A feeder and its processing technology

A feeder and blanking technology, which is applied in animal husbandry, poultry industry, applications, etc., can solve the problem of damage to the blanking bucket and base, material leakage, direct action on the base or poultry may be pecked on the blanking bucket, etc. problem, to achieve the effect of avoiding waste, uniform blanking and sufficient blanking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

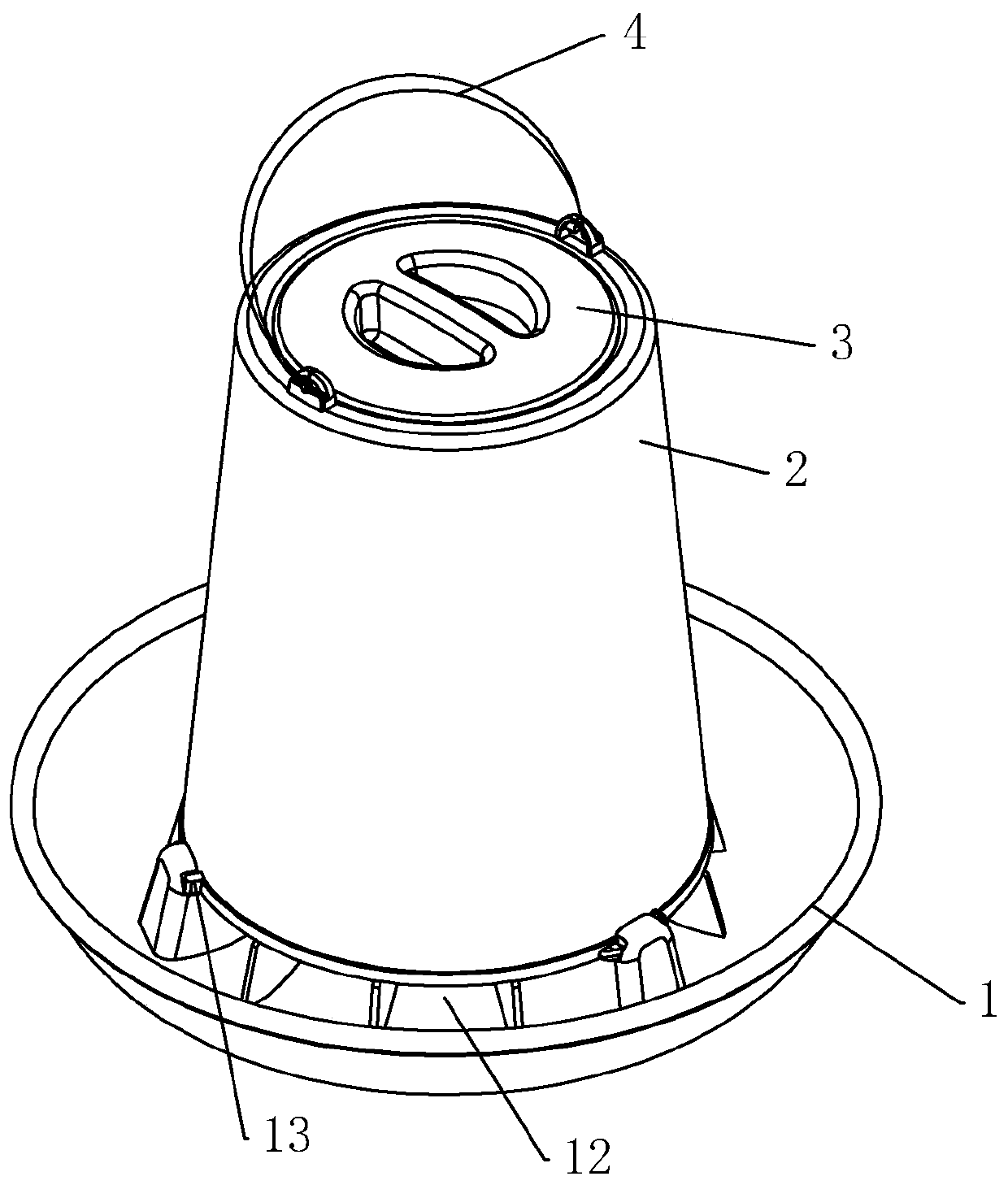

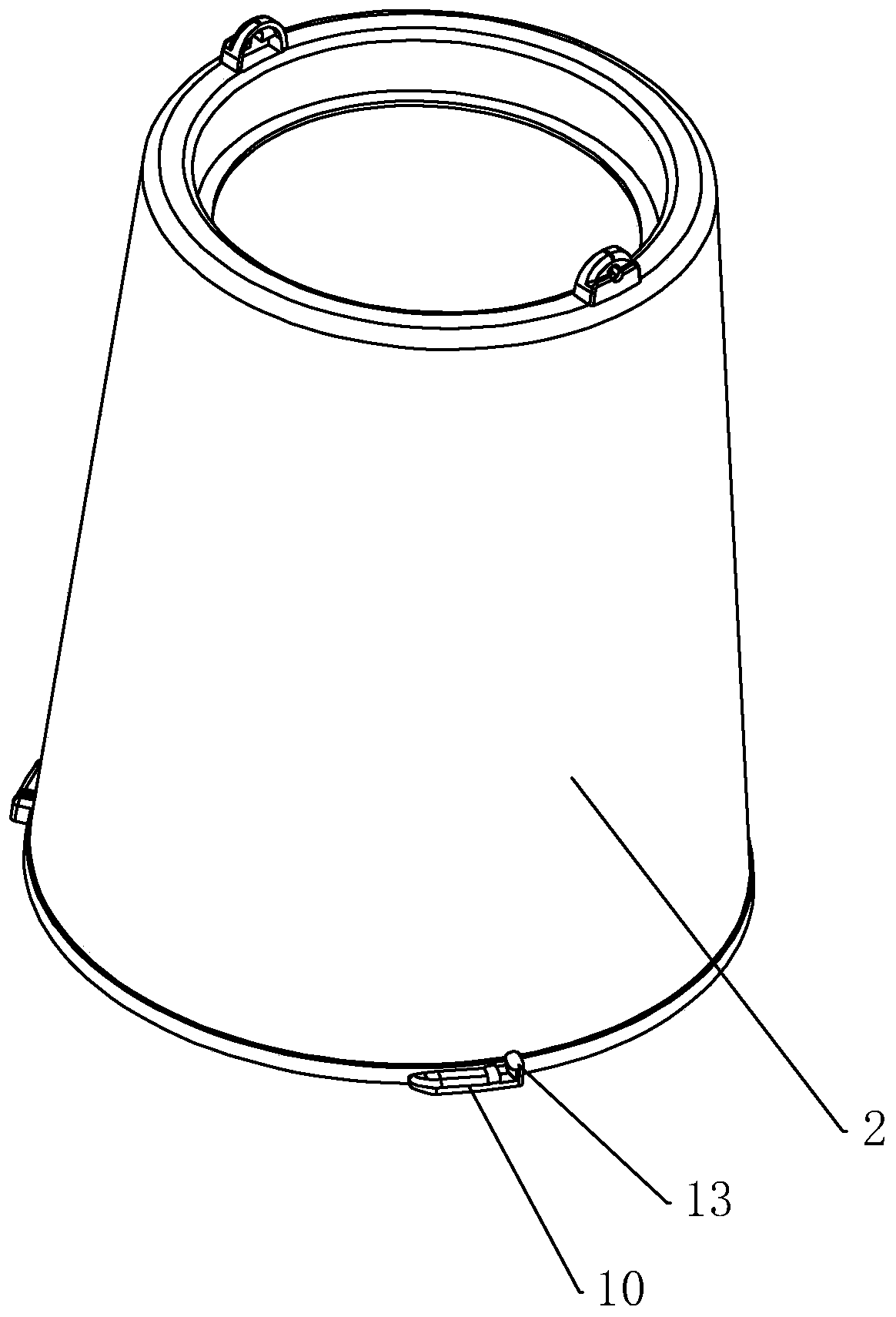

[0036] a feeder such as figure 1 As shown, it includes a base 1 and a blanking bucket 2 installed on the base 1, and also includes a lid 3 with a cover on the blanking bucket 2, a handle 4 arranged on the upper end of the blanking bucket 2, and the lid 3 is opened during use. The feed is poured into the dosing bucket 2 through the upper end of the dosing bucket 2, and then some feed will fall on the base 1 in the dosing bucket 2, and then the poultry can eat the feed on the base 1.

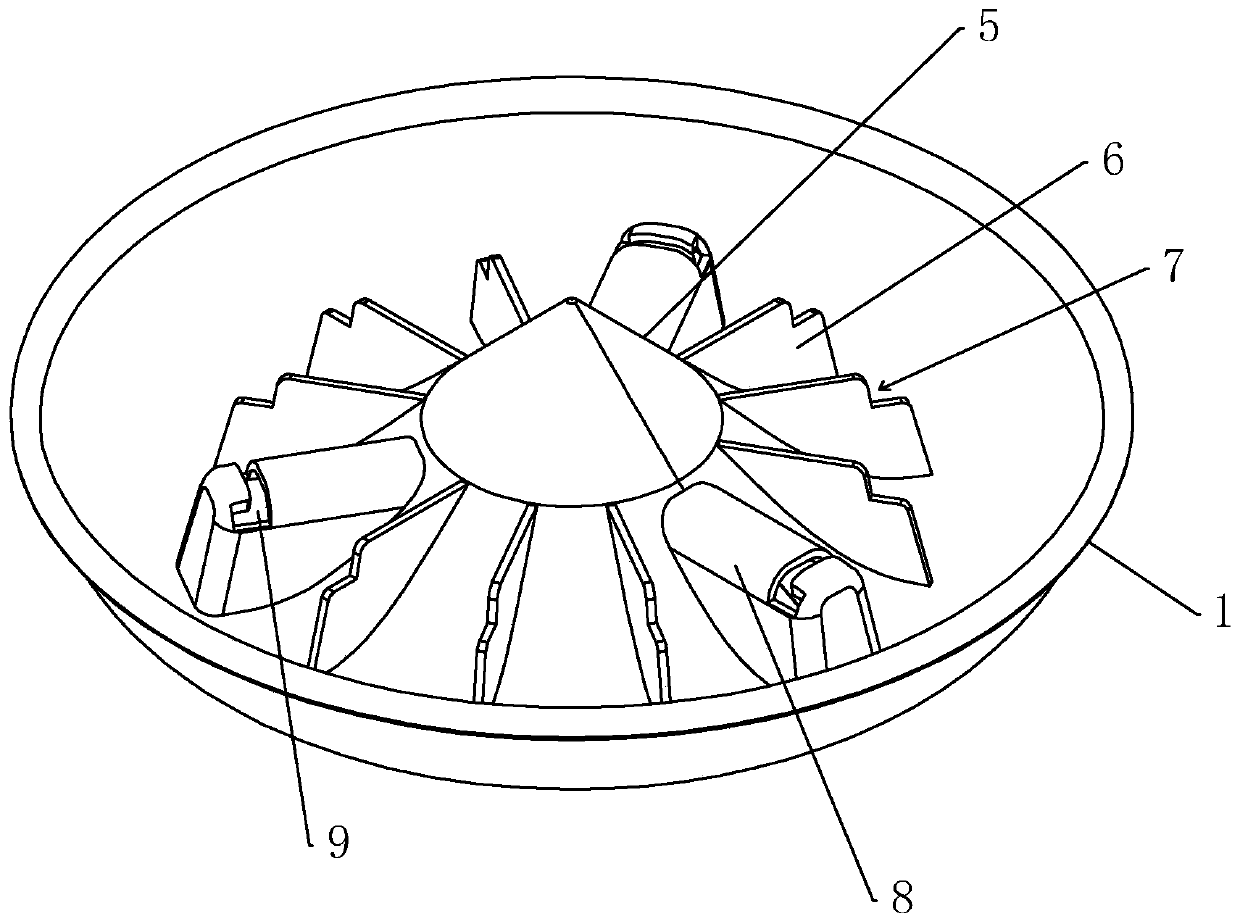

[0037] like Figure 2-4 As shown, the center of the base 1 is provided with a coaxial conical blanking protrusion 5, and between the lower side of the blanking protrusion 5 and the base 1, there are several evenly distributed distribution grids 6, and the distribution grid 6 A notch 7 is provided on the upper edge of the base away from the center of the base 1, and an installation card seat 8 is provided between two adjacent material distribution grids 6, and an L-shaped installation card slot 9 ...

Embodiment 2

[0042] A kind of feeder, the difference between embodiment 2 and embodiment 1 is that the base 1 and the drop bucket 2 are different in components, the base 1 and the drop bucket 2 include the following components by weight, 70 parts of polypropylene, 10 parts by weight 1 part of polypropylene copolymer, 1 part of nano calcium carbonate whisker, 1 part of POE resin, 1 part of PC.

Embodiment 3

[0044] A kind of feeder, the difference between embodiment 3 and embodiment 1 is that the components and contents of the base 1 and the dropping bucket 2 are different, the base 1 and the dropping bucket 2 include the following components by weight, 60 parts poly Propylene, 30 parts of copolymerized polypropylene, 1 part of silicon carbide nano whiskers, 1 part of PET resin, 1 part of PC.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com