Technology and equipment for drying alfalfa under combination of gas jet impacting and normal-temperature ventilating

A gas jet, drying process technology, applied in dryer combination, drying gas arrangement, progressive dryer and other directions, can solve the problems of serious leaf loss, high loss of nutrients, low processing capacity, etc., to reduce the cost of mechanical drying, Improves consistency, reduces drying temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0088] Example

[0089] a) Start the first central control box 8. After the preheating is completed, spread the cut and flattened alfalfa raw materials on the conveyor belt 2 through the distributor 1 and make them pass through the high temperature drying chamber 5 at a uniform speed; It is 5cm.

[0090] The alfalfa raw material origin is Baotou, Inner Mongolia.

[0091] b) When the alfalfa raw material passes through the high-temperature drying chamber 5, the first stage of high-temperature drying is performed.

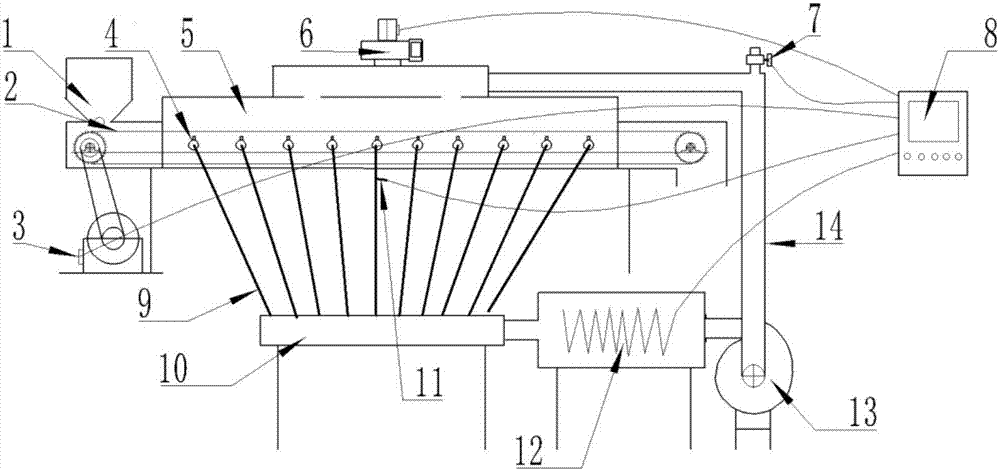

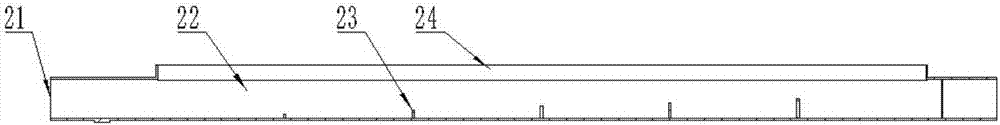

[0092] During the drying process, the gas in the high-temperature drying chamber 5 enters the electric heating box 12 through the return air pipe 14 under the pressurization of the high-pressure fan 13, and then enters the slit-type air flow impact through the air distribution box 10 and the air duct 9 in turn. The pipe 4 is sprayed into the high-temperature drying chamber 5 through the airflow nozzle 24 to realize the circulating heating of the alfalfa raw materials and at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap