Reuse and salt-reclamation treatment method for desulfurization wastewater

A technology for desulfurization wastewater and treatment methods, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of increased chemical dosage, secondary pollution, and high treatment costs , to achieve the effect of enhancing industrial value, avoiding waste of resources, and rationally allocating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

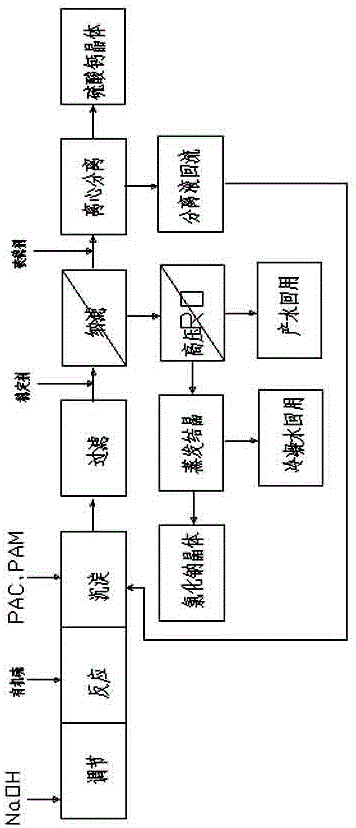

Image

Examples

Example Embodiment

[0025] Example 1:

[0026] The steps of this desulfurization wastewater reuse and salt recycling method are as follows:

[0027] 1) Add caustic soda to the desulfurization wastewater to be treated, adjust the pH value to 9, and add organic sulfur, coagulant and flocculant at the same time to react and precipitate the suspended solids, heavy metals and colloidal impurities in the water, and the sludge is sent to landfill On-site treatment, the effluent is neutralized with hydrochloric acid to pH 6;

[0028] The dosing method of the caustic soda is as follows: the caustic soda is configured into a solution with a mass percentage concentration of 10%, and the caustic soda is continuously and quantitatively added to a pH value of 9 through a metering pump;

[0029] The organic sulfur is TMT-15 (purchased from Suzhou Rundongyuan Environmental Protection Technology Co., Ltd.), and the dosing method is: configure the organic sulfur into a solution with a mass percentage concentratio...

Example Embodiment

[0037] Example 2:

[0038] The steps of this desulfurization wastewater reuse and salt recycling method are as follows:

[0039] 1) Add caustic soda to the desulfurization wastewater to be treated, adjust the pH to 10, and add organic sulfur, coagulant and flocculant at the same time to react and precipitate suspended solids, heavy metals and colloidal impurities in the effluent, and the sludge is sent to landfill On-site treatment, the effluent is neutralized with hydrochloric acid to pH 7;

[0040] The dosing method of the caustic soda is as follows: the caustic soda is configured into a solution with a mass percentage concentration of 15%, and the caustic soda is continuously and quantitatively added to a pH value of 10 through a metering pump;

[0041] The organic sulfur is TMT-15 (purchased from Suzhou Rundongyuan Environmental Protection Technology Co., Ltd.), and the dosing method is: configure the organic sulfur into a solution with a mass percentage concentration of ...

Example Embodiment

[0049] Example 3:

[0050] The steps of this desulfurization wastewater reuse and salt recycling method are as follows:

[0051] 1) Add caustic soda to the desulfurization wastewater to be treated, adjust the pH value to 9, and add organic sulfur, coagulant and flocculant at the same time to react and precipitate the suspended solids, heavy metals and colloidal impurities in the water, and the sludge is sent to landfill On-site treatment, the effluent is neutralized with hydrochloric acid to pH 7;

[0052] The dosing method of the caustic soda is as follows: the caustic soda is configured into a solution with a mass percentage concentration of 13%, and the caustic soda is continuously and quantitatively added to a pH value of 9 through a metering pump;

[0053] The organic sulfur is TMT-15 (purchased from Suzhou Rundongyuan Environmental Protection Technology Co., Ltd.), and the dosing method is: configure the organic sulfur into a solution with a mass percentage concentratio...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap