A pipeline object location method based on fusion of vision and code disc data

An assembly line and code disc technology, applied in the direction of instruments, sorting, measuring devices, etc., can solve the problems of expensive operation, complexity, and lack of universality, and achieve the effect of high calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1. This embodiment provides an assembly line object positioning method based on fusion of vision and code disc data. Using multi-eye cameras and incremental code discs, the operable space of the control system is expanded, and the speed change of the conveyor belt can be handled. Objects on the assembly line; when used, the specific pose of the object on the assembly line conveyor belt can be obtained, which enhances the operability of the system.

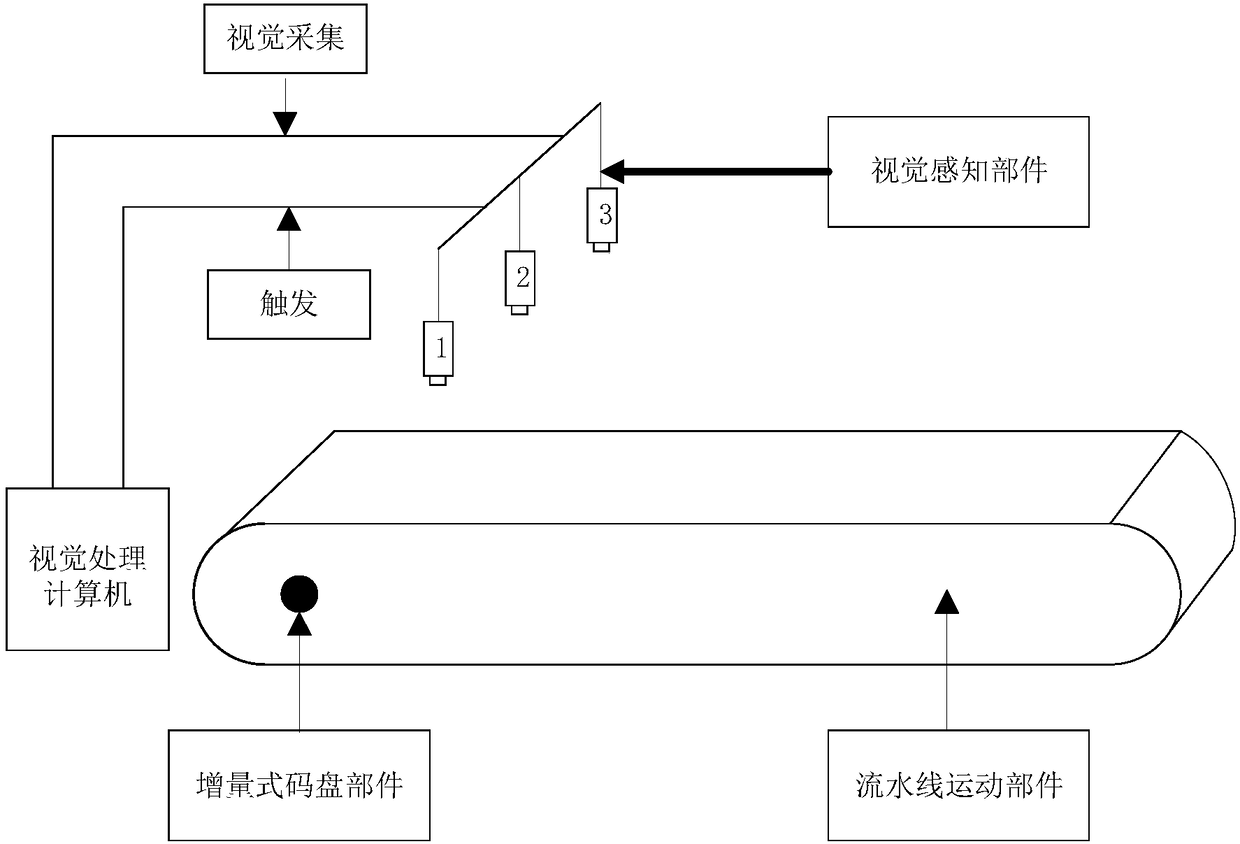

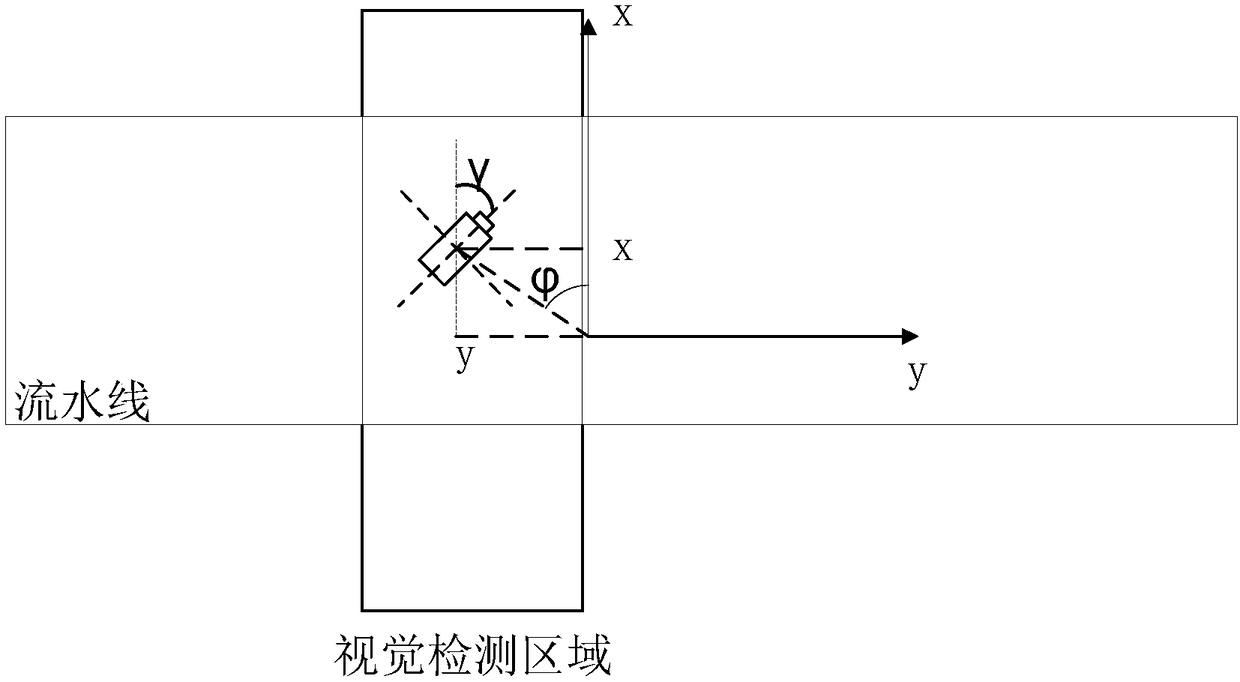

[0025] positioning devices such as figure 1 As shown, it includes assembly line moving parts, visual sensing parts, and incremental code disc parts, wherein the visual sensing part adopts trinocular cameras, cameras 1 and 3 are auxiliary cameras, and camera 2 is the main camera. figure 2 is a schematic flow chart of the object positioning method according to the embodiment of the present invention. Such as figure 2 As shown, the positioning method includes:

[0026] Step 1: The camera installed above the asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com