Air vent device and electronic device employing same

A technology of tuyere device and electronic device, which is applied in the direction of electrical equipment casing/cabinet/drawer, electrical components, casing/cabinet/drawer parts, etc., and can solve the problem of non-replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

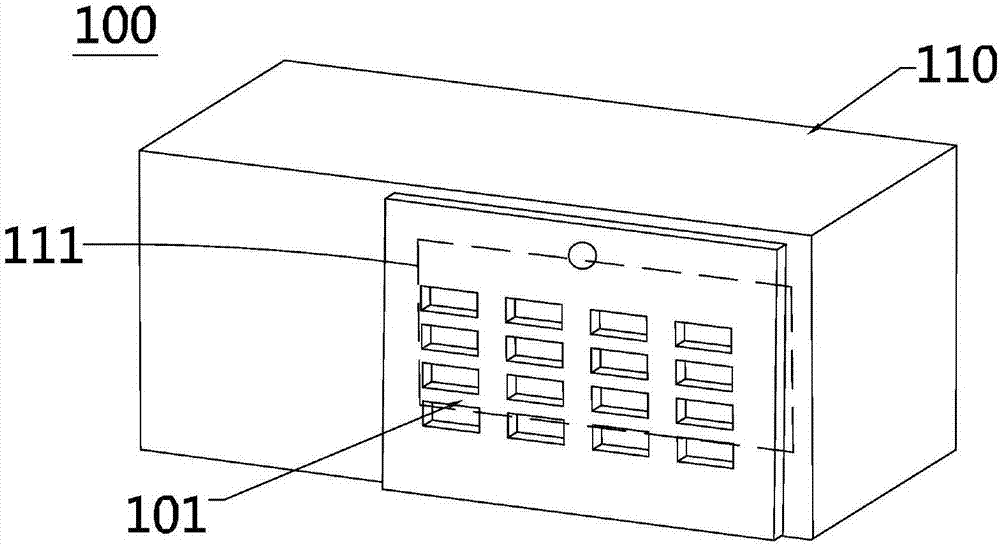

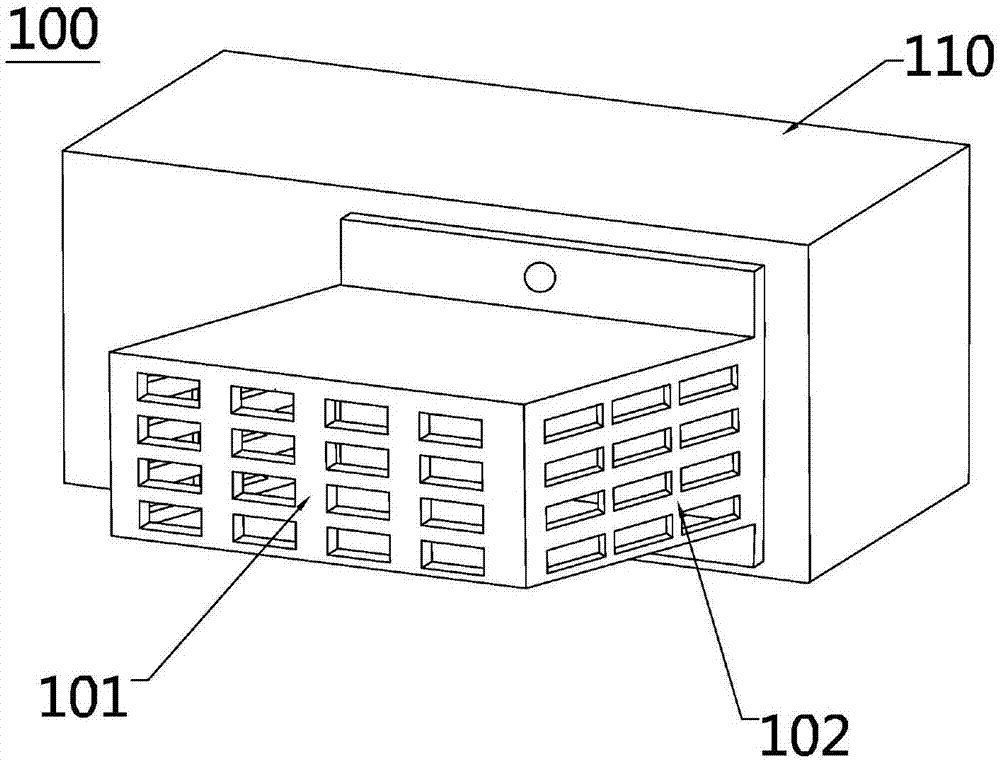

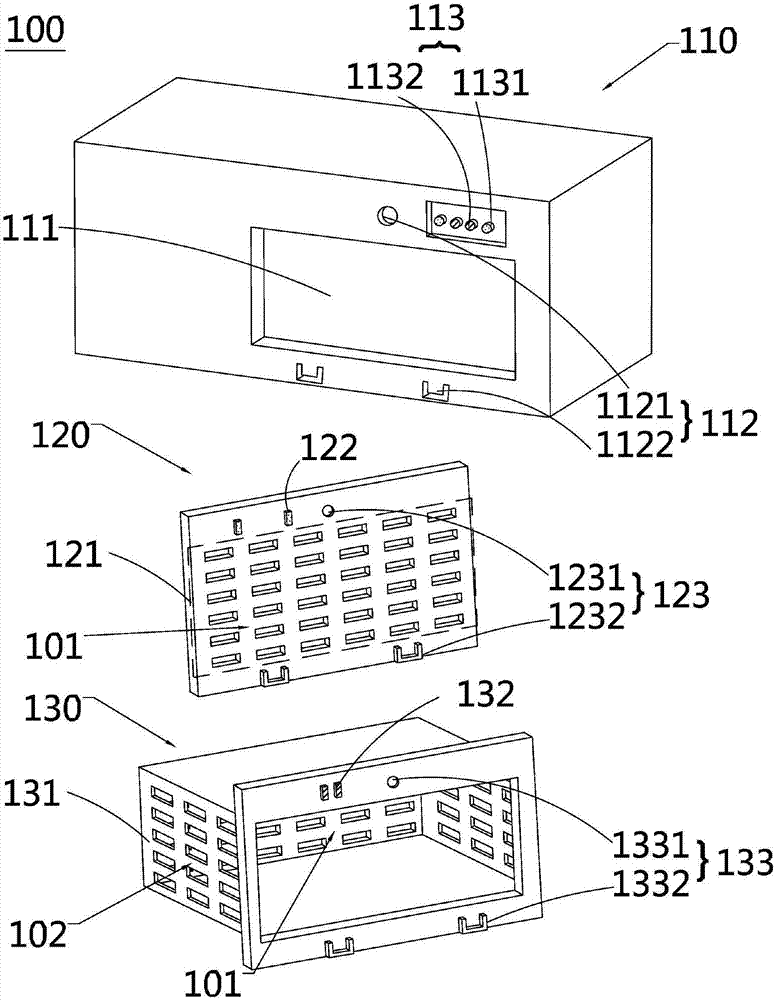

[0032] figure 1 is a schematic diagram of the tuyere device of the present invention in the first mode, figure 2 It is a schematic diagram of the tuyere device of the present invention in the second mode. Please also refer to figure 1 , figure 2 The tuyere device 100 includes a body unit 110 and a cover unit (not shown), the body unit 110 has a tuyere 111, the cover unit includes at least one sub-cover unit each having a ventilation hole, at least one sub-cover unit has a first sub cover unit 101, such as figure 1 , figure 2 As shown, the first sub-cover unit 101 faces the air outlet 111 when in use. Wherein, the tuyere device 100 has a first mode and a second mode. In the first mode, only the first sub-cover unit 101 is used for ventilation of the tuyere 111; in the second mode, at least one sub-cover unit also has a second mode. Two sub-cover units 102, the first sub-cover unit 101 and the second sub-cover unit 102 are used for the ventilation of the tuyere 111 toge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com