A sewing machine needle bar branch body

A sewing machine needle and support technology, which is applied to sewing machine needle holders, sewing machine components, sewing equipment, etc., can solve the problems of difficult breakthroughs in technology and difficult to obtain needle bar supports with comprehensive performance, and achieve good comprehensive performance, improve strength, Compatible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

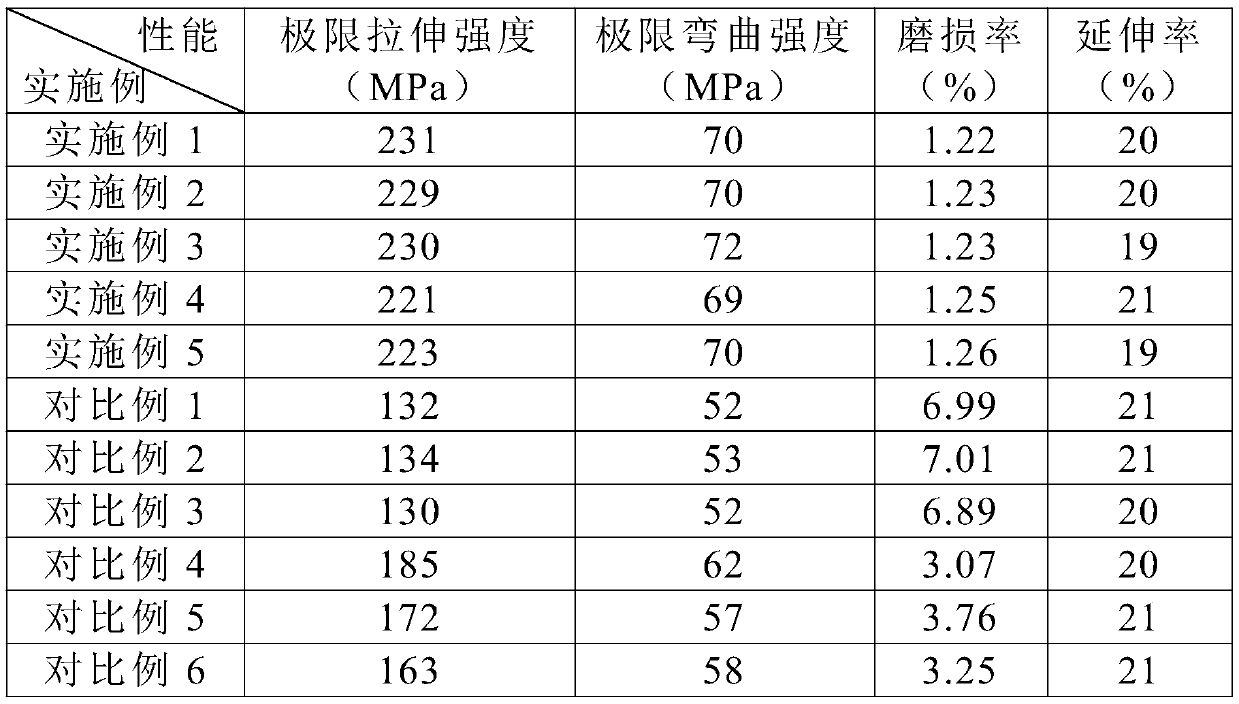

Examples

Embodiment 1

[0023] A needle bar support body of a sewing machine, the needle bar support body is made of a ceramic skeleton reinforced aluminum matrix composite material, and the ceramic skeleton reinforced aluminum matrix composite material includes superhard wear-resistant particles with a volume ratio of 8%, and a volume ratio of A 25% ceramic skeleton and an aluminum alloy matrix with a volume ratio of 67% are compounded by pressure infiltration, wherein the aluminum alloy matrix is composed of the following mass percentages: Mg: 3.0%, Si: 1.6%, Cr: 0.55 %, Cu: 0.16%, Mn: 0.16%, Zn: 0.18%, Ni: 0.6%, B: 0.20%, Zr: 0.07%, Sc: 0.09%, and the balance is Al and unavoidable impurities.

[0024] The porous polyurethane foam is dipped and coated with silicon nitride ceramic slurry to make a green body, and then sintered to form a three-dimensional network silicon nitride ceramic framework. .

[0025] The above-mentioned aluminum alloy is smelted into aluminum liquid, and the above-mentione...

Embodiment 2

[0027]A sewing machine needle bar support body, the needle bar support body is made of a ceramic skeleton reinforced aluminum matrix composite material, the ceramic skeleton reinforced aluminum matrix composite material includes superhard wear-resistant particles with a volume ratio of 6%, and a volume ratio of A 28% ceramic skeleton and an aluminum alloy matrix with a volume ratio of 66% are compounded by pressure infiltration, wherein the aluminum alloy matrix is composed of the following mass percentages: Mg: 3.5%, Si: 1.5%, Cr: 0.50 %, Cu: 0.145%, Mn: 0.16%, Zn: 0.16%, Ni: 0.2%, B: 0.13%, Zr: 0.06%, Sc: 0.08%, and the balance is Al and unavoidable impurities.

[0028] The porous polyurethane foam is dipped and coated with silicon nitride ceramic slurry to make a green body, and then sintered to form a three-dimensional network silicon nitride ceramic framework. .

[0029] The above-mentioned aluminum alloy is smelted into aluminum liquid, and the above-mentioned three-d...

Embodiment 3

[0031] A sewing machine needle bar support body, the needle bar support body is made of ceramic skeleton reinforced aluminum matrix composite material, the ceramic skeleton reinforced aluminum matrix composite material includes superhard wear-resistant particles with a volume ratio of 8%, and the volume ratio is A 22% ceramic skeleton and an aluminum alloy matrix with a volume ratio of 70% are compounded by pressure infiltration, wherein the aluminum alloy matrix is composed of the following mass percentages: Mg: 2.6%, Si: 1.7%, Cr: 0.48 %, Cu: 0.17%, Mn: 0.15%, Zn: 0.2%, Ni: 1.2%, B: 0.15%, Zr: 0.09%, Sc: 0.09%, and the balance is Al and unavoidable impurities.

[0032] The porous polyurethane foam is dipped and coated with silicon nitride ceramic slurry to make a green body, and then sintered to form a three-dimensional network silicon nitride ceramic framework. .

[0033] The above-mentioned aluminum alloy is smelted into molten aluminum, and the above-mentioned three-di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com