A kind of room temperature liquid phase method prepares the method for SNSE microsphere

A technology of microsphere and liquid phase method, which is applied in the direction of binary selenium/tellurium compounds, metal selenide/telluride, etc., can solve the problems of long reaction time, high synthesis cost, secondary pollution, etc., and achieve energy saving and Generates cost, high repeatability, small product size effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add 0.1579g of selenium powder to 10mL of hydrazine hydrate, stir until the selenium powder is completely dissolved to form wine red solution A; weigh 0.2256g of SnCl 2 2H 2 O was added to the above solution A, and stirred until it turned into light yellow solution B; put solution B on a magnetic stirrer and stirred at a speed of 500r / min for 2h, after which solution B gradually turned black. Then, the solution B was centrifuged to obtain a black powder, which was repeatedly washed with absolute ethanol for 3 times and dried to obtain SnSe microspheres.

Embodiment 2

[0025] Add 0.3158g of selenium powder to 20mL of hydrazine hydrate, stir until the selenium powder is completely dissolved to form wine red solution A; weigh 0.6g of SnCl 2 2H 2 O was added to the above solution A, and stirred until it turned into a light yellow solution B; the solution B was placed on a magnetic stirrer and stirred at a speed of 800r / min for 3 hours, and then the solution B gradually turned black. Then, the solution B was centrifuged to obtain a black powder, which was repeatedly washed with absolute ethanol for 3 times and dried to obtain SnSe microspheres.

Embodiment 3

[0027] Add 0.6316g of selenium powder to 25mL of hydrazine hydrate, stir until the selenium powder is completely dissolved to form wine red solution A; weigh 1.0g of SnCl 2 2H 2 O was added to the above solution A, and stirred until it turned into light yellow solution B; put solution B on a magnetic stirrer and stirred at a speed of 900r / min for 3h, after which solution B gradually turned black. Then, the solution B was centrifuged to obtain a black powder, which was repeatedly washed with absolute ethanol for 3 times and dried to obtain SnSe microspheres.

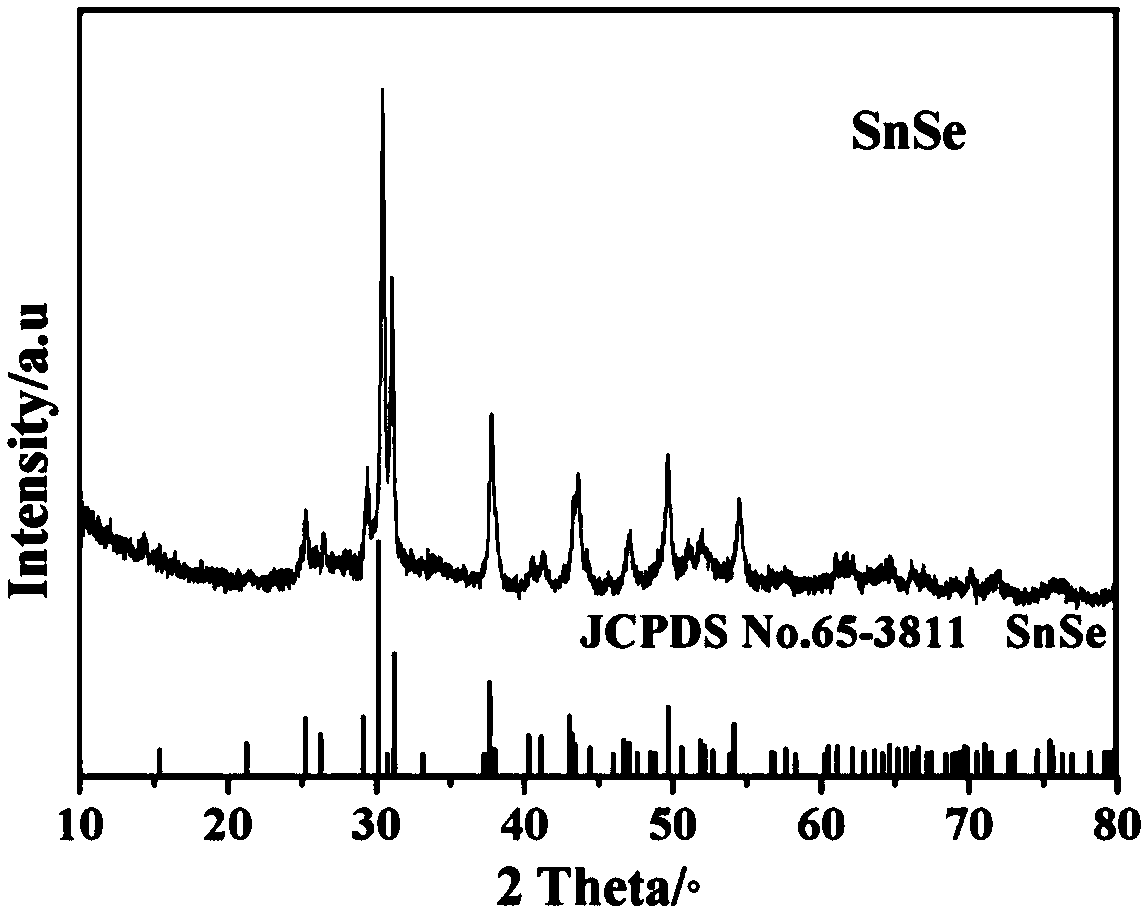

[0028] The sample (SnSe microspheres) was analyzed with a Rigaku D / max2000PC X-ray diffractometer, and it was found that the sample was consistent with the orthorhombic SnSe structure of JCPDS No. 65-3811, indicating that this method can produce pure phase SnSe. Observing the sample with a field emission scanning electron microscope (FESEM), it can be seen that the prepared SnSe product is a uniform microsphere of 0.5-1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com