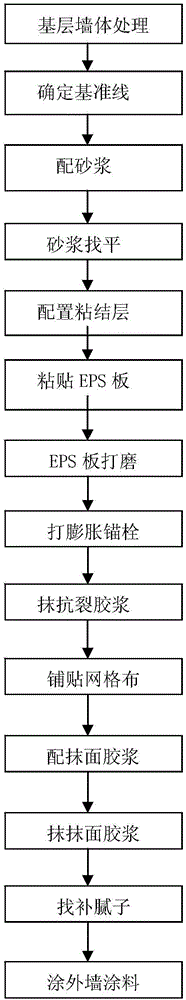

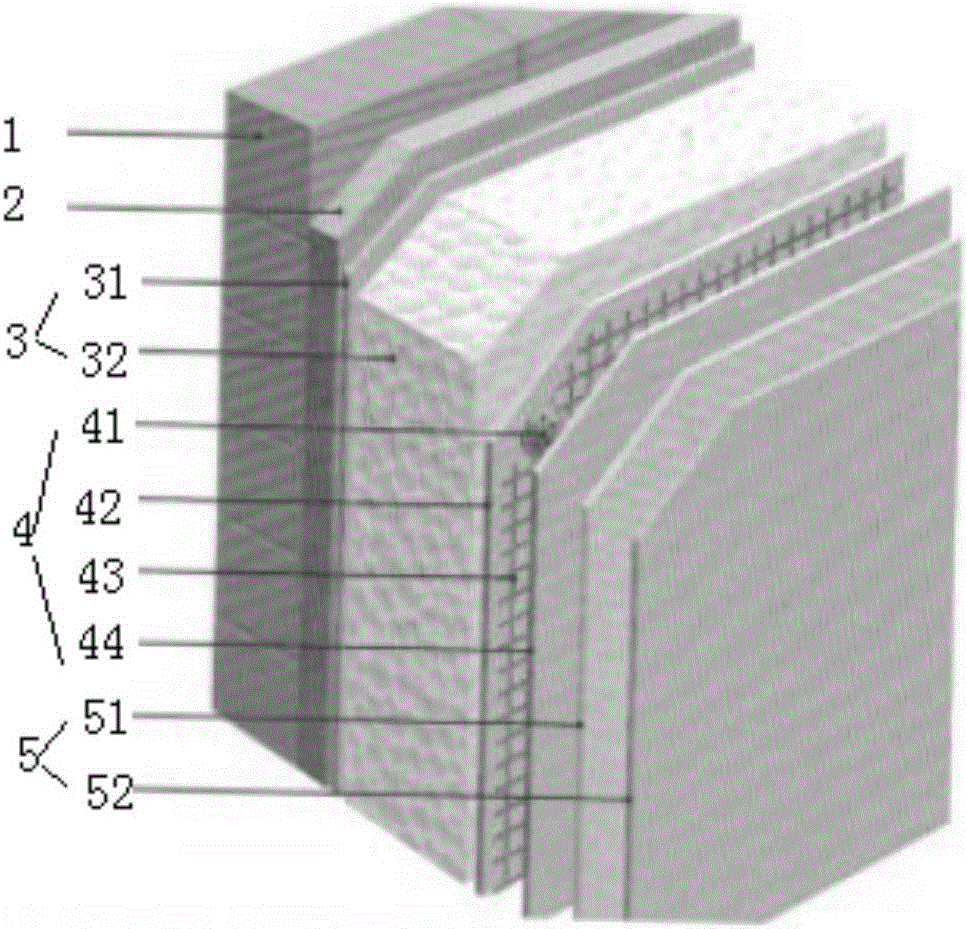

Construction method for EPS wall body insulation structure

A construction method and wall technology, applied in thermal insulation, building components, building structures, etc., can solve the problems of insufficient bonding strength of the thermal insulation layer, easy damage of the wall thermal insulation system, poor thermal insulation effect, etc., and achieve good economic benefits and Market prospect, good heat preservation effect and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The specific steps of the construction method of the EPS wall insulation structure involved in this embodiment are:

[0039] (1) Base wall 1 pretreatment: clean up the floating ash and debris remaining on the base wall before construction, then repair and plug the hole. When plugging the hole, first wet the inner surface of the wall hole with a damp cloth, and then Waterproof cement, medium sand and water are mixed in a weight ratio of 1:3:0.6, and then 4% expansion agent of the weight of the waterproof cement is added. After mixing and mixing, the cement mortar is prepared, and then the hole is plugged from the inside of the wall, and the hole is filled The thickness of the cement mortar is 15-25mm. After standing for 10-15 minutes until the cement mortar in the hole is solidified, the cement mortar is re-mixed evenly, and then the hole is plugged from the outside of the wall, and the hole is filled with cement mortar. Finally, the wall surface is smoothed, compacted and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com