Robot automatic welding line for self-propelled maize harvesting machine chassis

A corn harvester and welding line technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of automatic welding lines without robots, reduce line deformation and distortion, ensure welding quality, and improve utilization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

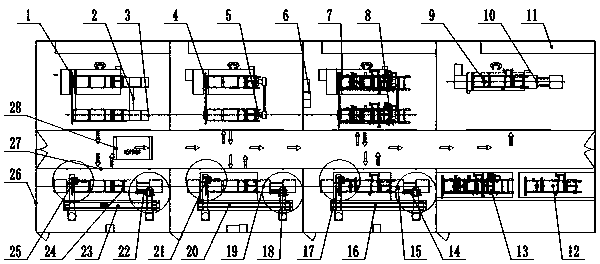

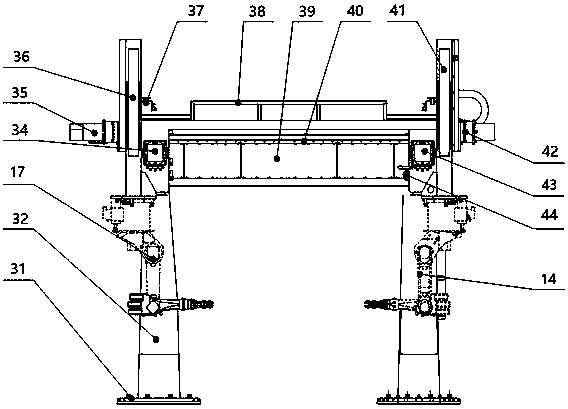

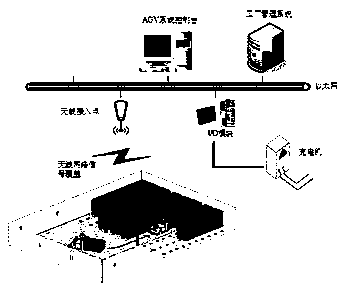

[0015] The self-propelled corn harvester chassis robot automatic welding line of the present invention consists of flexible pairing fixture I1, automatic conveyor 2, buffer tooling I3, flexible pairing fixture II4, buffer tooling II5, PLC controller 6, flexible pairing Fixture Ⅲ7, buffer tooling Ⅲ8, repair welding fixture 9, lifting positioner 10, parts rack 11, semi-finished buffer tooling 12, finished product buffer tooling 13, welding robot Ⅵ14, rotary positioner Ⅲ15, double-axis gantry slide table Ⅲ16, Welding robot Ⅴ17, welding robot Ⅳ18, rotary positioner Ⅱ19, double-axis gantry slide Ⅱ20, welding robot Ⅲ21, welding robot Ⅱ22, double-axis gantry slide Ⅰ23, rotary positioner Ⅰ24, welding robot Ⅰ25, fence 26, shading Board 27, AGV logistics vehicle 28 and other parts.

[0016] The manual butt welding station of the welding line is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com