Calorimeter

A technology for a calorimeter and a heating device, applied in the field of calorimeters, can solve the problems of large overall volume and complex structure of the calorimeter, and achieve the effect of reducing the volume and simplifying the overall structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

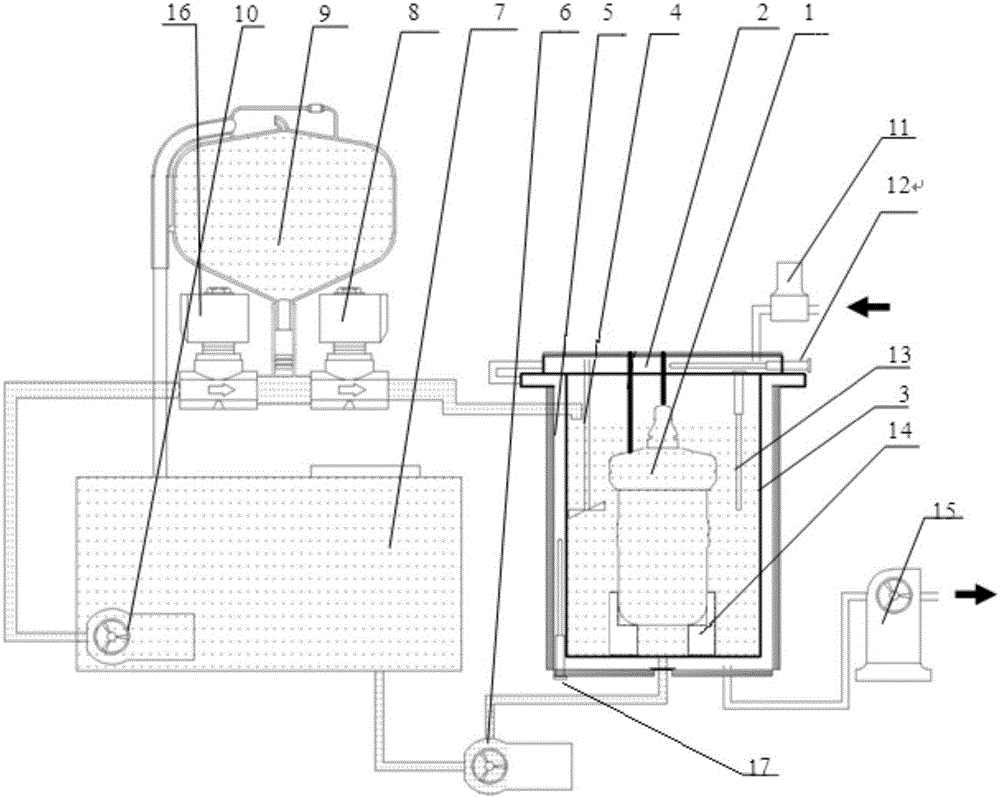

[0024] Such as figure 1 As shown, a calorimeter provided in this embodiment includes an oxygen bomb 1, an inner cylinder 3, an outer cylinder 5, a temperature control cover 2 and a control unit.

[0025] The oxygen bomb 1 is set in the inner cylinder 3 through the oxygen bomb bracket 14, the inner cylinder 3 is filled with liquid that has not passed through the oxygen bomb 1, and the inner cylinder 3 is provided with a meter for measuring the liquid. The temperature of the first temperature sensor 13 . The first temperature sensor 13 is connected with the control unit.

[0026] The outer cylinder 5 is sheathed on the outside of the inner cylinder 3 . An air interlayer is provided between the outer cylinder 5 and the inner cylinder 3 . The air interlayer is provided with a third temperature sensor 17 for measuring the temperature of the gas in the air interlayer, and the third temperature sensor 17 is connected with the control unit.

[0027] The temperature control cover 2...

Embodiment 2

[0035] This embodiment is basically the same as Embodiment 1. For the sake of brevity, in the description process of this embodiment, the same technical features as Embodiment 1 will not be described, and only the differences between this embodiment and Embodiment 1 will be described:

[0036] Wherein, the water circulation system of the inner cylinder is also included, and the water circulation system of the inner cylinder is used for replacing the liquid in the inner cylinder.

[0037] Wherein, the inner cylinder water circulation system includes a constant temperature water tank and a measuring cup, the water inlet of the constant temperature water tank is connected to the water outlet of the inner cylinder, and the water outlet of the constant temperature water tank is connected to the water inlet of the inner cylinder through the measuring cup A water inlet valve is provided at the connection between the water outlet of the constant temperature water tank and the measuring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com