Acetazolamide tablet and preparation method thereof

A technology of acetazolamide tablets and acetazolamide, which is applied in the field of acetazolamide tablets and its preparation, can solve the problems that drug intraocular pressure cannot be well controlled, acetazolamide is difficult to dissolve in water, and its bioavailability is low. To achieve the effect of improving bioavailability, improving stability and improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0020] Example 1

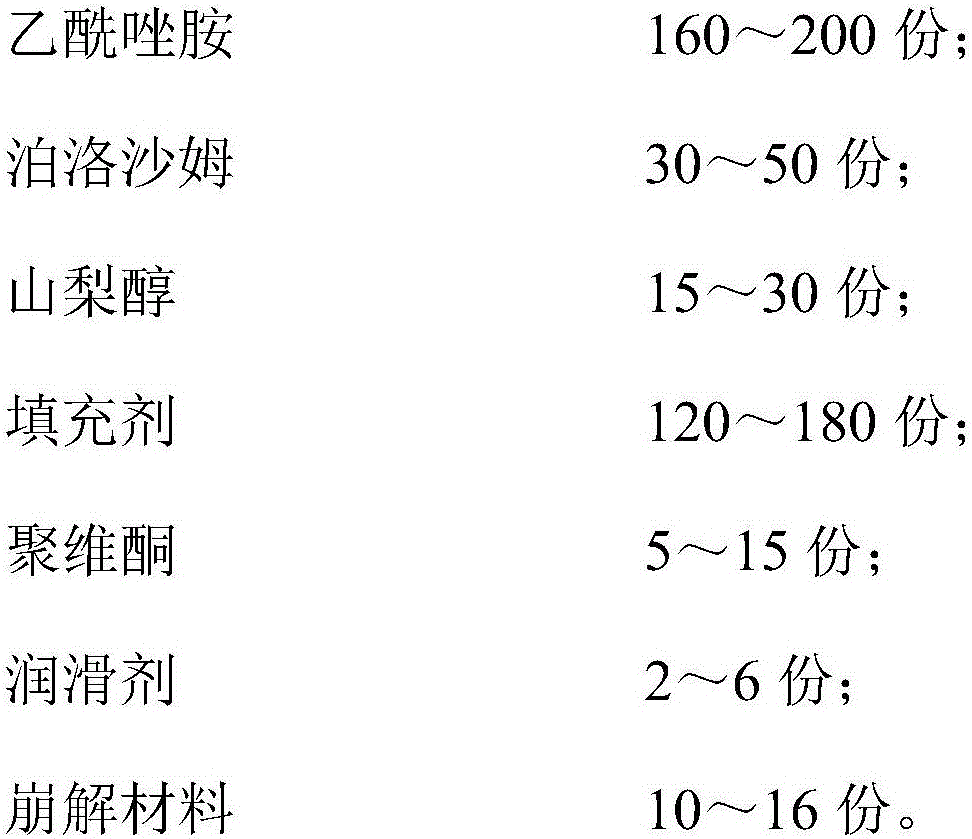

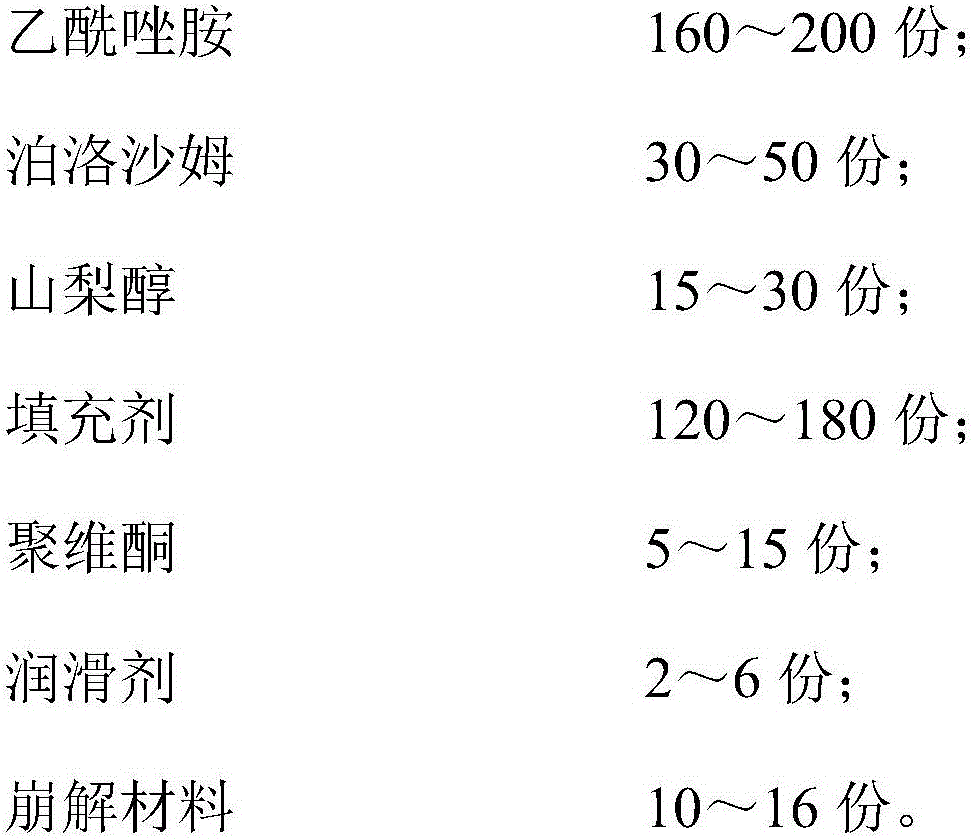

[0021] An acetazolamide tablet, including the following raw materials:

[0022] Acetazolamide 180g, poloxamer 40g, sorbitol 21g, lactose 100g, corn starch 50g, povidone 10g, magnesium stearate 4g, calcium sulfate 5g and sodium carboxymethyl starch 7g.

[0023] The preparation method includes the following steps:

[0024] 1) Pass acetazolamide through a 20-mesh sieve; poloxamer, sorbitol, lactose, corn starch, magnesium stearate, calcium sulfate and sodium carboxymethyl starch are passed through a 30-mesh sieve, and the povidone is dissolved in water Preparation of povidone aqueous solution;

[0025] 2) Weigh acetazolamide, poloxamer and sorbitol into a wet granulator for dry mixing, and then add povidone aqueous solution for wet granulation;

[0026] 3) The granules obtained in step 2) are sized and dried at 70°C for 5 minutes to obtain acetazolamide dry granules;

[0027] 4) After acetazolamide dry granules, corn starch, povidone, magnesium stearate, calcium sulfate a...

Example Embodiment

[0028] Example 2

[0029] An acetazolamide tablet, including the following raw materials:

[0030] Acetazolamide 200g, poloxamer 45g, sorbitol 30g, lactose 100g, corn starch 10g, pregelatinized starch 10g, povidone 7g, zinc stearate 2g, calcium sulfate 5g and sodium carboxymethyl starch 5g.

[0031] The preparation method includes the following steps:

[0032] 1) Pass acetazolamide through a 20-mesh sieve; poloxamer, sorbitol, lactose, corn starch, pregelatinized starch, zinc stearate, calcium sulfate and sodium carboxymethyl starch pass through a 30-mesh sieve. Polyvidone is dissolved in water to prepare an aqueous solution of povidone;

[0033] 2) Weigh acetazolamide, poloxamer and sorbitol into a wet granulator for dry mixing, and then add povidone aqueous solution for wet granulation;

[0034] 3) The granules obtained in step 2) are sized and dried at 65°C for 6 min to obtain acetazolamide dry granules;

[0035] 4) After acetazolamide dry granules, corn starch, pregelatinized starch,...

Example Embodiment

[0036] Example 3

[0037] An acetazolamide tablet, including the following raw materials:

[0038] Acetazolamide 200g, poloxamer 50g, sorbitol 15g, lactose 130g, corn starch 50g, povidone 15g, magnesium stearate 6g, calcium sulfate 5g and sodium carboxymethyl starch 11g.

[0039] The preparation method includes the following steps:

[0040] 1) Pass acetazolamide through a 20-mesh sieve; poloxamer, sorbitol, lactose, corn starch, magnesium stearate, calcium sulfate and sodium carboxymethyl starch are passed through a 30-mesh sieve. Vitone aqueous solution;

[0041] 2) Weigh acetazolamide, poloxamer and sorbitol into a wet granulator for dry mixing, and then add povidone aqueous solution for wet granulation;

[0042] 3) The granules obtained in step 2) are sized and dried at 60°C for 8 minutes to obtain acetazolamide dry granules;

[0043] 4) After acetazolamide dry granules, corn starch, povidone, magnesium stearate, calcium sulfate and sodium carboxymethyl starch are mixed uniformly, the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap