Arc glass cleaning plant

A technology for cleaning device and curved glass, applied in the direction of cleaning flexible articles, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of film release, glass with multiple pinholes, etc., to reduce glass demoulding and improve efficiency , the effect of reducing the difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

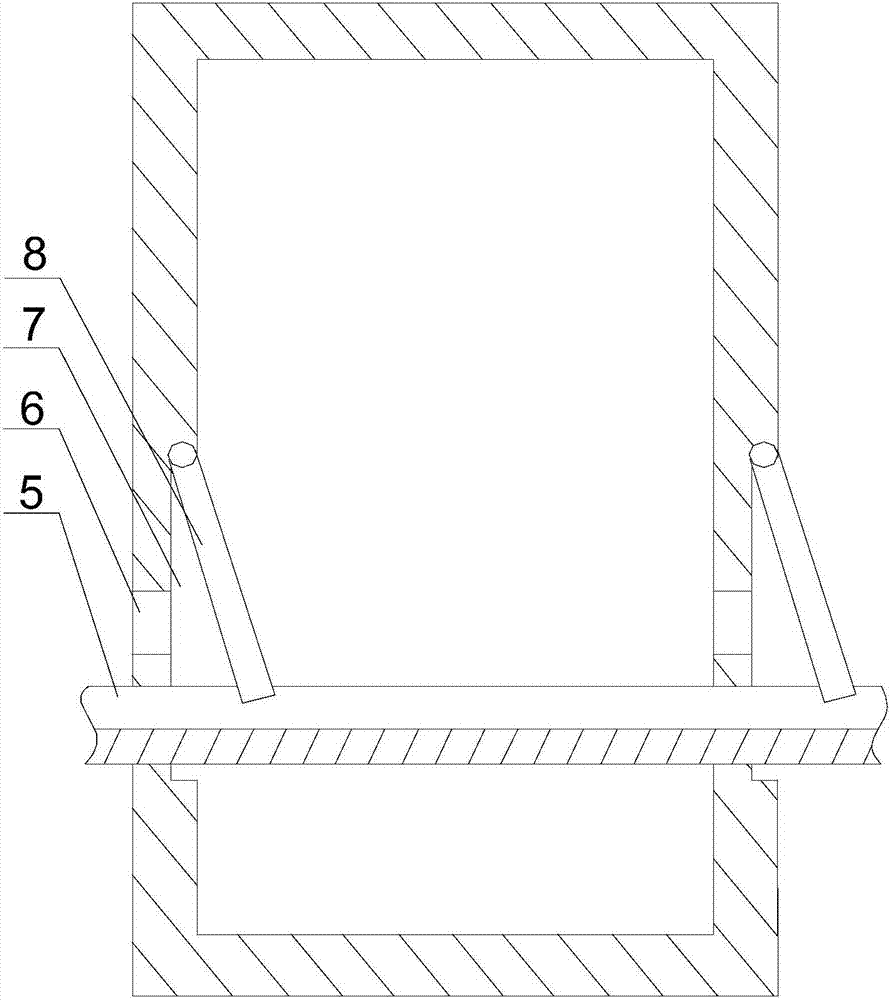

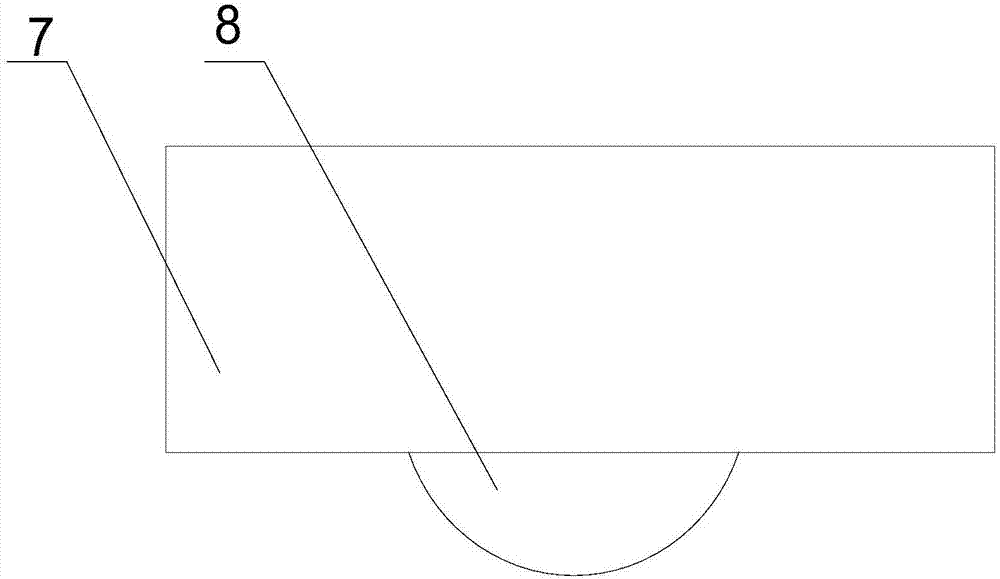

[0021] Such as Figure 1 to Figure 3 As shown, this embodiment includes a transmission frame 4 and an adsorption cavity 1 installed on the transmission frame 4. The top of the adsorption cavity 1 is installed with an adsorption hose 2 communicating with the interior. The end is provided with an arc-shaped hole 3 for the passage of curved glass, and an arc-shaped groove 5 is fixed at the arc top of the lower end of the arc-shaped hole 3, and the arc-shaped groove 5 runs through the entire adsorption cavity 1. 1 is provided with a groove 6 on the inner wall of the front end and the outer wall of the rear end thereof, and a baffle plate 7 is hingedly arranged on the upper end of the groove 6; The raised 8.

[0022] When working, the curved glass is placed in the arc-shaped groove 5 and moved to the arc-shaped hole 3. After the curved glass enters the adsorption chamber 1 through the arc-shaped hole 3, the cleaning agent or drying is passed through the adsorption hose 2. After t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com