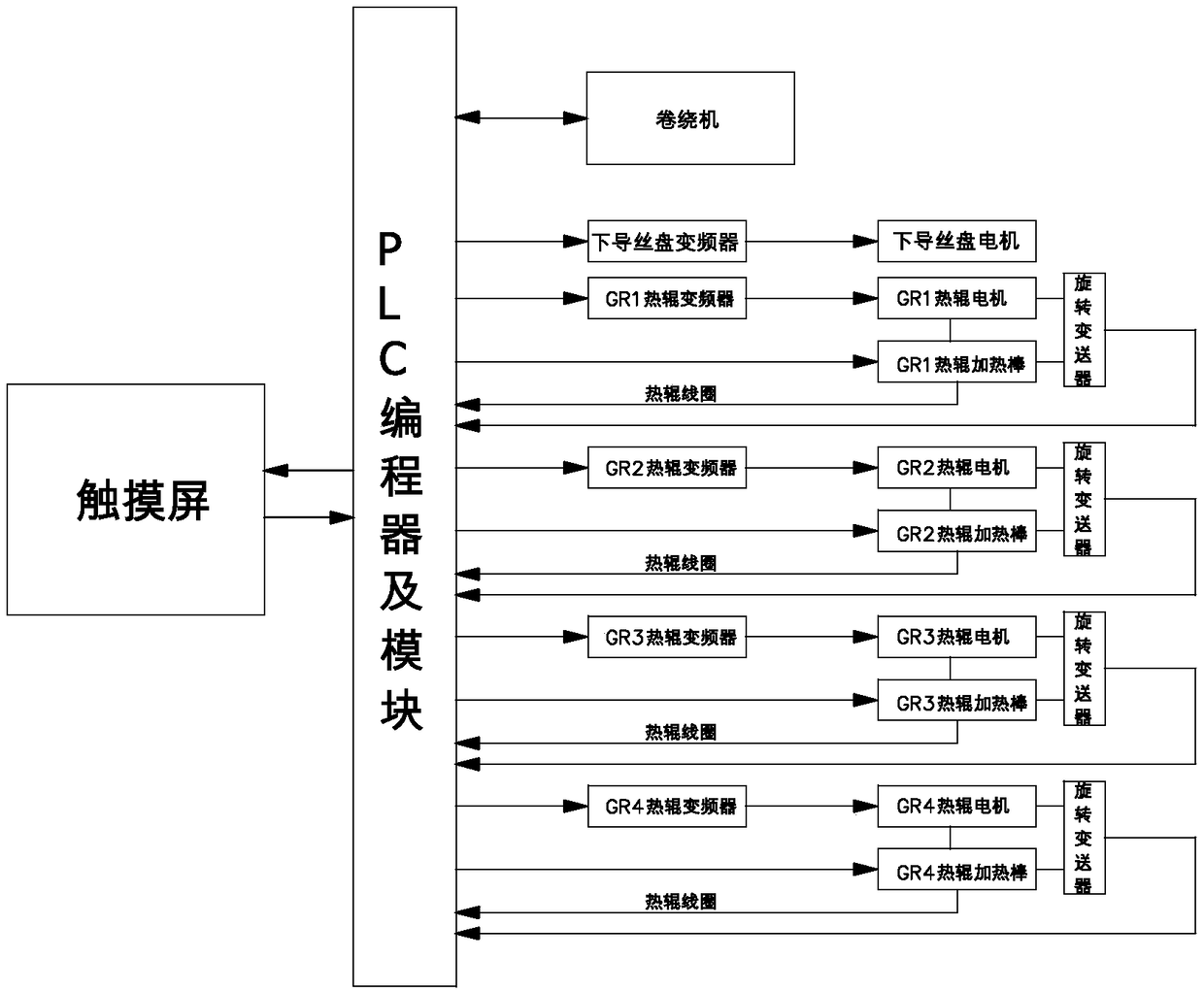

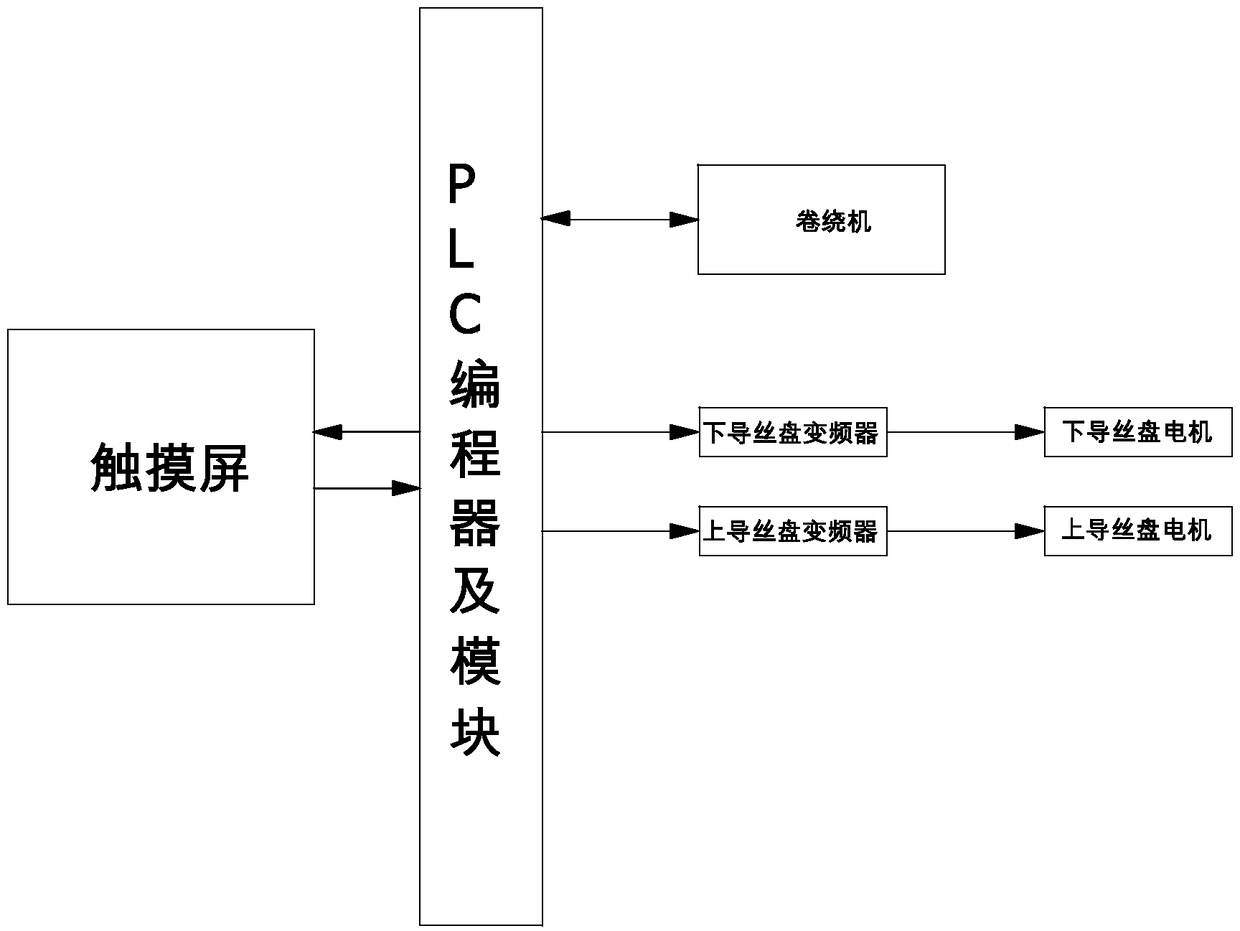

[0016] as attached figure 1 As shown, a chemical fiber nylon filament FDY electrical control device includes a touch screen, a PLC module group connected to the touch screen, a first control path, a first control feedback loop, a second control feedback loop, a third control feedback loop, and a fourth control feedback loop. The control feedback loop and the fifth control feedback loop, the first control path is formed by the PLC module group, the lower godet frequency converter and the lower godet motor; the first control feedback loop is formed between the PLC module group and the winding machine; The second control feedback loop is formed from the PLC module group, GR1 heat roller inverter, GR1 heat roller motor, the first rotary transmitter to the PLC module group; the PLC module group controls the GR1 heat roller heating rod, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com