Testing device and testing method for temperature sensor consistency

A temperature sensor and testing device technology, which is applied in the field of temperature sensors, can solve the problems of expensive constant temperature liquid tanks, and achieve the effects of high cost performance, uniform liquid temperature, and high testing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

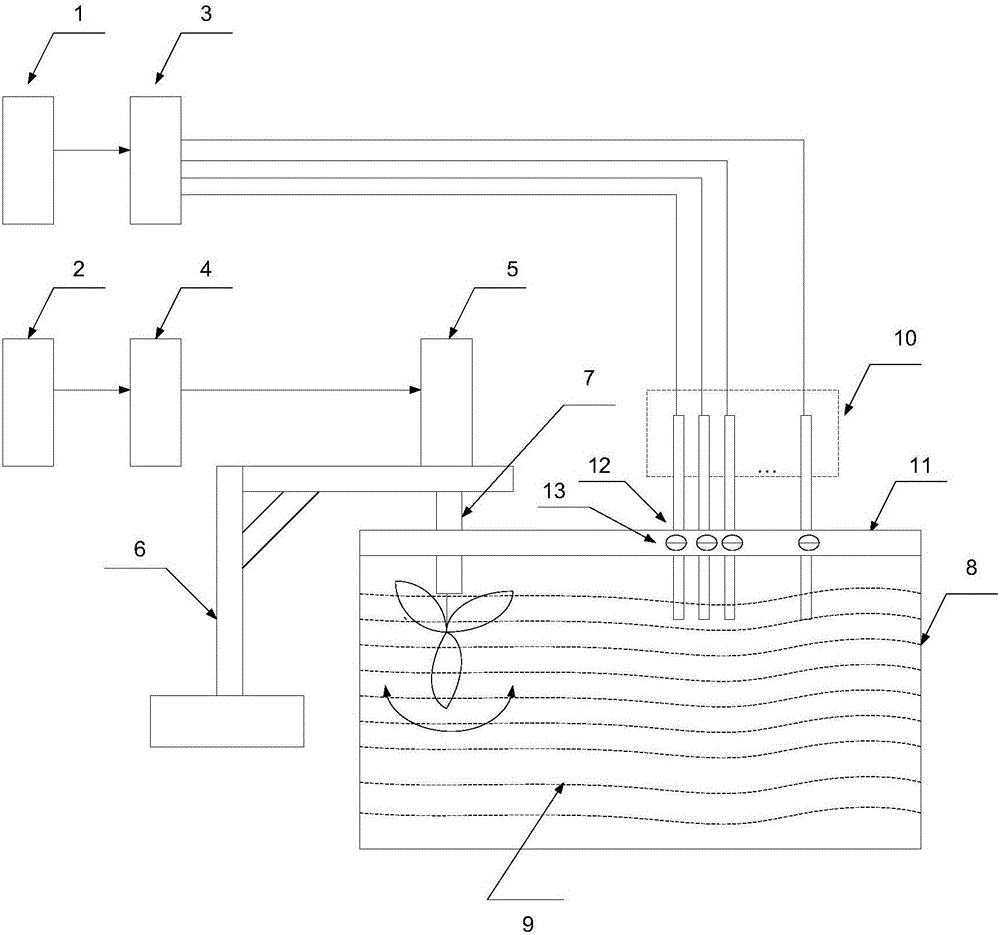

[0020] figure 1 It is a system framework diagram implemented by the temperature sensor consistency test device of the present invention. by figure 1 It can be seen that the temperature sensor consistency test device of the present invention includes a host computer 1, a motion controller 2, a data acquisition card 3, a motor driver 4, a motor 5, a motor bracket 6, a motion actuator 7, and a liquid tank 8 filled with liquid 9. , The temperature sensor 10 to be measured and the fixture 11; the host computer 1 communicates with the data acquisition card 3, the control port of the data acquisition card 3 is connected to the temperature sensor 10, and the motion control The motor 2 is connected to the motor driver 4, and the output end of the motor driver 4 is connected to the motor 5; the motor 5 is fixed on the motor support 6 and makes the motor 5 Located above the liquid tank 8, the motor 5 is connected to one end of the motion actuator 7 through a coupling. The page 3 paddle ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap