A kind of preparation method of composite carbon material

A composite carbon and carbonization technology, which is applied in the preparation of composite carbon materials and the preparation of carbon functional materials combined with zeolite, can solve the problems of single function of carbon materials, difficulty in combination, and low added value, so as to improve carbonization efficiency and increase thermal efficiency. value, saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

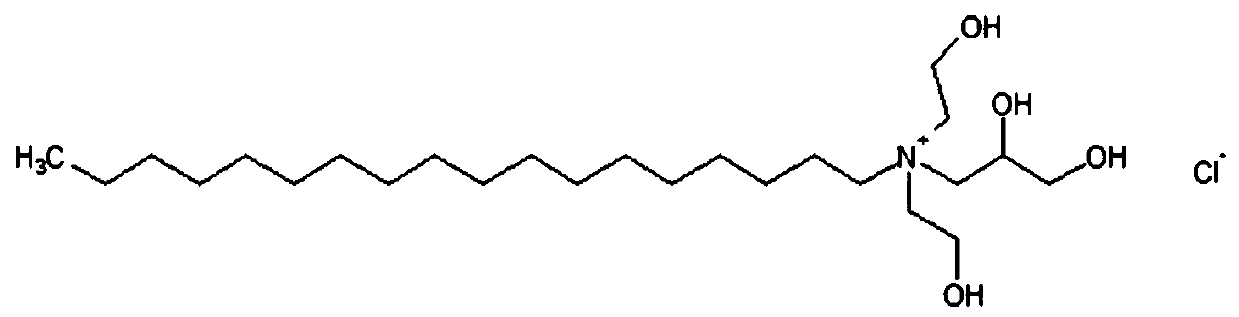

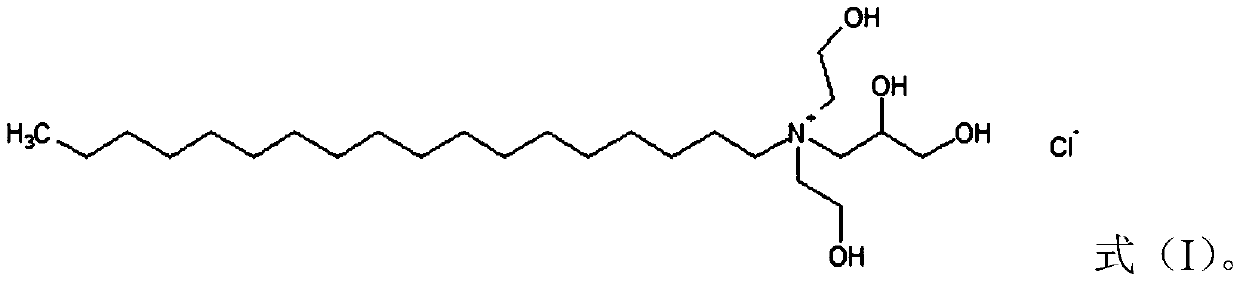

[0037] Take cotton stalks from Nanle, Henan, remove the leaves and husks of the stalks, smash them, and mix them with natural clinoptilolite (from Zhejiang Shenshi Mining Co., Ltd.) to prepare carbonized raw materials. The quality of the straw and clinoptilolite is The ratio is 6:1. Soak the carbonized raw material in a 0.3mol / L nitric acid solution at 50℃ for 2h, filter the carbonized raw material after soaking, filter out the nitric acid solution, and then place it in a carbonization container with a temperature of 400℃. Heated for 6h, then cooled to room temperature, washed thoroughly with 0.05mol / L aqueous solution of 2,3-dihydroxypropyl bishydroxyethyl stearyl ammonium chloride, then washed with distilled water to neutrality, and dried , That is, composite carbon material.

Embodiment 2

[0039] The hydrogenation catalyst was prepared using the composite carbon material of Example 1. The upgrading catalyst used was Ni-Cu / composite carbon material, where the molar ratio of Ni to Cu was 1:1, based on the total weight of the catalyst, the catalytically active group of Ni-Cu The content of hydrogenation is 5%, the hydrogenation raw material is bio-oil from kitchen waste (obtained from Guangzhou Fufei Chemical Co., Ltd.), and the hydrogenation upgrading conditions are 250°C, 8.0MPa hydrogen pressure, 2h. After testing, the oxygen content of the hydro-upgraded bio-oil was 6.2wt.%, and the catalyst life was about 860h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com