Column Cationic Reverse Flotation Process for Micro-grained Hematite

A technology of hematite and fine particles, applied in flotation, solid separation, etc., can solve the problems of complex flotation process and reagent system, high-temperature flotation of anion reverse flotation process, large equipment footprint, etc., and achieve reduction The grade of flotation tailings, the suppression effect is good, and the effect of reducing the occupied area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: The column type cationic reverse flotation process of the micro-grained hematite adopts the following raw materials and process steps.

[0037] Raw material: select the reverse flotation feed in the hematite treatment process (stage grinding, coarse and fine classification, gravity separation-magnetic separation-reverse flotation) of Sijiaying Iron Ore Concentrator in Tangshan area. The metal minerals of the raw material are mainly hematite, magnetite, semi-pseudo-hematite, and pseudo-hematite; the gangue minerals are mainly quartz. The feed grade of reverse flotation roughing is TFe39.89%, the fineness -200 mesh accounts for 90.46%, and the pulp concentration is 35wt%.

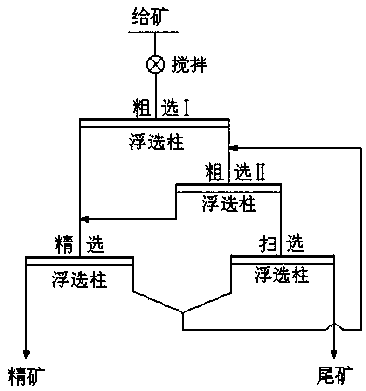

[0038] Process steps: As shown in the figure, the flotation feed ore first enters the mixing tank to add medicine to adjust the slurry and mix. The primary roughing flotation column performs the first roughing, the foam product of the primary roughing flotation column enters the secondar...

Embodiment 2

[0039] Embodiment 2: The column type cationic reverse flotation process of the micro-grained hematite adopts the following raw materials and process steps.

[0040] Raw material: Hematite ore mined from the surface mine of Sijiaying Iron Mine in Tangshan area is selected for reverse flotation feeding in the process of stage grinding, coarse and fine classification, gravity separation-magnetic separation-reverse flotation. The mineral composition of this raw material is simple, mainly hematite and limonite, followed by magnetite, and a small amount of false and half false hematite. The gangue minerals are mainly quartz, followed by actinolite and so on. The feed grade of reverse flotation roughing is TFe42.15%, the fineness -200 mesh accounts for 92.61%, and the pulp concentration is 30 wt%.

[0041]Process step is basically the same as embodiment 1. The specific reagent system for cationic reverse flotation is: the amount of starch added in the primary roughing is 1300g / t, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com