Method of removing tin from sodium tungstate solution

A technology from sodium tungstate and sodium tungstate, applied in the field of tin removal from sodium tungstate solution, can solve the problems such as poor tin removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] A kind of method for removing tin from sodium tungstate solution provided by the invention comprises the following steps:

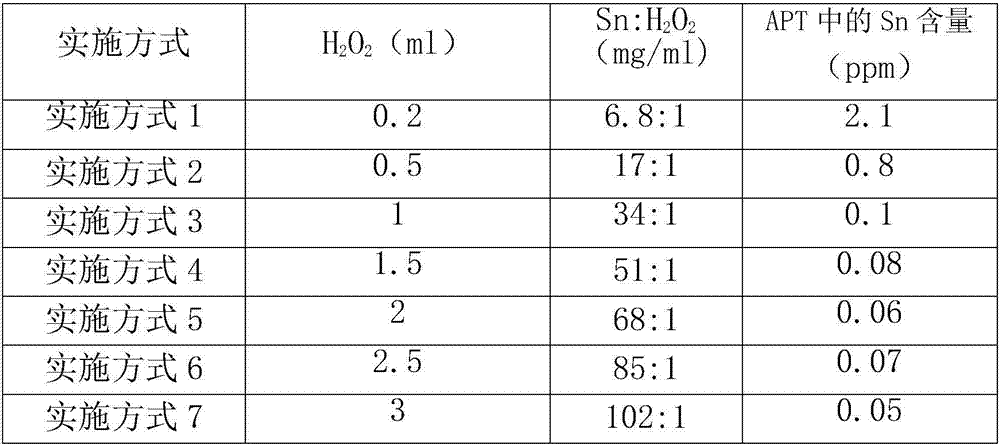

[0057] (1) Take 1000ml tin-containing sodium tungstate solution, wherein WO 3 The concentration of Sn is 132g / l, the concentration of Sn is 21mg / l, add 1ml of industrial hydrogen peroxide, slowly add sulfuric acid to adjust the alkalinity of sodium tungstate solution, maintain the alkalinity at 1.8g / l, the temperature is 35°C, and react for 30min to prepare Contains SnO 3 2- Sodium tungstate solution;

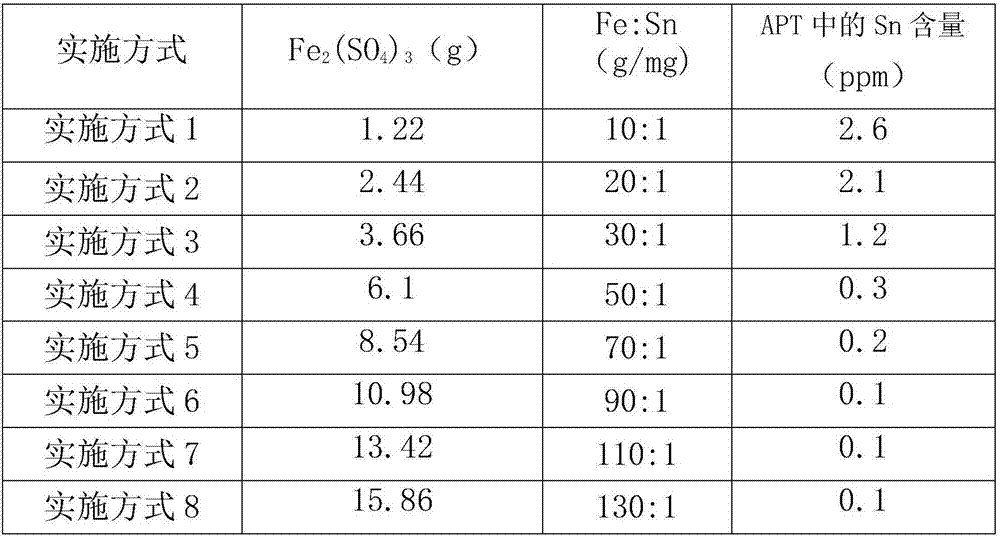

[0058] (2) the SnO containing SnO prepared in step (1) 3 2- First add 1.81g of ferric chloride to the sodium tungstate solution, the mass ratio of Fe to Sn is 30, then add sodium hydroxide, keep stirring, keep the temperature at 40°C, and react for 50min to make the tin in the sodium tungstate solution adsorb In the ferric hydroxide precipitate formed.

[0059] (3) finally the solid-liquid mixture containing ferric hydroxide precipitation that...

Embodiment 2

[0061] A kind of method for removing tin from sodium tungstate solution provided by the invention comprises the following steps:

[0062] (1) Take 1000ml tin-containing sodium tungstate solution, wherein WO 3 The concentration of Sn is 123g / l, the concentration of Sn is 34mg / l, add 1ml of industrial hydrogen peroxide, slowly add sulfuric acid to adjust the alkalinity of sodium tungstate solution, maintain the alkalinity at 2.0g / l, the temperature is 40°C, and react for 40min to prepare Contains SnO 3 2- Sodium tungstate solution;

[0063] (2) the SnO containing SnO prepared in step (1) 3 2- First add 6.1g of iron sulfate to the sodium tungstate solution, the mass ratio of Fe to Sn is 50, then add sodium hydroxide, keep stirring, keep the temperature at 60°C, and react for 50min to make the tin in the sodium tungstate solution adsorb on The resulting ferric hydroxide precipitates.

[0064] (3) finally the solid-liquid mixture containing ferric hydroxide precipitation that...

Embodiment 3

[0066] A kind of method for removing tin from sodium tungstate solution provided by the invention comprises the following steps:

[0067] (1) Take 1000ml tin-containing sodium tungstate solution, wherein WO 3 The concentration of Sn is 146g / l, the concentration of Sn is 41mg / l, adding 1ml of industrial hydrogen peroxide, slowly adding sulfuric acid to adjust the alkalinity of sodium tungstate solution, maintaining the alkalinity at 2.2g / l, the temperature is 45°C, and reacting for 40min to prepare Contains SnO 3 2- Sodium tungstate solution;

[0068] (2) the SnO containing SnO prepared in step (1) 3 2- Add 14.2g of ferric nitrate to the sodium tungstate solution, the mass ratio of Fe to Sn is 80, then add sodium hydroxide, keep stirring, keep the temperature at 60°C, and react for 50min to make the tin in the sodium tungstate solution adsorb on The resulting ferric hydroxide precipitates.

[0069] (3) finally the solid-liquid mixture containing ferric hydroxide precipita...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com