Preparation method and application of chitosan-ferrotitanium compound composite adsorbent

A compound, chitosan technology, applied in alkali metal compounds, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problems of low porosity and small surface area, achieve easy separation, increase adsorption capacity, and increase effective The effect of functional groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

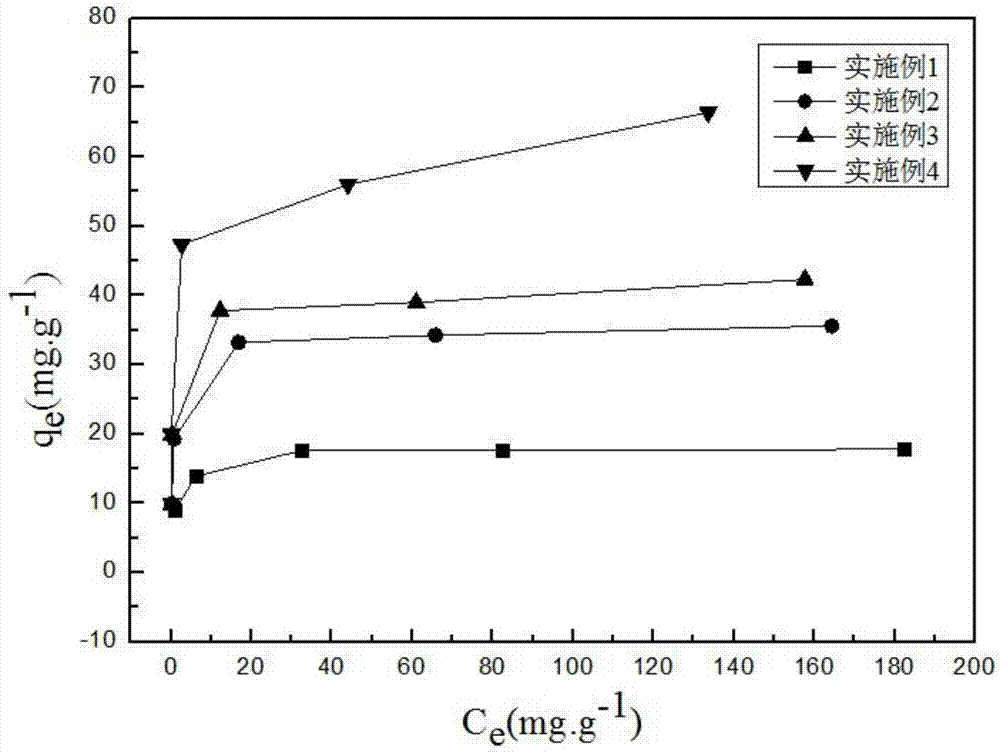

[0022] Example 1

[0023] (1) Dissolve 2ml of titanium isopropoxide and 0.185g of dodecylamine in 80ml of ethylene glycol, add 0.46g of ferrous sulfate heptahydrate after stirring for 8 hours, continue to stir until it is dissolved, and obtain solution A. Then measure 170ml of acetone and 2.7ml of water and mix evenly to obtain solution B. Pour solution A into B and stir for 3h, then centrifuge to obtain a solid product, wash it with ethanol several times, and vacuum dry at 40~90℃ for 8-12h to obtain Iron titanium compound

[0024] (2) Dissolve 1.2g of chitosan in 60ml of 1% acetic acid aqueous solution, stir for 24h, add 0.2g of iron-titanium compound, continue to stir for 2h, then add dropwise to 100ml of 1% sodium hydroxide solution to obtain The spherical particles with a diameter of 2-4 mm are then repeatedly washed with distilled water until the pH is neutral, dried at 30° C. and then freeze-dried for 12 hours to obtain chitosan-iron-titanium compound composite microspheres....

Example Embodiment

[0026] Example 2

[0027] The specific preparation process is the same as in Example 1, but the addition amount of iron and titanium in step (2) is 0.4 g.

[0028] The adsorption performance test process is the same as in Example 1. The maximum adsorption capacity of the adsorbent for lead ions in the corresponding solution is 35.6 mg / g.

Example Embodiment

[0029] Example 3

[0030] The specific preparation process is the same as in Example 1, but the addition amount of iron and titanium in step (2) is 0.6 g.

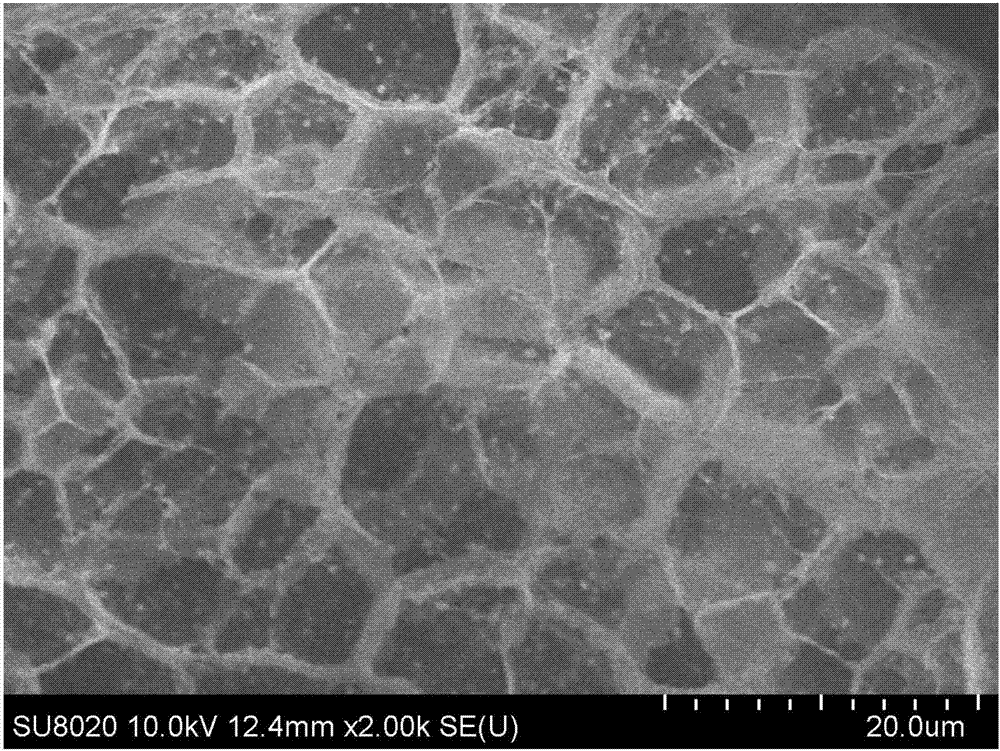

[0031] Scanning electron microscopy test: The chitosan-iron-titanium compound composite microspheres prepared above were tested by scanning electron microscopy. The test results are as follows figure 1 Shown.

[0032] figure 1 The scanning electron micrograph of the chitosan-iron-titanium compound composite microsphere particles with 0.6g of iron-titanium compound in this example is shown. From the figure, it can be seen that the main structure of the chitosan-iron-titanium compound composite microsphere is composed of chitosan. The sugar supports and presents a network structure, the spherical iron-titanium compound microspheres are relatively uniformly dispersed in the chitosan, and the average diameter of FeTi nanoparticles is about 400-500nm.

[0033] The adsorption performance test process is the same as in Example 1. The ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Maximum adsorption capacity | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap