Drawing die structure

A drawing die and die technology, applied in the field of drawing die die structure, can solve the problems that the press table cannot meet the requirements, the drawing die size is too long and wide, and the 2' width of the blank holder is large, etc. Thickness, reduced requirements, effect of size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0029] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

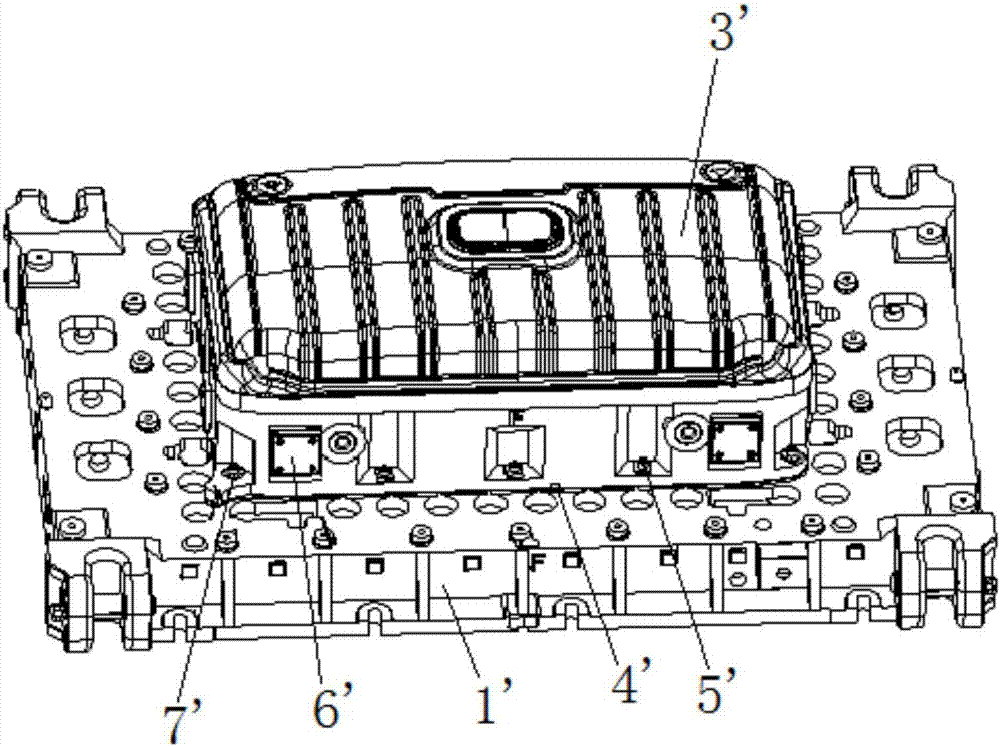

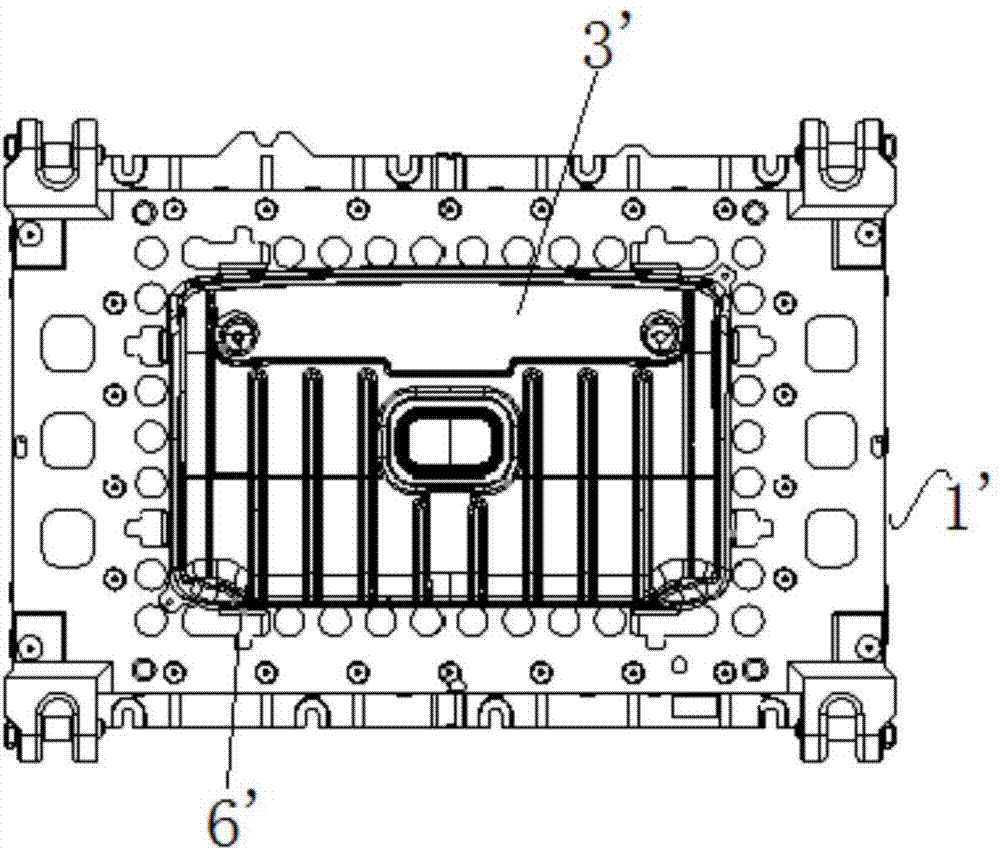

[0030] Figure 4 The schematic diagram of the installation of the punch and the punch seat proposed for the specific embodiment of the present invention; Figure 5 A schematic structural view of the punch seat proposed for a specific embodiment of the present invention; Image 6 The top view of the punch and the punch seat proposed for the specific embodiment of the present invention; Figure 7 It is a schematic structural diagram of a blank holder proposed in a specific embodiment of the present invention.

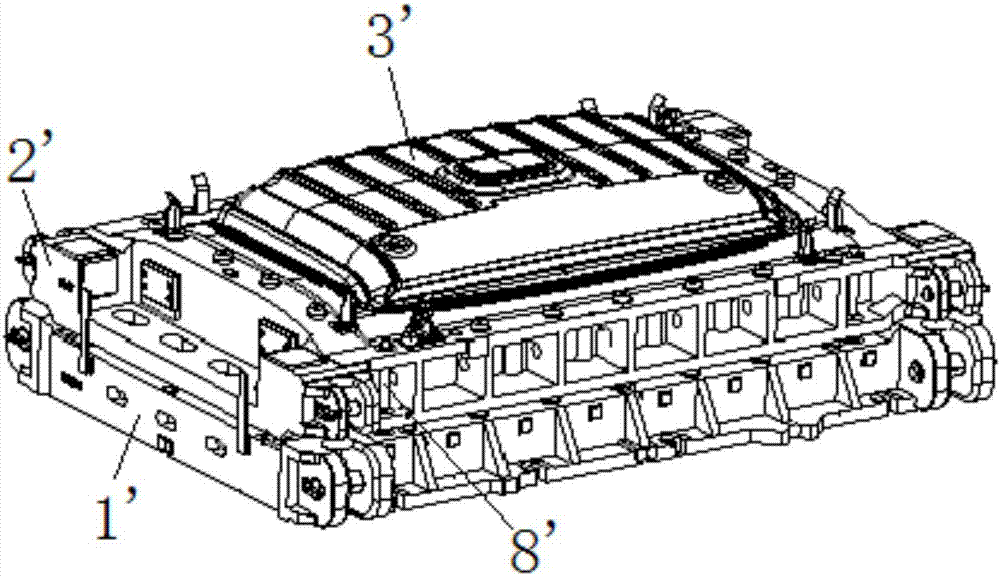

[0031] Please refer to Figure 4 to Figure 7 , the present invention proposes a drawing die structure, which includes a punch base 1, a blank holder 2, a punch 3 and a safety stroke bolt 8', and the punch base 1 is provided with a mounting platform 4, so The punch 3 is installed on t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap