Roll feeding device for printing film production

A technology of roll feeding device and printing film, which is applied in the direction of winding strips, sending objects, transportation and packaging, etc. It can solve the problems of troublesome installation process, easy to be worn, and unfavorable production efficiency, so as to improve utilization rate and not easy to scratch Injury and manpower saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

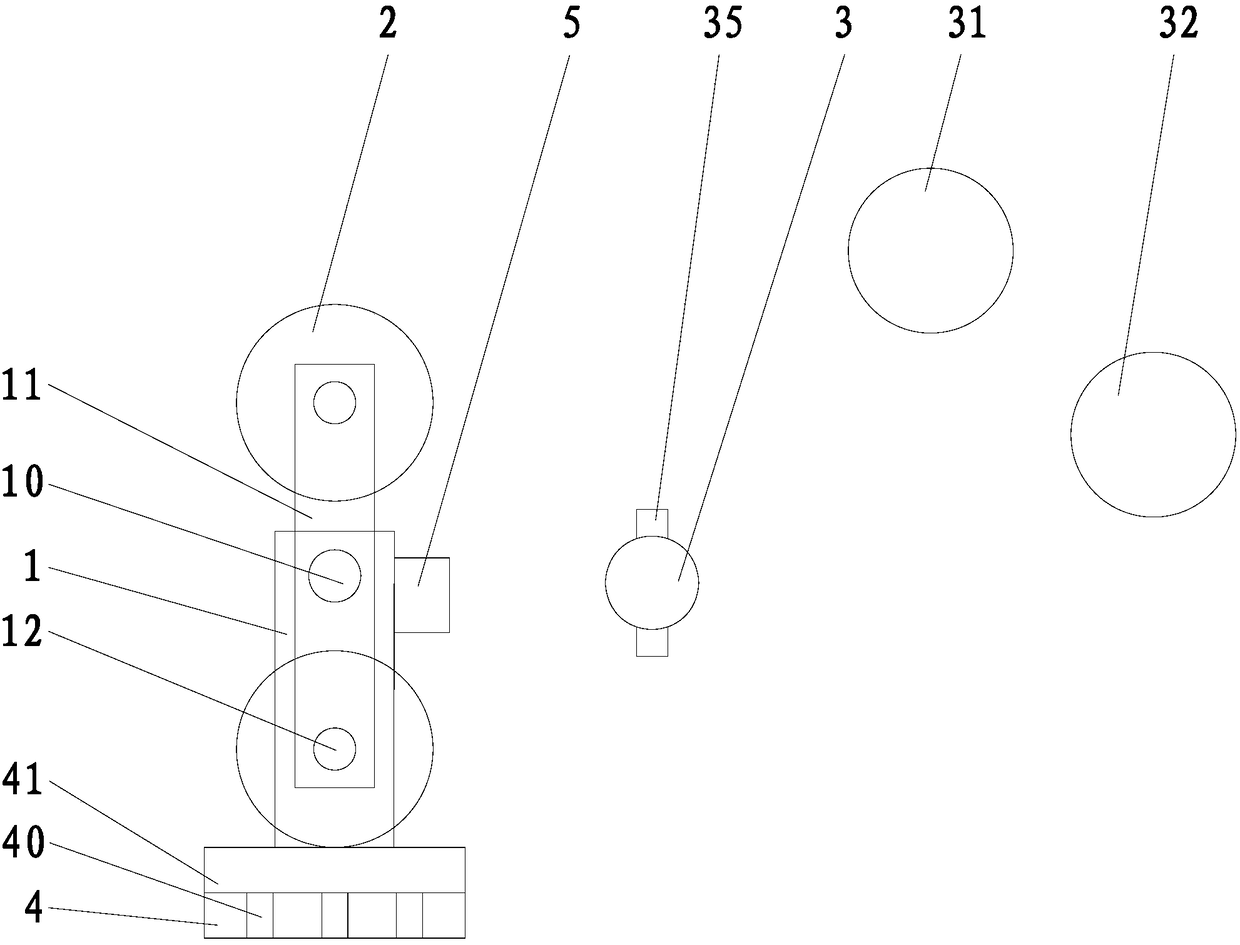

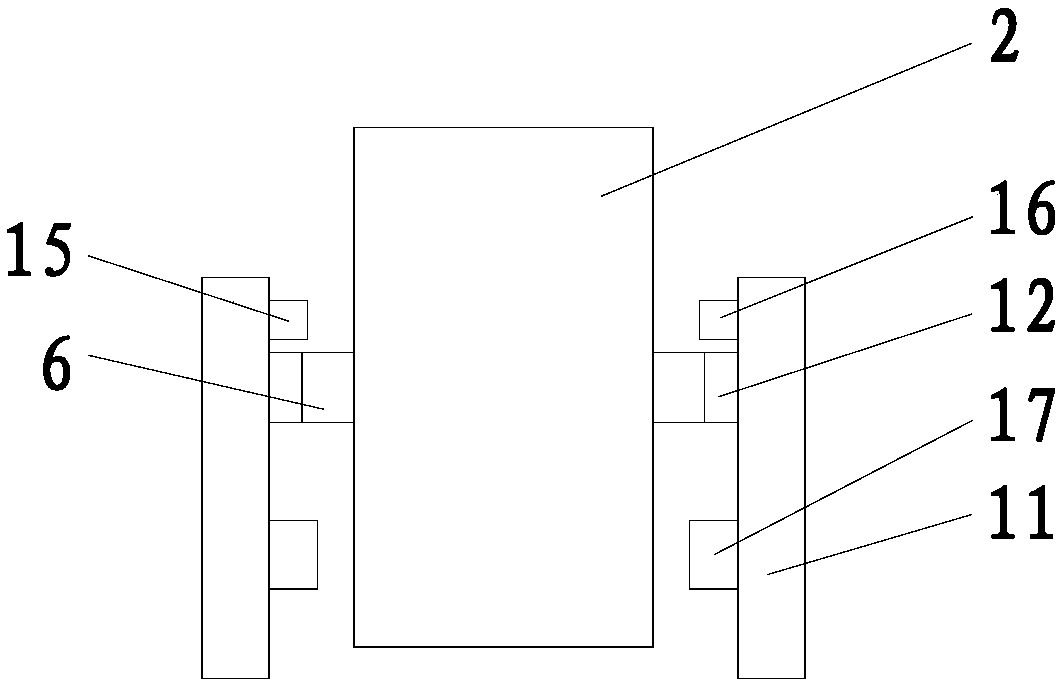

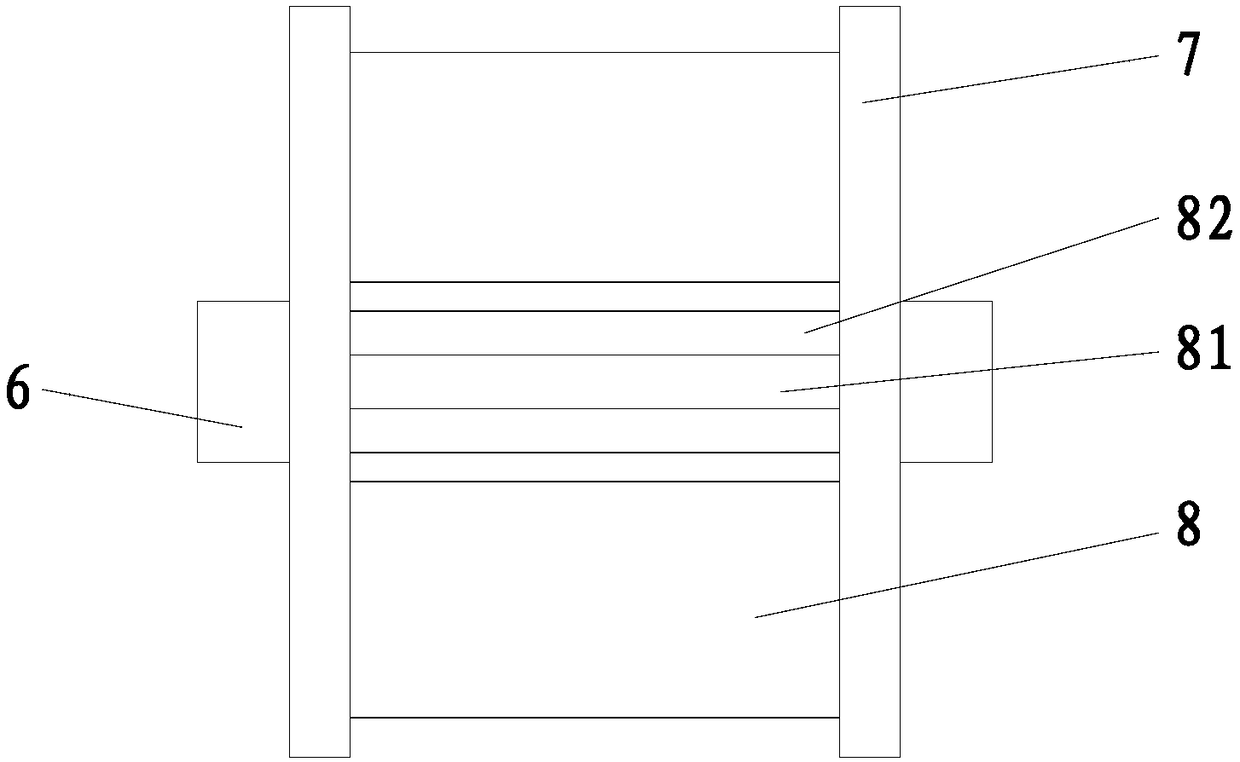

[0017] refer to figure 1 , figure 2 , image 3 and Figure 4 , a roll feeding device for printing film production in the present invention, comprising a film loading roll 2, a control device 5, a fixed frame 1 arranged in sequence, a locking shaft 3, a movable shaft 31 that can actively move up and down, and a fixed shaft 32. The frame 1 is equipped with two parallel vertical fixed plates 11, the fixed plate 11 is fixed on the fixed frame 1 through the first installation shaft 10 that can actively rotate, each fixed plate 11 is equipped with two active The rotating and telescopic second installation shaft 12 is installed between the two fixed plates 11, and two upper and lower film-loading rolls 2 are installed. The film-loading roll 2 is composed of a central shaft 6, a side baffle 7, and a protective cylinder 8. Both ends of the central shaft 6 are respectively connected to the second mounting shaft 12 on different fixing plates 11, and two side baffles 7 are installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com