Graphene-functionalized polyphenyl ether/nylon 6 composite material and preparation method

A composite material and nanocomposite material technology, applied in the field of graphene functionalized polyphenylene ether/nylon 6 composite material and preparation, can solve the problems of poor heat resistance, poor organic solvent resistance, poor dimensional stability, etc. The effect of performance, simple operation process and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

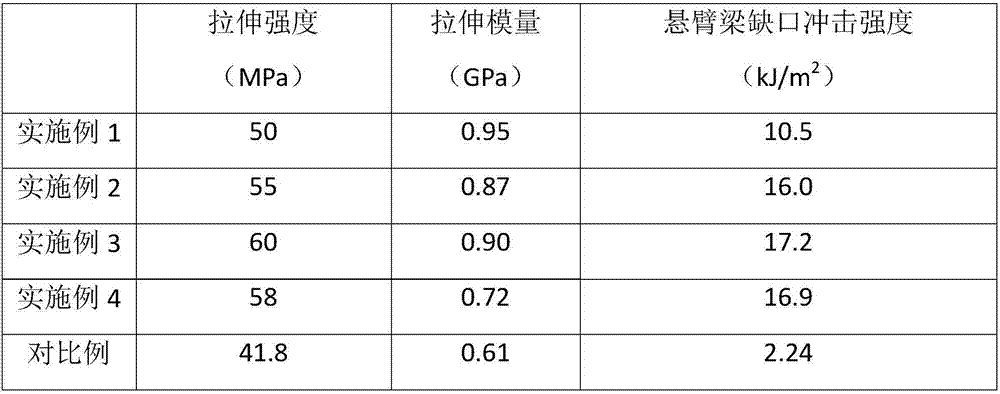

[0018] The graphene-functionalized polyphenylene ether / nylon 6 composite material prepared in the present invention adopts ASTM standard injection molding, and the injection molding machine performs injection molding under the condition of 250-285°C.

[0019] Mechanical property test method:

[0020] 1. Tensile performance: tested according to GB / T1040-2006 standard, the tensile speed is 50mm / min;

[0021] 2. Bending performance: according to the CB / T9341-2008 standard test, the bending speed is 2mm / min;

[0022] 3. Izod notched impact strength: tested according to GB / T1843-2008 standard.

[0023] After the sample is formed, it is placed in a standard environment with a temperature of 23±2°C and a humidity of 50±5% for 88 hours before testing. The test environment is a temperature of 23±2°C and a humidity of 50±5%.

Embodiment 1

[0026] (1) Add 0.1 part by mass of modified graphene with a lateral dimension greater than 3 μm and 1 part by mass of deionized water into 100 parts by mass of caprolactam melt, and stir and mix at 80° C. at high speed (300 rpm) to form a dispersion. The modified graphene is a single-layer graphene with oxygen-containing functional groups such as carboxyl and hydroxyl groups on the surface; the carbon-to-oxygen ratio is 2.5;

[0027] (2) Under the protection of nitrogen, the above dispersion liquid was heated to 250°C in the polycondensation reactor, and reacted at 0.5MPa for 3 hours; then reacted under vacuum for 4 hours to obtain a polymer melt; finally, the polymer melt The graphene / nylon 6 nanocomposite material is obtained through water-cooling granulation.

[0028] (3) polyphenylene ether, graphene / nylon 6 nanocomposite material and PPO-g-MAH are counted as 50:45:5 in parts by weight, premixed in a mixer to obtain a uniformly mixed premix;

[0029] (4) Using a twin-scre...

Embodiment 2

[0032] (1) Add 1 part by mass of modified graphene with a lateral dimension greater than 3 μm and 10 parts by mass of deionized water into 100 parts by mass of caprolactam melt, stir and mix at 80° C. at high speed (300 rpm) to form a dispersion. The modified graphene is a single-layer graphene with oxygen-containing functional groups such as carboxyl and hydroxyl groups on the surface; the carbon-to-oxygen ratio is 6;

[0033] (2) Under the protection of nitrogen, the above dispersion liquid was heated to 220°C in the polycondensation reactor, and reacted at 1MPa for 3 hours; then reacted under vacuum for 4 hours to obtain a polymer melt; finally, the polymer melt was passed through Water-cooled granulation to obtain graphene / nylon 6 nanocomposites.

[0034] (3) Premixing polyphenylene ether, graphene / nylon 6 nanocomposite material and PPO-g-MAH in a proportioning ratio of 50:40:10 in parts by weight in a mixer to obtain a uniformly mixed premix;

[0035] (4) Using a twin-sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com