Mixed coating diaphragm and preparation method and application thereof

A polymer coating and coating technology, which is applied in the direction of hybrid capacitor separators, electrical components, circuits, etc., can solve the problems of insufficient liquid absorption rate and heat resistance of the diaphragm, and achieve simple preparation methods, easy industrialization, Effect of improving specific discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

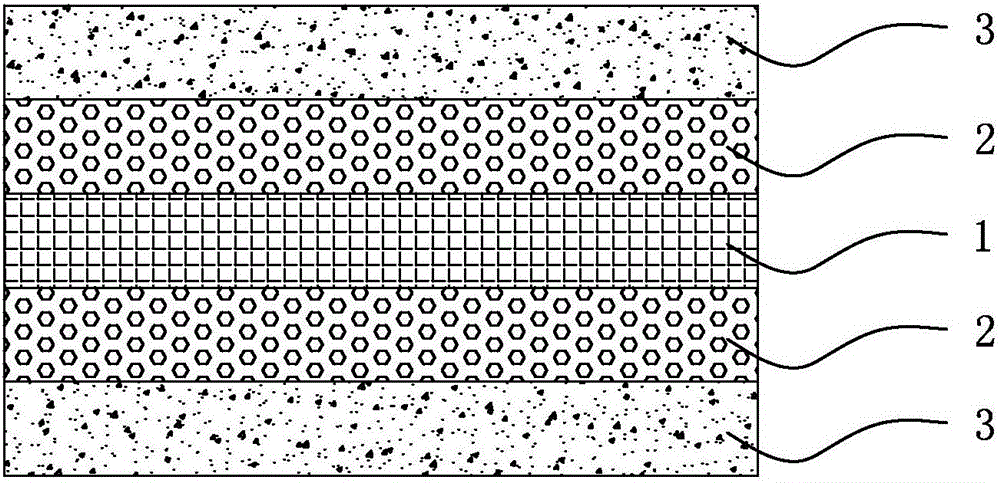

[0040] Weigh 2g of CMC, use 100g of deionized water as the dispersion medium, and stir under vacuum conditions to prepare a dispersion glue. Weigh 15g of 50nm aluminum oxide in the dispersion glue, and vacuum stir to obtain a ceramic slurry. Then, the ceramic slurry is coated on both sides of a 10 μm PP / PE base film by a micro-gravure coating method, and dried to obtain a ceramic particle-coated separator, and the thickness of the single-sided coating of the ceramic particles is controlled at 2 μm.

[0041] Weigh 6g of PVDF in 30g of NMP and stir under vacuum to obtain PVDF glue. Then, PVDF glue is coated on both sides of the above-mentioned ceramic particle-coated diaphragm by dip coating, and dried. The thickness of the single-sided coating of PVDF is 4 μm, and finally cut to form a mixed-coated diaphragm. Mixed coating The structure of the membrane is as figure 1 shown.

Embodiment 2

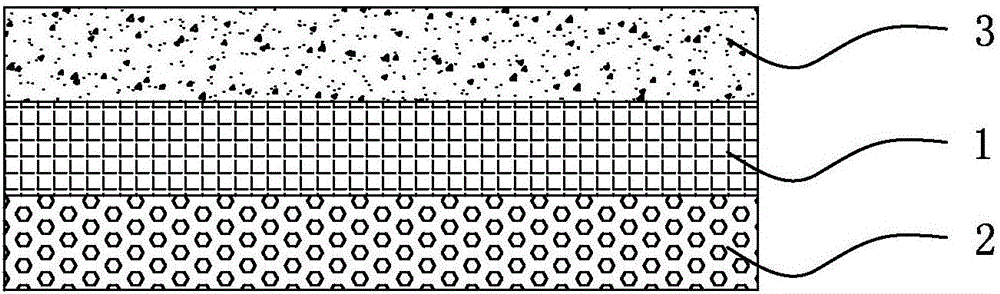

[0043] Weigh 4g of LA133, use 100g of deionized water as the dispersion medium, and stir under vacuum conditions to prepare a dispersion glue. Weigh 20g of 100nm silica into the dispersion glue, and vacuum stir to obtain a ceramic slurry. Then, the ceramic slurry was coated on one side of the 10 μm PP base film by brushing, and dried to obtain a ceramic particle-coated diaphragm, and the coating thickness of the ceramic particle was controlled at 4 μm.

[0044] Weigh 3g of P(VDF-HFP) and 2g of PVDF in 60g of NMP, and stir under vacuum to obtain a mixed glue of PVDF and P(VDF-HFP). Then, the mixed glue is coated on the other side of the ceramic particle coating diaphragm made above by spraying method, and dried. The thickness of the mixed coating of PVDF and P(VDF-HFP) is 4 μm, and finally cut into a mixed Coated separators, hybrid coated separators have a structure such as figure 2 shown.

Embodiment 3

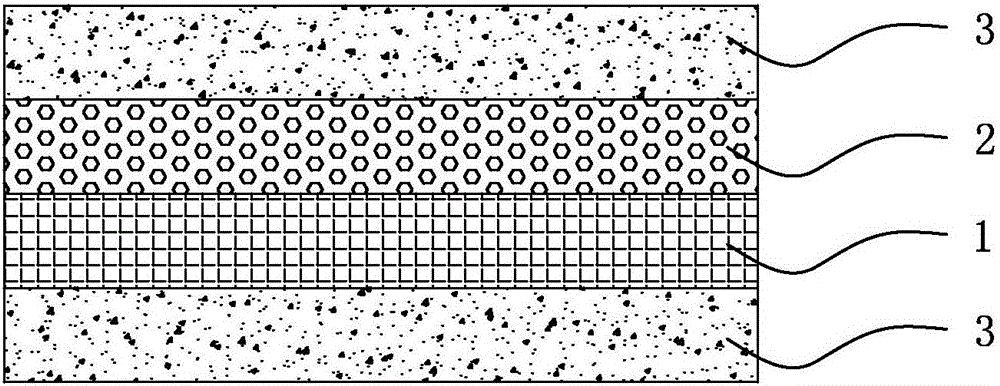

[0046] Weigh 3g of Gelatin, use 10g of deionized water as the dispersion medium, and stir under vacuum conditions to prepare a dispersion glue, weigh 10g of 80nm silicon dioxide and 10g of 50nm titanium dioxide in the dispersion glue, and stir in vacuum to obtain a mixed ceramic slurry. Then, the mixed ceramic slurry is coated on one side of the 20 μm PP / PE / PP base film by brushing method, and dried to obtain a ceramic particle-coated diaphragm, and the coating thickness of the ceramic particle is controlled at 2 μm.

[0047] Weigh 3g of P(VDF-HFP) and 3g of P(VDF-TrFE) in 80g of NMP, and stir under vacuum to obtain a mixed glue of P(VDF-TrFE) and P(VDF-HFP). Then, the mixed glue solution is coated on both sides of the above-mentioned ceramic particle coating diaphragm by spraying method, and dried. The thickness of the single side of the mixed coating of P (VDF-TrFE) and P (VDF-HFP) is 2 μm, and finally divided Cut into a hybrid coated separator, the structure of the hybrid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com