Axial pre-tightening mechanism for bearing

A technology of axial preloading and bearings, which is applied in the direction of bearing components, shafts and bearings, rigid supports of bearing parts, etc., can solve the problems of complex process and strong dependence of preloading effect on workers' skills, and achieve convenient use and adjustment Simple, scientifically designed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

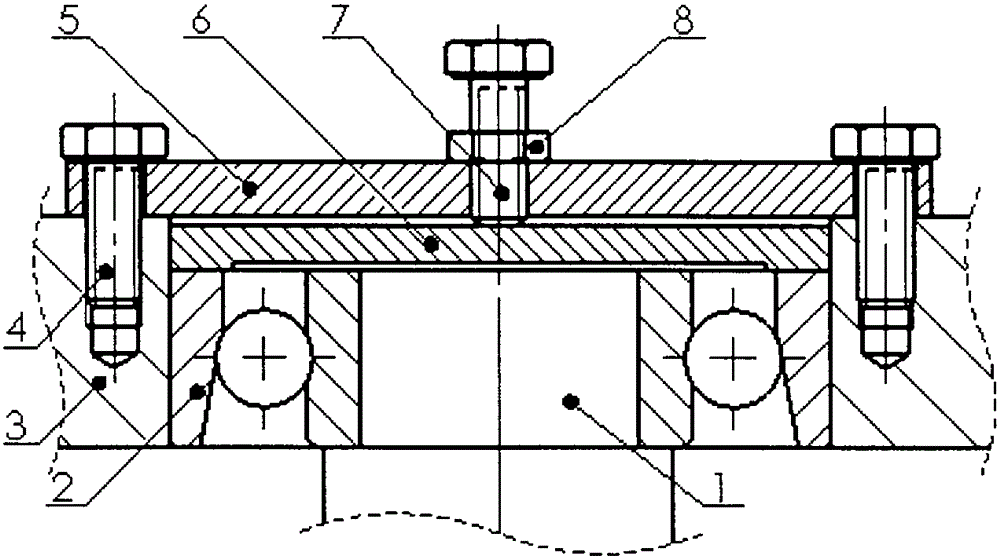

[0018] A bearing axial pre-tightening mechanism includes a bearing cover, a pre-tightening cover, a pre-tightening screw and a lock nut; the end face of the bearing outer ring is axially positioned with the pre-tightening cover, and the pre-tightening screw axially pushes the bearing outer ring through the pre-tightening cover , to realize the axial preload of the bearing and lock it by the lock nut.

[0019] There is a threaded hole in the center of the bearing cover, and the pre-tightening screw is installed in the threaded hole in the center of the bearing cover. There is an annular boss on the edge of the pre-tightening cover, the inner diameter of the boss is larger than the outer diameter of the inner ring of the bearing, and the end face of the outer ring of the bearing is pushed through the end face of the boss.

[0020] The concrete implementation process of this embodiment:

[0021] Install the bearing in the mounting hole of the frame, set the inner hole of the bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com