A kind of epoxy resin heat conducting composite material and its preparation and application

A heat-conducting composite material and epoxy resin technology, applied in the field of thermal interface materials, can solve problems such as poor thermal conductivity, low viscosity, and low viscosity, and achieve the effects of improving heat exchange efficiency, improving interaction, and reducing system viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

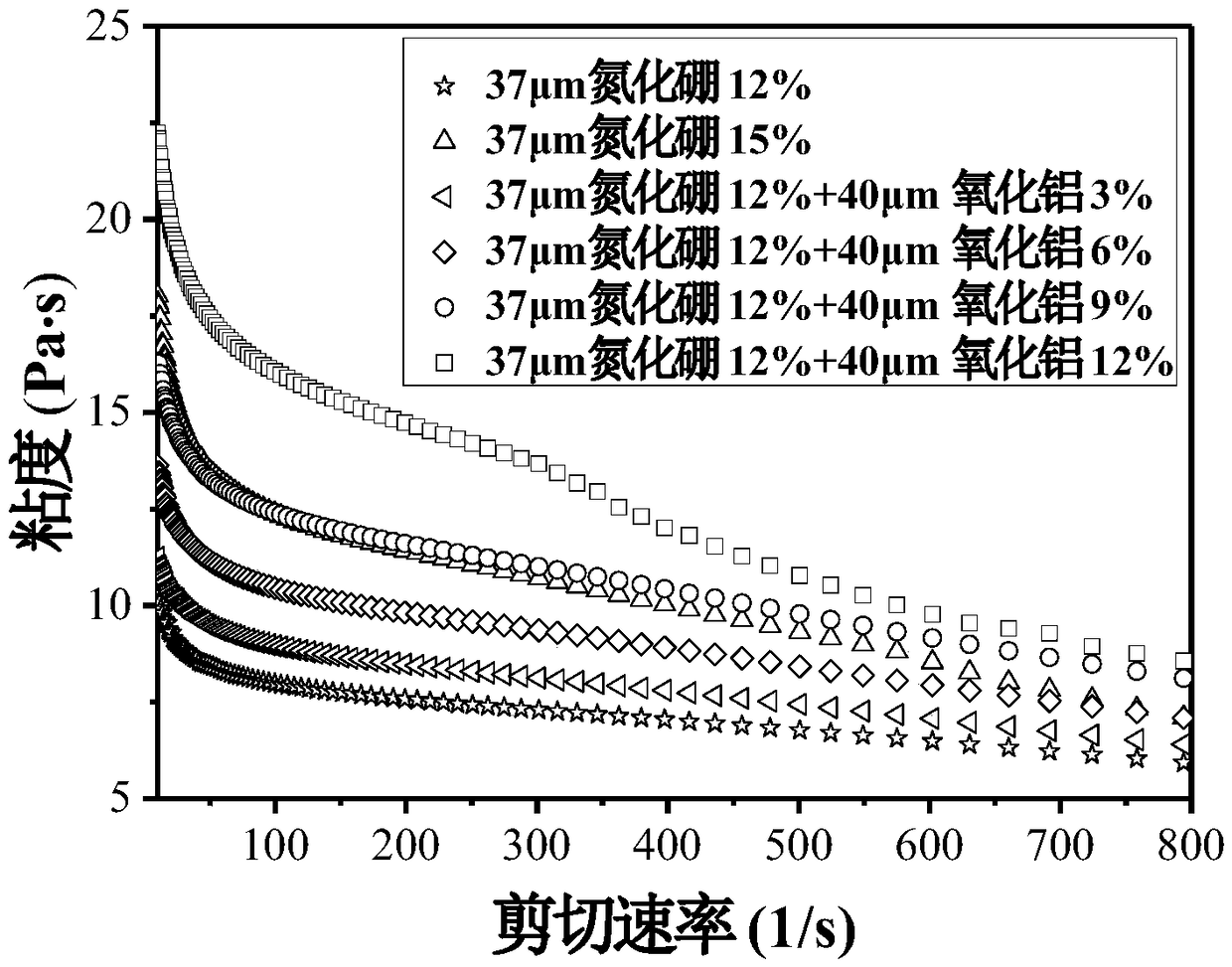

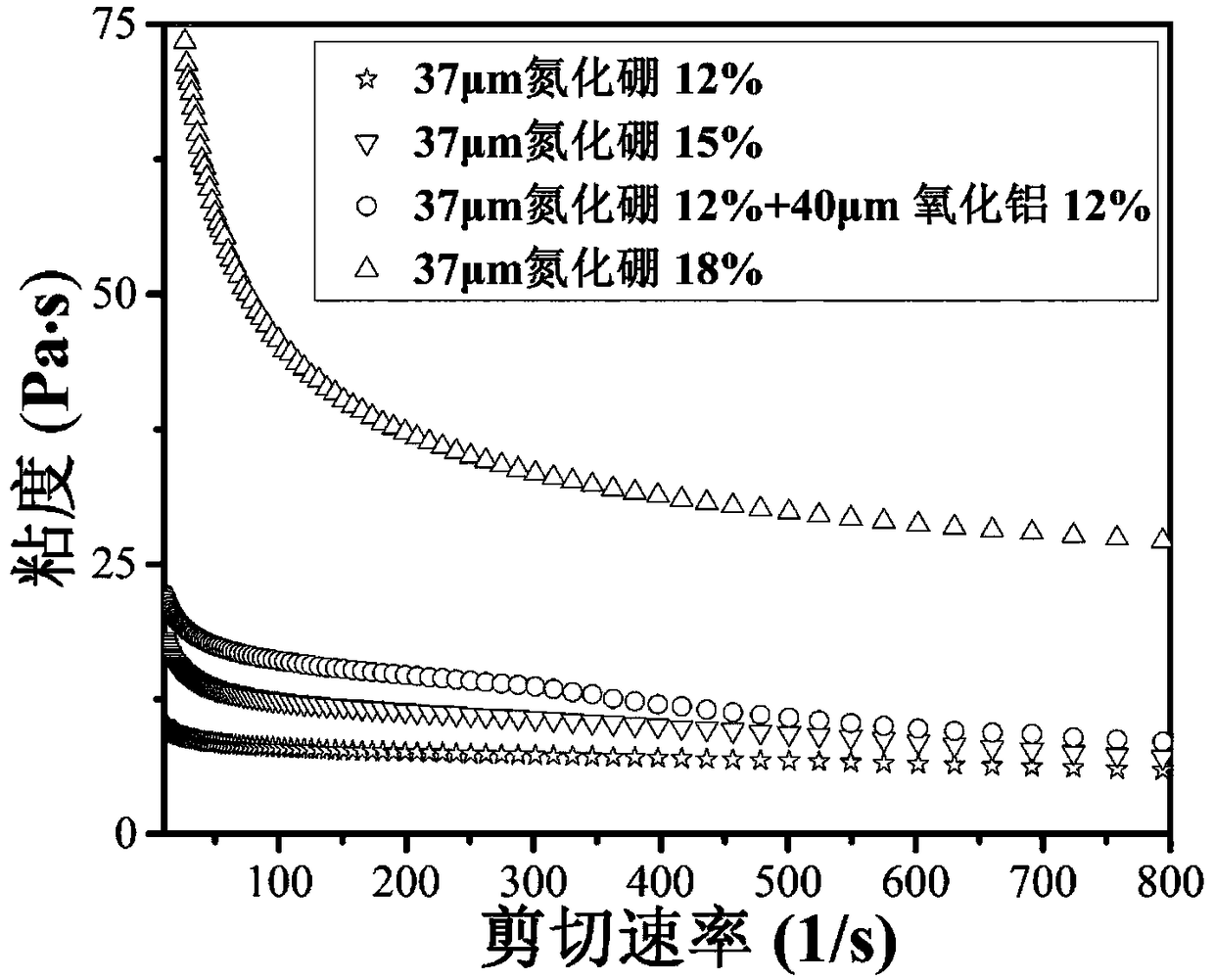

[0046] An epoxy resin composite material, in which an inorganic filler with a volume ratio of 12% is uniformly dispersed in the epoxy resin, the inorganic filler includes a two-dimensional lamellar inorganic filler, and the average particle diameter of the two-dimensional lamellar inorganic filler is 37 Micron, the two-dimensional sheet inorganic filler is boron nitride. The thermal conductivity of the epoxy resin composite material is tested according to the test standard ASTM C1113, the thermal conductivity is 0.81W / m·K, and the viscosity is 7.8Pa·s at 30°C.

[0047] An epoxy resin composite material is prepared according to the following method according to the formula ratio:

[0048] (1) Take the two-dimensional lamellar inorganic filler and fully dry the filler.

[0049] (2) Add the two-dimensional lamellar inorganic filler obtained in step (1) into the epoxy resin, disperse evenly, and solidify after degassing to obtain the epoxy resin composite material. Described epo...

Embodiment 2

[0056] An epoxy resin composite material, in which an inorganic filler with a volume ratio of 15% is uniformly dispersed in the epoxy resin, the inorganic filler includes a two-dimensional lamellar inorganic filler, and the average particle diameter of the two-dimensional lamellar inorganic filler is 37 Micron, the two-dimensional sheet inorganic filler is boron nitride. The thermal conductivity of the epoxy resin composite material is tested according to the test standard ASTM C1113, the thermal conductivity is 1.01W / m·K, and the viscosity is 12.8Pa·s at 30°C.

[0057] An epoxy resin composite material is prepared according to the following method according to the formula ratio:

[0058] (1) Take the two-dimensional lamellar inorganic filler and fully dry the filler.

[0059] (2) Add the two-dimensional lamellar inorganic filler obtained in step (1) into the epoxy resin, disperse evenly, and solidify after degassing to obtain the epoxy resin composite material. Described ep...

Embodiment 3

[0066] An epoxy resin composite material, in which an inorganic filler with a volume ratio of 18% is uniformly dispersed in the epoxy resin, the inorganic filler includes a two-dimensional lamellar inorganic filler, and the average particle diameter of the two-dimensional lamellar inorganic filler is 37 Micron, the two-dimensional sheet inorganic filler is boron nitride. The thermal conductivity of the epoxy resin composite material is tested according to the test standard ASTM C1113, the thermal conductivity is 1.09W / m·K, and the viscosity is 42.8Pa·s at 30°C.

[0067] An epoxy resin composite material is prepared according to the following method according to the formula ratio:

[0068] (1) Take the two-dimensional lamellar inorganic filler and fully dry the filler.

[0069] (2) Add the two-dimensional lamellar inorganic filler obtained in step (1) into the epoxy resin, disperse evenly, and solidify after degassing to obtain the epoxy resin composite material. Described ep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com