Method for producing conductive coating film, and conductive coating film

A manufacturing method and conductivity technology, applied in the direction of conductive materials dispersed in non-conductive inorganic materials, conductive coatings, equipment for manufacturing conductive/semiconductive layers, etc., can solve insufficient sintering effects, changes in characteristics, and conductivity Problems such as deterioration, to achieve excellent adhesion, prevent the reduction of adhesion force, and improve the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

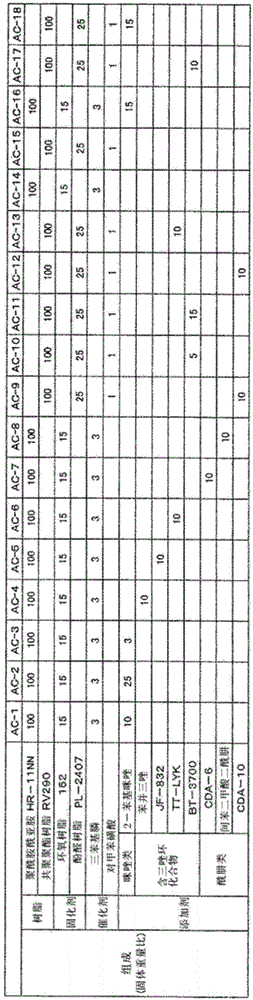

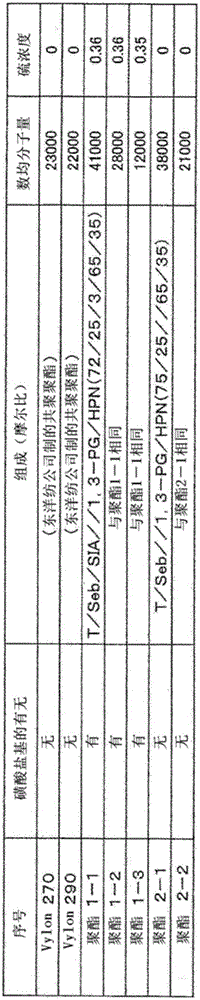

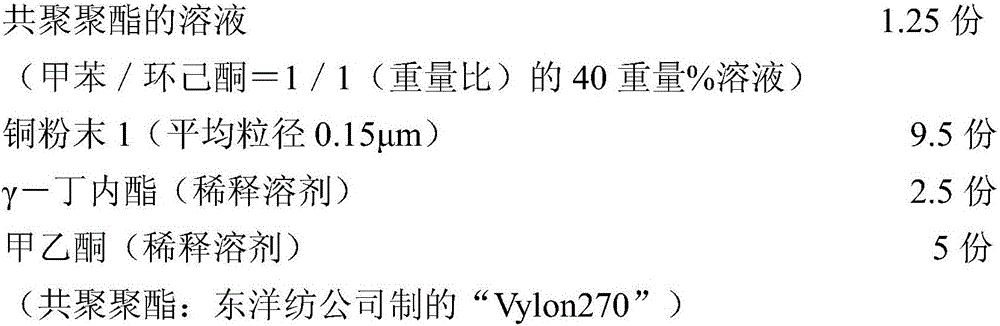

[0100] The composition with the following mixing ratio was put into a sand mill and dispersed at 800 rpm for 1 hour. As the media, zirconia beads with a radius of 0.2 mm were used. Apply the obtained copper paste on the resin layer of the polyimide film (AC-1) with a resin layer using a coater so that the thickness after drying becomes 2 μm, and perform hot air at 100°C for 5 minutes After drying, a coating film containing copper powder was obtained.

[0101] Dispersion composition

[0102]

[0103] The obtained coating film containing copper powder was subjected to superheated steam treatment at 330° C. for 2 minutes. A steam heating device ("DHF Super-Hi10" manufactured by Daiichi High Frequency Industry Co., Ltd.) was used as a generator of superheated steam, and 10 kg / hour of superheated steam was supplied to the heat treatment furnace. Table 3 shows the evaluation results of the obtained conductive coating film.

Embodiment 2~8

[0105] Except having used the polyimide film with the resin layer described in Table 3 as an insulating board|substrate, it carried out similarly to Example 1, and obtained the electroconductive coating film. Table 3 shows the evaluation results of the obtained conductive coating film.

Embodiment 9~14

[0107]The composition with the following mixing ratio was put into a sand mill and dispersed at 800 rpm for 1 hour. As the media, zirconia beads with a radius of 0.2 mm were used. Apply the obtained copper paste on the resin layer of the polyimide film (AC-9) with a resin layer using a coater so that the thickness after drying becomes 2 μm, and perform hot air at 100°C for 5 minutes After drying, a coating film containing copper powder was obtained.

[0108] Dispersion composition

[0109]

[0110] The obtained coating film containing copper powder was subjected to superheated steam treatment at 300° C. for 2 minutes. A steam heating device ("DHF Super-Hi10" manufactured by Daiichi High Frequency Industry Co., Ltd.) was used as a generator of superheated steam, and 10 kg / hour of superheated steam was supplied to the heat treatment furnace. Table 3 shows the evaluation results of the obtained conductive coating film. However, in Examples 10 to 14, the polyimide film with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface resistance | aaaaa | aaaaa |

| Surface resistance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com