A kind of preparation method of oil resistant flame retardant cable material

A flame-retardant cable material and oil-resistant technology, which is applied in the direction of circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problems of poor compatibility between ammonium polyphosphate and organic materials, and cannot fully meet the mechanical performance requirements. Achieve structural stability, improve oil resistance, and increase compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

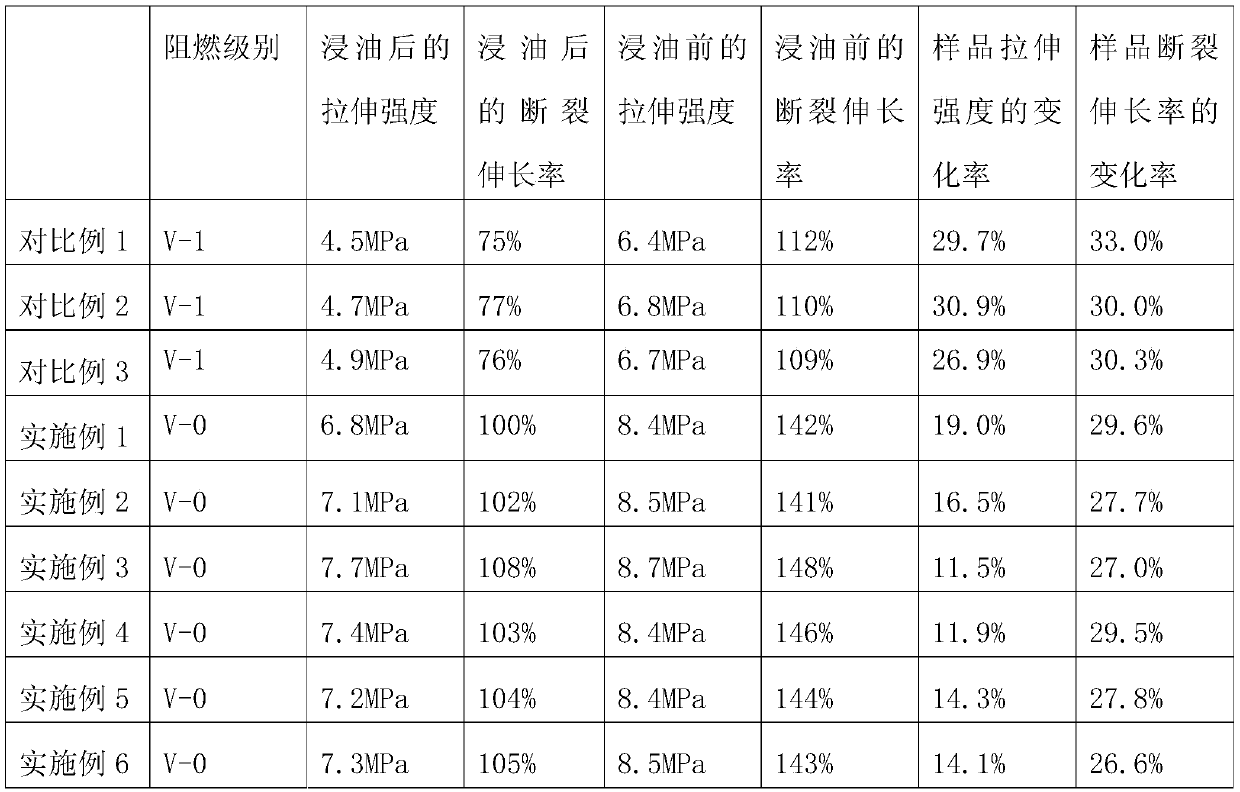

Examples

Embodiment 1

[0038] 1. Preliminary preparation:

[0039] Preparation of the mixed organic solvent: in parts by weight, 10 parts of n-butylmercaptan, 12 parts of fullerenol and 30 parts of deionized water were mixed and stirred evenly to obtain the mixed organic solvent.

[0040] Preparation of soaked EPDM rubber: In parts by weight, 10 parts of acetone and 25 parts of diethylene glycol were mixed, added to EPDM rubber and soaked for 24 hours to obtain soaked EPDM rubber.

[0041] Preparation of oil-resistant elastomer: In parts by weight, heat up the internal mixer to 160°C, then add 5 parts of carbonyl iron, 8 parts of supercritical carbon dioxide and 3 parts of peroxide to 100 parts of soaked EPDM rubber After the lauroyl is mixed, put it into the internal mixer, and after internal mixing at a speed of 60r / min for 20 minutes, cut the knife 3 times on the left and right, make the triangle bag 8 times, and then release the slices. °C and a pressure of 10 MPa for 10 minutes to obtain an oi...

Embodiment 2

[0048] 1. Preliminary preparation:

[0049] Preparation of the mixed organic solvent: in parts by weight, 10 parts of n-butyl mercaptan, 13 parts of fullerenol and 37 parts of deionized water were mixed and stirred evenly to obtain the mixed organic solvent.

[0050] Preparation of soaked EPDM rubber: In parts by weight, 10 parts of acetone and 27 parts of diethylene glycol were mixed, added to EPDM rubber and soaked for 42 hours to obtain soaked EPDM rubber.

[0051] Preparation of oil-resistant elastomer: In parts by weight, the temperature of the internal mixer is raised to 175°C, and then 6 parts of carbonyl iron, 10 parts of supercritical carbon dioxide and 2 parts of isopropyl are added to 130 parts of soaked EPDM rubber Benzene hydrogen peroxide and 2 parts of dicyclohexyl peroxydicarbonate are mixed and put into the internal mixer. After banburying at a speed of 70r / min for 24 minutes, the left and right cutters are cut 4 times, and the thin triangle bag is beaten 9 ti...

Embodiment 3

[0058] 1. Preliminary preparation:

[0059] Preparation of the mixed organic solvent: in parts by weight, 10 parts of n-butyl mercaptan, 14 parts of fullerenol and 40 parts of deionized water were mixed and stirred evenly to obtain the mixed organic solvent.

[0060] Preparation of soaked EPDM rubber: In parts by weight, 10 parts of acetone and 27 parts of diethylene glycol were mixed, added to EPDM rubber and soaked for 36 hours to obtain soaked EPDM rubber.

[0061] Preparation of oil-resistant elastomer: by weight parts, the internal mixer is heated up to 167 ° C, and then 8 parts of carbonyl iron, 11 parts of supercritical carbon dioxide and 5 parts of initiator are added to 145 parts of soaked EPDM rubber Mix cyclohexanone peroxide and put it into the internal mixer, after internal mixing at a speed of 74r / min for 23 minutes, cut the left and right knives 3 times, make the triangular bag 9 times with thin tongs, and then release the slices. The temperature is 172°C and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com