Lightweight Design Method of High Pressure Heater

A high-pressure heater and lightweight design technology, applied in design optimization/simulation, geometric CAD, special data processing applications, etc., can solve problems such as increased diameter and wall thickness, increased equipment specifications, equipment design and manufacturing difficulties, etc., to achieve The effect of thinning the wall thickness, reducing the wall thickness of parts, and lightweight design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

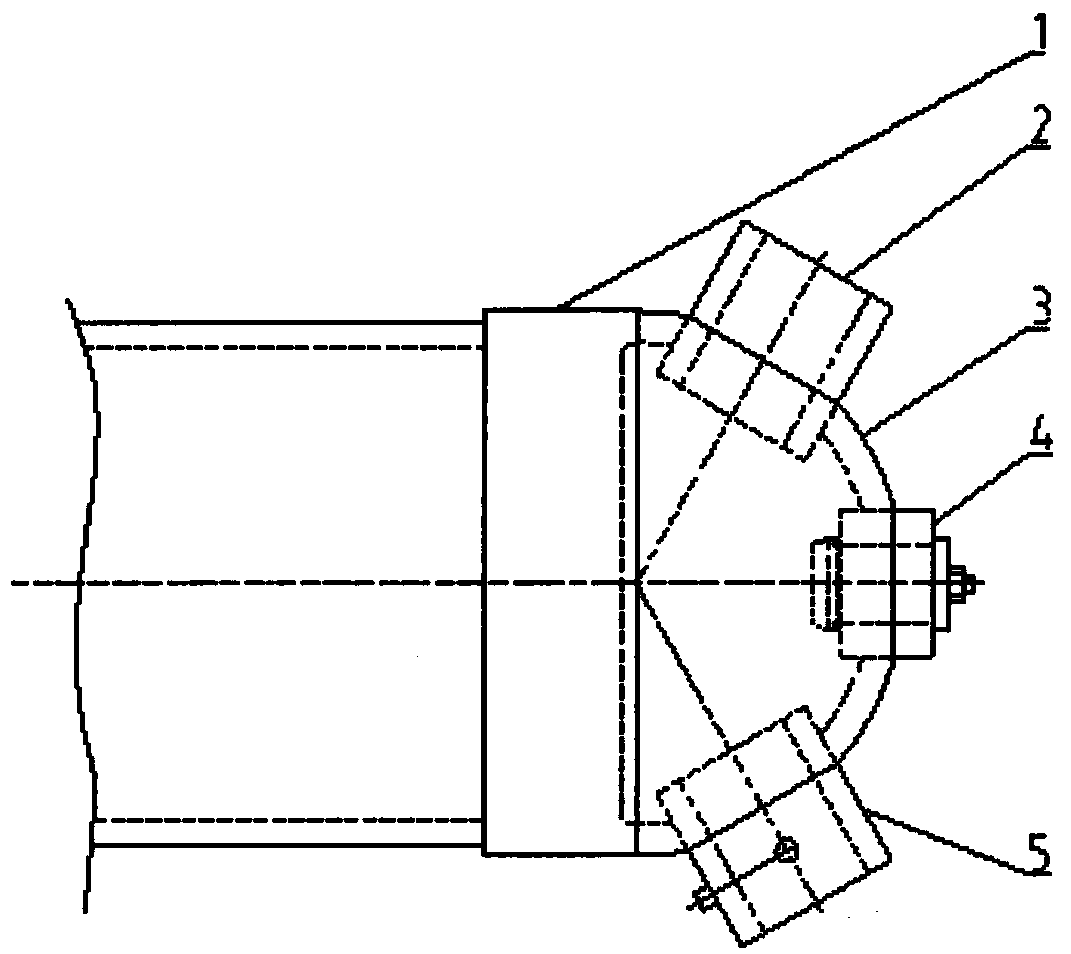

[0025] Such as figure 2 As shown, it is the outline structure diagram of the tube side of the high-pressure heater. Its main pressure-bearing parts include the tube plate 1, the outer side of the tube plate 1 is the water chamber head 3, and the water chamber head 3 is provided with the water outlet pipe 2 and the manhole. 4 and inlet water pipe 5.

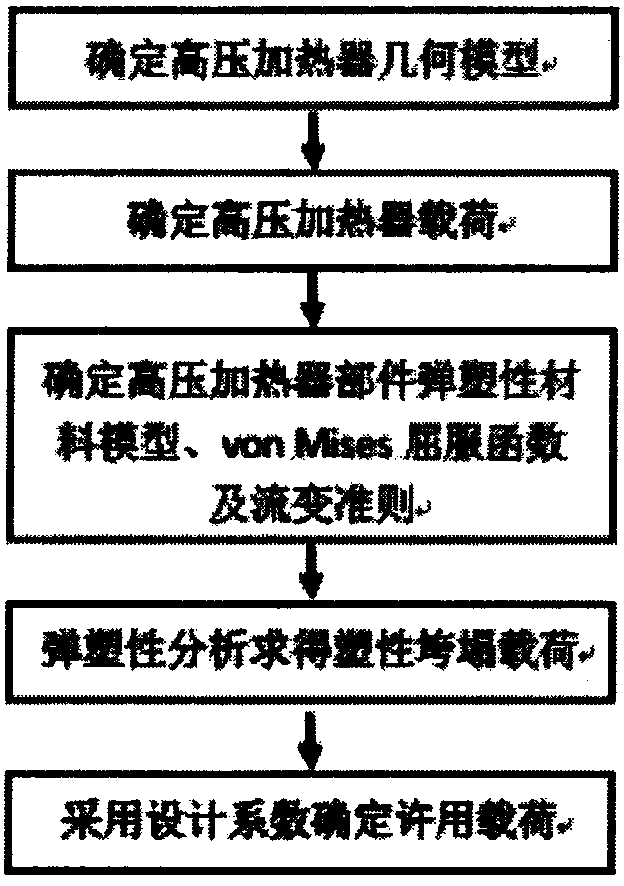

[0026] The design method of the above-mentioned high-pressure heater is as follows:

[0027] The design pressure of a high-pressure heater used in a power plant is 40MPa, and the design temperature is 330°C. The specific steps for the design of high-pressure heaters for power plants based on the direct method based on elastic-plastic analysis are as follows:

[0028] (1) According to figure 2 The geometric model of the high-pressure heater structure used in the typical power plant shown is determined, and the finite element model is established;

[0029] (2) Give the elastic-plastic material constitutive model of each pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com