Applications of composite anode plate in zinc electrolysis

A technology of composite anode and zinc electrolysis, which is applied in the field of metallurgy to achieve the effects of not being easy to achieve strength, improving excellent conductivity, and shortening the distance between homopolar electrodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

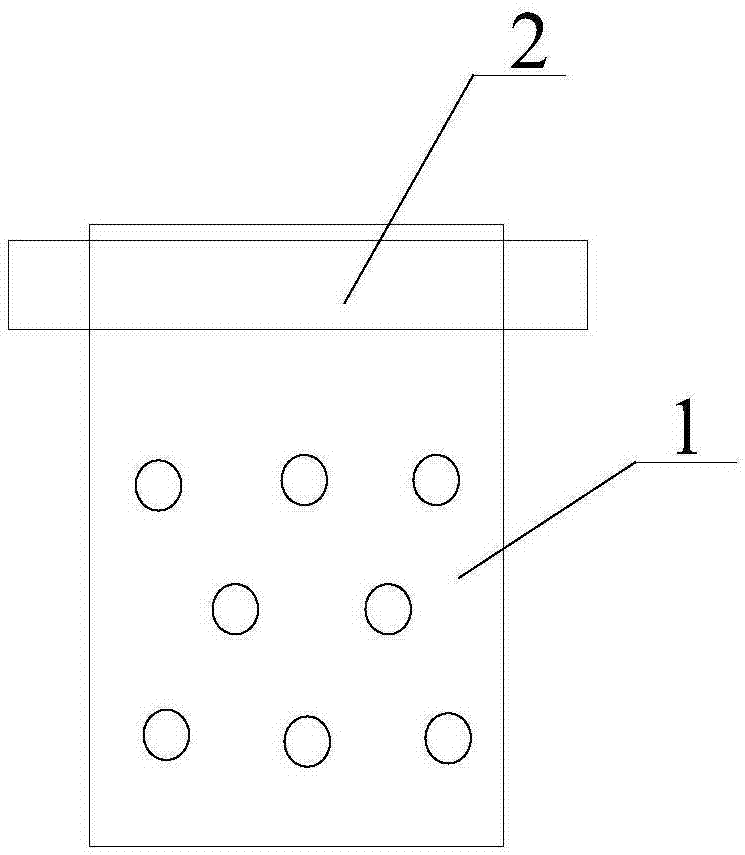

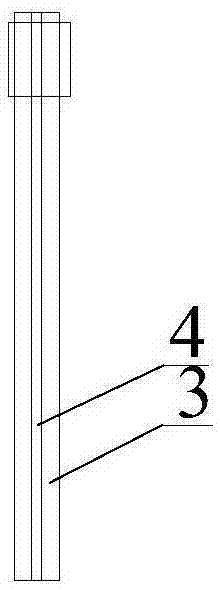

Image

Examples

Embodiment 1

[0026] The middle layer of the three-layer board is an aluminum sheet, and the two sides are lead plates. The three-layer board is made by embedded pressing composite method. The thickness of the aluminum sheet is 0.5mm, and the thickness of the lead plate is 3mm.

[0027] During zinc electrolytic deposition, put the above-mentioned anode plate and cathode plate that meet the specifications of the electrolytic cell together into the electrolytic cell that has been equipped with a conductive copper or aluminum row DC power supply system, and pump a zinc-rich solution containing 60g / L of zinc ions After energizing, under the action of strong current, the current passes through the conductive electrode of the anode plate, so that zinc ions are precipitated from the cathode and attached to the cathode plate, and the new solution is replenished by leaching, clarification, and filtering to remove impurities and enrich the content of zinc solution, and replenish new After the liquid i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap