Deep stirring ship processor

A deep mixing and processing machine technology, applied in soil protection, sheet pile walls, construction, etc., can solve the problems of poor reliability and low efficiency, and achieve the effect of increasing the processing depth and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

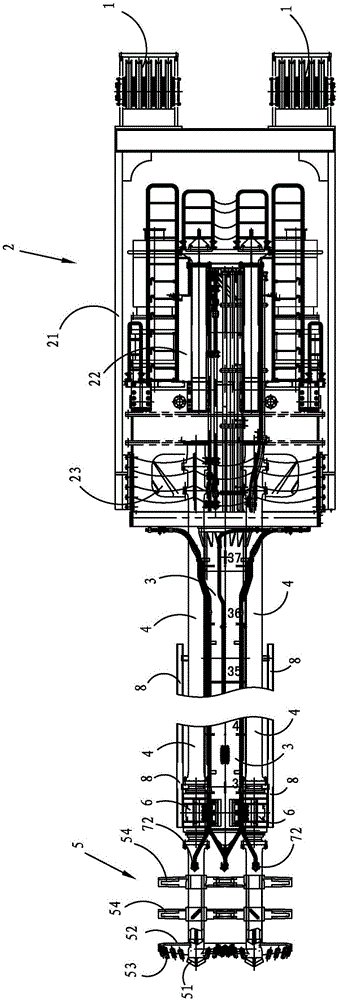

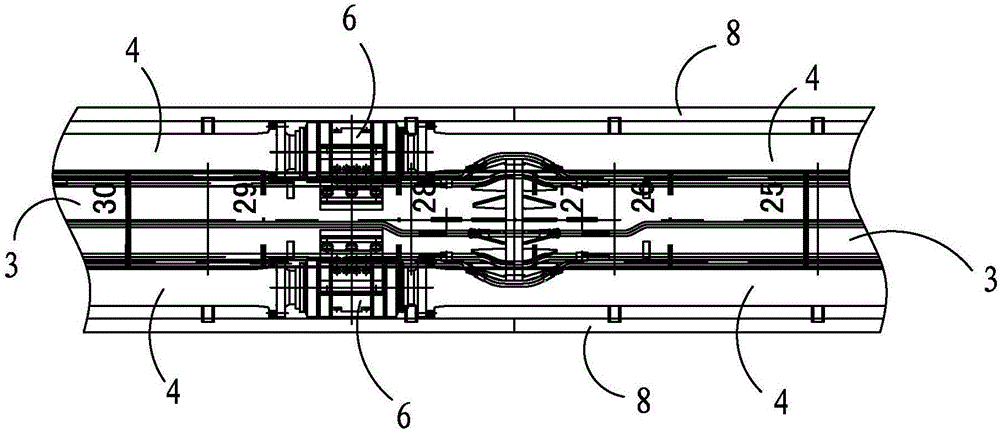

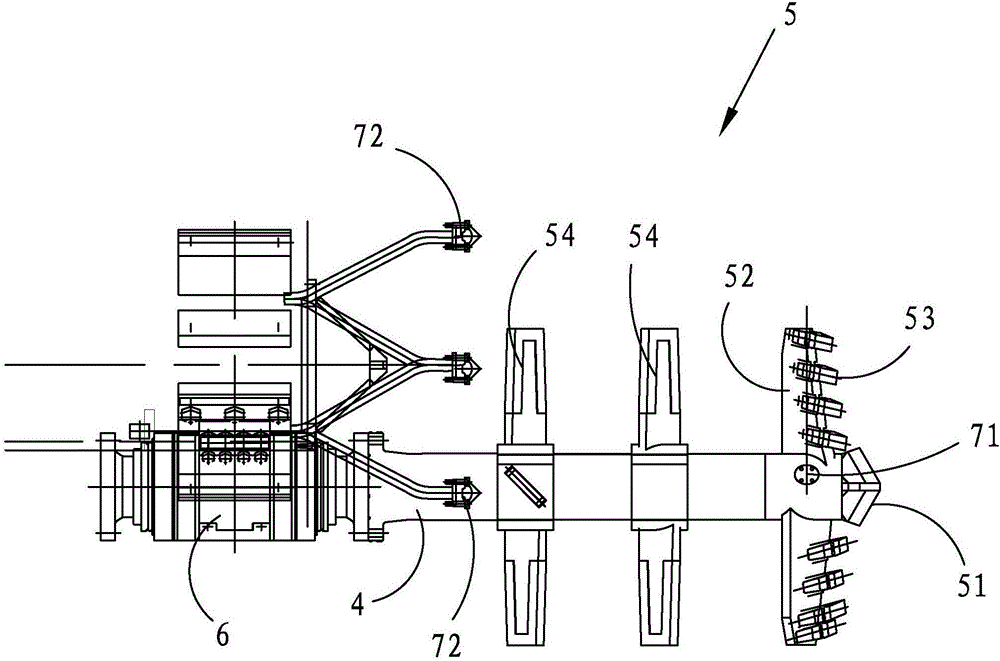

[0024] Example 1: Participation figure 1 As shown, a deep mixing vessel processor includes a hoisting part 1, a driving part fixedly arranged under the hoisting part 1, a main shaft 3 fixedly arranged under the driving part 2 and extending vertically downward, parallel to the main shaft 3 The stirring shaft 4 and the stirring wing 5 fixedly arranged at the lower end of the stirring shaft 4 are arranged. The stirring wing 5 is arranged at the lower end of the main shaft 3, and the driving part 2 drives the stirring shaft 4 to autotransmit. The main shaft 3 is provided with a plurality of bearings for carrying The stirring shaft bearings 6 of the stirring shaft 4 and the stirring shafts 4 are provided with four stirring shafts 4, which are evenly distributed along the outer ring of the main shaft 3, and the rotation directions of two adjacent stirring shafts 4 are arranged in opposite directions. In addition, at least a part of the stirring areas of the two adjacent stirring wings...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com