Macromolecular slurry curing agent and preparation method thereof

A mud solidifying agent and polymer technology, which is applied in the field of polymer mud solidifying agent and its preparation, can solve the problems of inconspicuous on-site solidification effect of high water content mud, lack of system allocation of selection and mixing amount, consumption of mineral resources, etc. To achieve the effect of convenient mechanical stirring construction, good compactness and good water stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

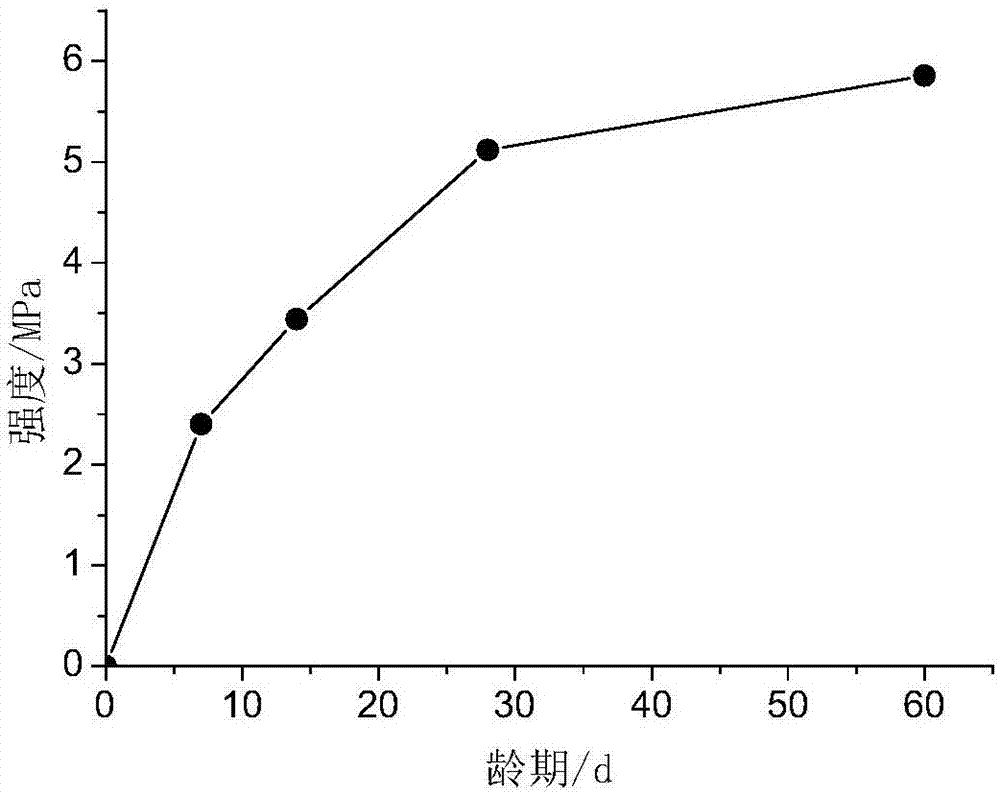

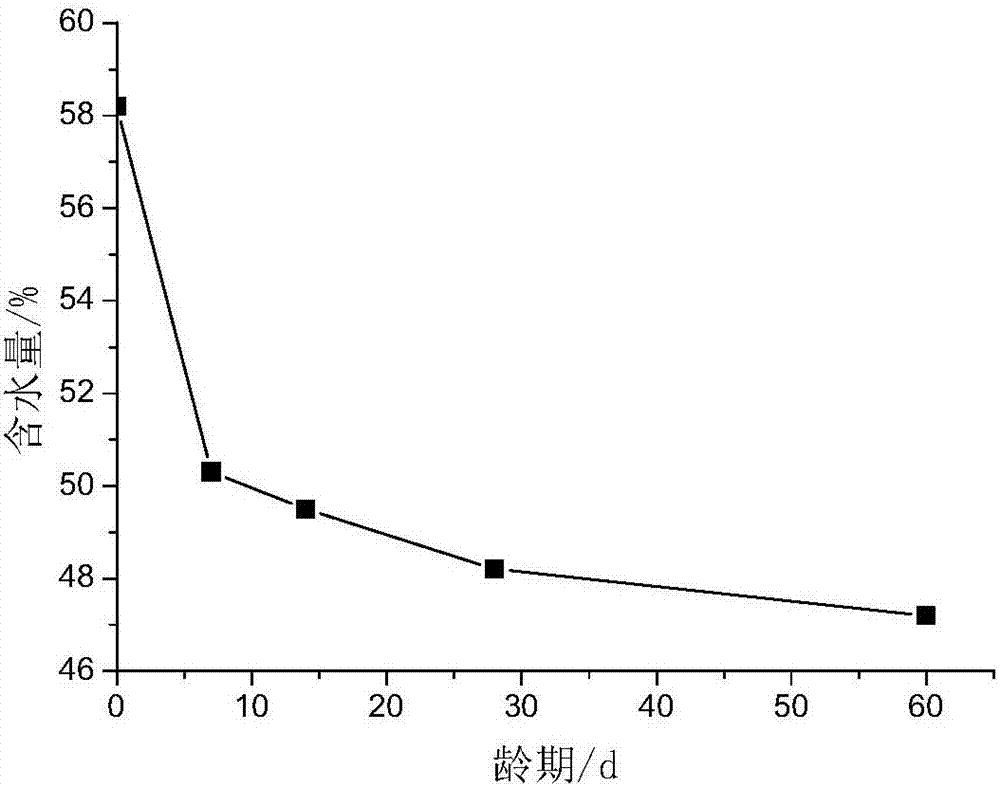

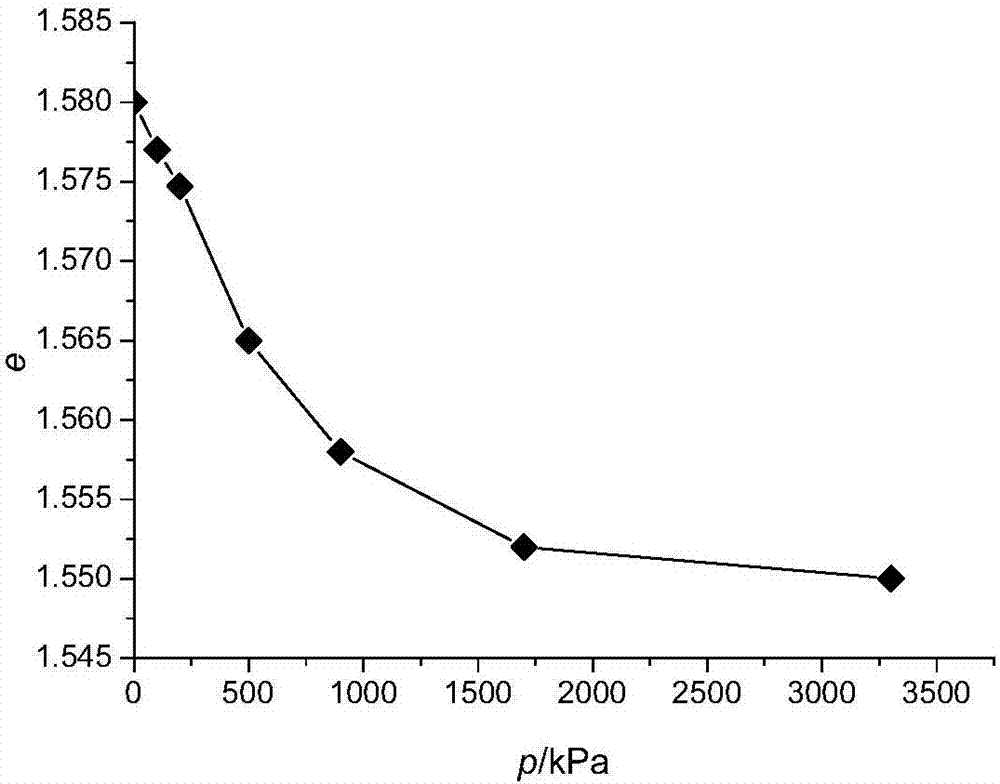

[0021] In order to make the technical means, creative features, goals and effects of the present invention easy to understand, the following examples will specifically illustrate the polymer mud curing agent of the present invention and its preparation method in conjunction with the accompanying drawings.

[0022] In step 1, fly ash, cement and quicklime are sequentially added into the mixer for sealing. In this embodiment, the fly ash is Class I high-calcium fly ash; the cement is 4.25 # Ordinary Portland cement; quicklime is in powder form, with a fineness of 120 mesh and a purity of over 98%. The manufacturer is Tianjin Zhiyuan Chemical Reagent Co., Ltd.

[0023] In step 2, the sealed stirrer was stirred at a low speed for 5 minutes, then stirred at a high speed for 10 minutes, and then stirred at a low speed for 5 minutes to obtain a mixture 1.

[0024] In step 3, the triethanolamine, polyacrylamide, polyvinyl alcohol and epoxy resin were placed in a low-temperature prote...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com