Preparation method of slow-release polycarboxylic acid water reducing agent

A technology of slow-release polycarboxylic acid and water reducing agent, which is applied in the field of preparation of slow-release polycarboxylic acid water reducing agent, can solve the problems of low system activity and narrow application range, and can meet the requirements of normal temperature polymerization and better effect. , the effect of wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

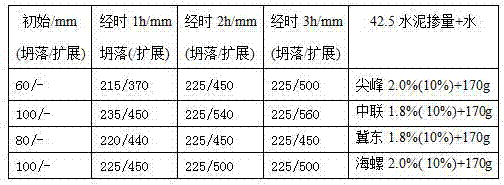

[0021] Embodiment 1, a kind of preparation method of slow-release polycarboxylate superplasticizer, its steps are as follows:

[0022] (1) Prepare 1# dropping solution: Mix acrylic acid, acrylate and deionized water to obtain an aqueous solution with a mass percentage of 55%-65%, where the mass ratio between acrylic acid, acrylate and deionized water is 72: 464:288;

[0023] (2) Preparation of 2# dripping liquid: Mix reducing agent, chain transfer agent, 30% liquid alkali and deionized water to prepare an aqueous solution with a mass percentage of 5%-10%, of which reducing agent, chain transfer agent, 30% The mass ratio between liquid caustic soda and deionized water is 5:15:15:470;

[0024] (3) Add deionized water to the enamel reaction kettle equipped with a thermometer, agitator, double dropping pipe and reflux condenser, start stirring, put in polycarboxylic acid macromonomer, and add maleic acid ester and concentrated sulfuric acid to accelerate The polycarboxylate macr...

Example Embodiment

[0025] Embodiment 2, a kind of preparation method of slow-release polycarboxylate superplasticizer, its steps are as follows:

[0026] (1) Prepare 1# dropping solution: Mix acrylic acid, acrylate and deionized water to obtain an aqueous solution with a mass percentage of 55%-65%, where the mass ratio between acrylic acid, acrylate and deionized water is 180: 650: 447;

[0027] (2) Preparation of 2# dripping liquid: Mix reducing agent, chain transfer agent, 30% liquid alkali and deionized water to prepare an aqueous solution with a mass percentage of 5%-10%, of which reducing agent, chain transfer agent, 30% The mass ratio between liquid alkali and deionized water is 10: 30: 30: 950;

[0028] (3) Add deionized water to the enamel reaction kettle equipped with a thermometer, agitator, double dropping pipe and reflux condenser, start stirring, put in polycarboxylic acid macromonomer, and add maleic acid ester and concentrated sulfuric acid to accelerate The polycarboxylate macr...

Example Embodiment

[0029] Embodiment 3, in the preparation method of the slow-release polycarboxylate superplasticizer described in embodiment 1 and 2: acrylate is methyl acrylate, butyl acrylate, ethyl acrylate, hydroxyethyl acrylate, hydroxypropyl acrylate one or more of.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap