Low-VOC (Volatile Organic Compounds) low-smell automobile double-wall heat shrink tube and preparation method thereof

A double-wall heat-shrinkable tube and low-odor technology, applied to electrical components, conductors, circuits, etc., can solve the problems that double-walled tubes cannot pass VOC and odor level tests, and achieve a good appearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0041] The preparation method of the low-VOC and low-odor automobile double-wall heat-shrinkable tube comprises the following steps:

[0042] Step 1: Preparation of Exterior Wall Masterbatch:

[0043] Each material is weighed by weight, but half of the deodorant masterbatch is weighed, and the resin, pellets and powder are put into the high-speed mixer in turn and stirred evenly;

[0044] The mixed materials are melted and extruded in a parallel twin-screw extruder with a vacuum port, drawn, cooled, and pelletized. The temperature is set to 90-170 ° C, and the temperature of the first and second stages of the extruder is set to a low temperature. At the boiling point of the liquid stripping agent, the vacuum degree is -0.03~-0.1MPa;

[0045] Stir the prepared granules and the other half of the deodorant masterbatch in a high-speed mixer evenly;

[0046]The uniformly mixed material is melted and extruded for the second time in a parallel twin-screw extruder with a vacuum port...

Example

[0052] Preparation Example 1:

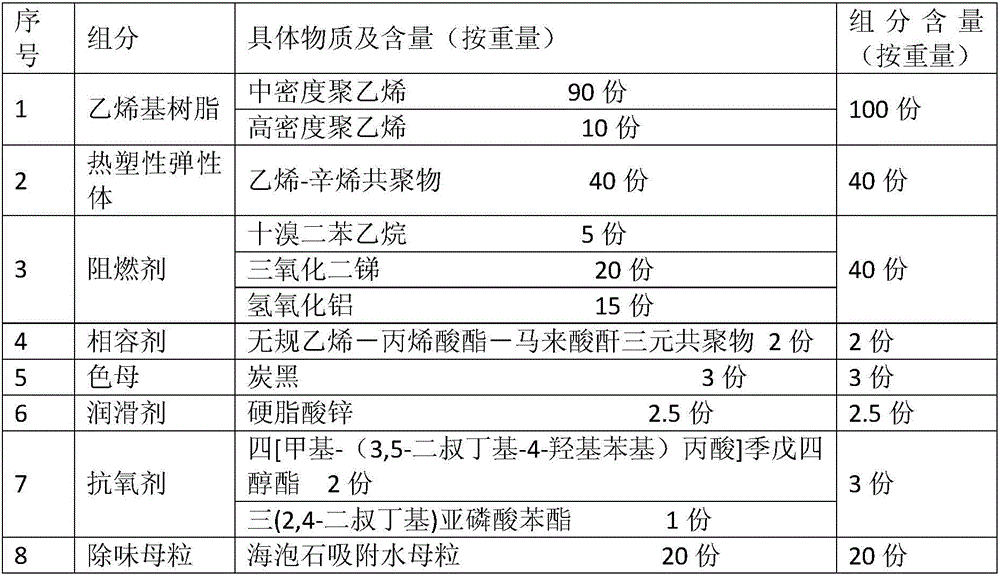

[0053] The components are weighed according to the weights listed in the table below.

[0054]

[0055] Weigh each material by weight (half of the deodorant masterbatch is weighed), put resin, pellets and powder into the high-speed mixer in turn and stir evenly;

[0056] The mixed material is melted and extruded in a parallel twin-screw extruder with a vacuum port, drawn, cooled, and pelletized. The temperature of the first and second stages of the extruder is set to 90 °C, and the vacuum degree is -0.05MPa ;

[0057] Stir the granulated material and the other half of the deodorant masterbatch evenly in a high-speed mixer; the uniformly mixed material is extruded, granulated and dried for the second time, and the temperature of the first and second stages of the extruder is set to 90 ℃, the degree of vacuum is -0.05MPa.

[0058] The outer wall masterbatch and the inner wall hot-melt adhesive are co-extruded, and the pipe material is cross-...

Example

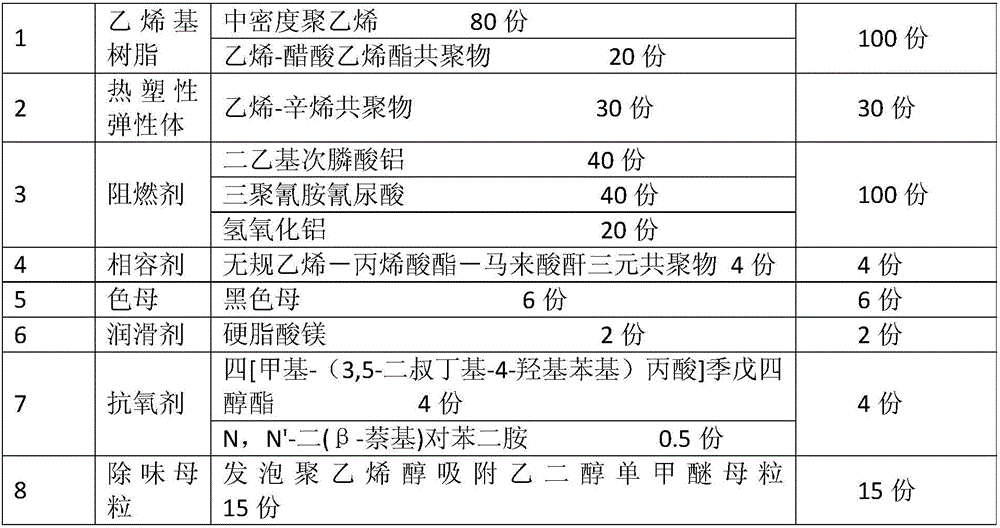

[0066] Preparation Example 2

[0067] The components are weighed according to the weights listed in the table below.

[0068]

[0069]

[0070] Weigh each material by weight (weigh half of the masterbatch for deodorization), put resin in turn in a high-speed mixer, and stir the pellets and powder evenly;

[0071] The mixed material is melted and extruded in a parallel twin-screw extruder with a vacuum port, drawn, cooled, and pelletized. The temperature of the first and second stages of the extruder is set to 90 °C, and the vacuum degree is -0.05MPa ;

[0072] Stir the granulated material and the other half of the deodorant masterbatch evenly in a high-speed mixer; the uniformly mixed material is extruded, granulated and dried for the second time, and the temperature of the first and second stages of the extruder is set to 90 ℃, the degree of vacuum is -0.05MPa.

[0073] The outer wall masterbatch and the inner wall hot-melt adhesive are co-extruded, and the pipe mate...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap